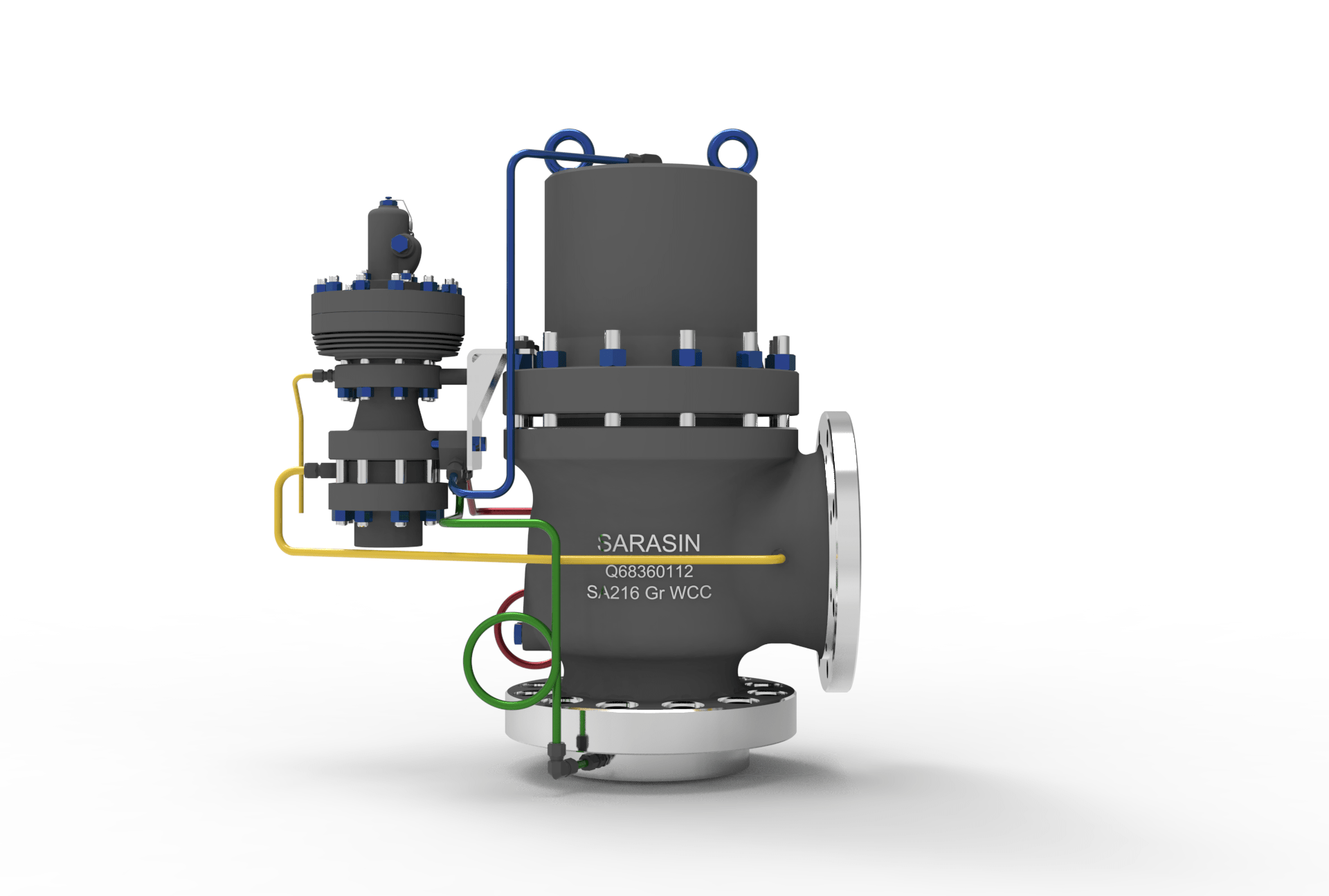

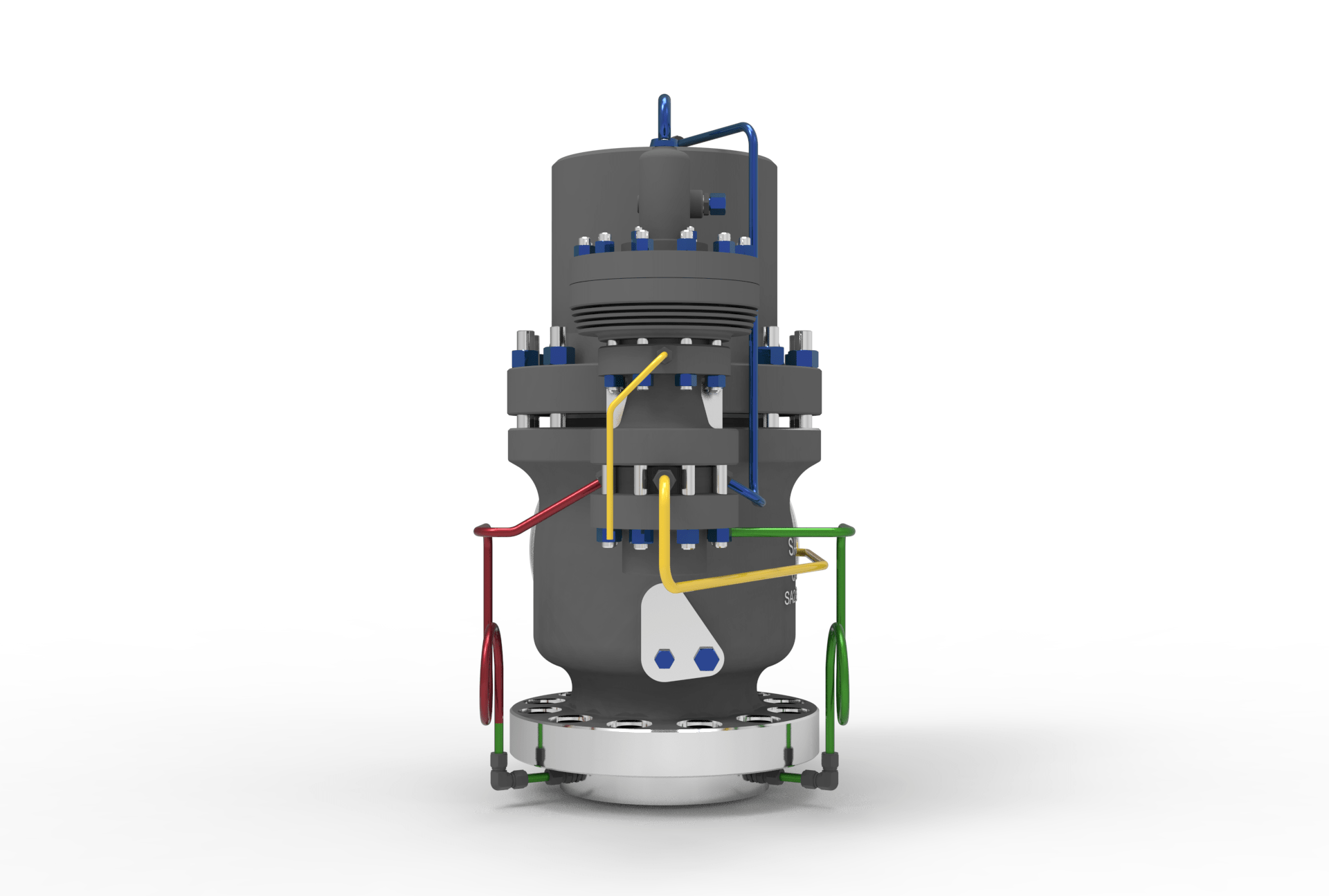

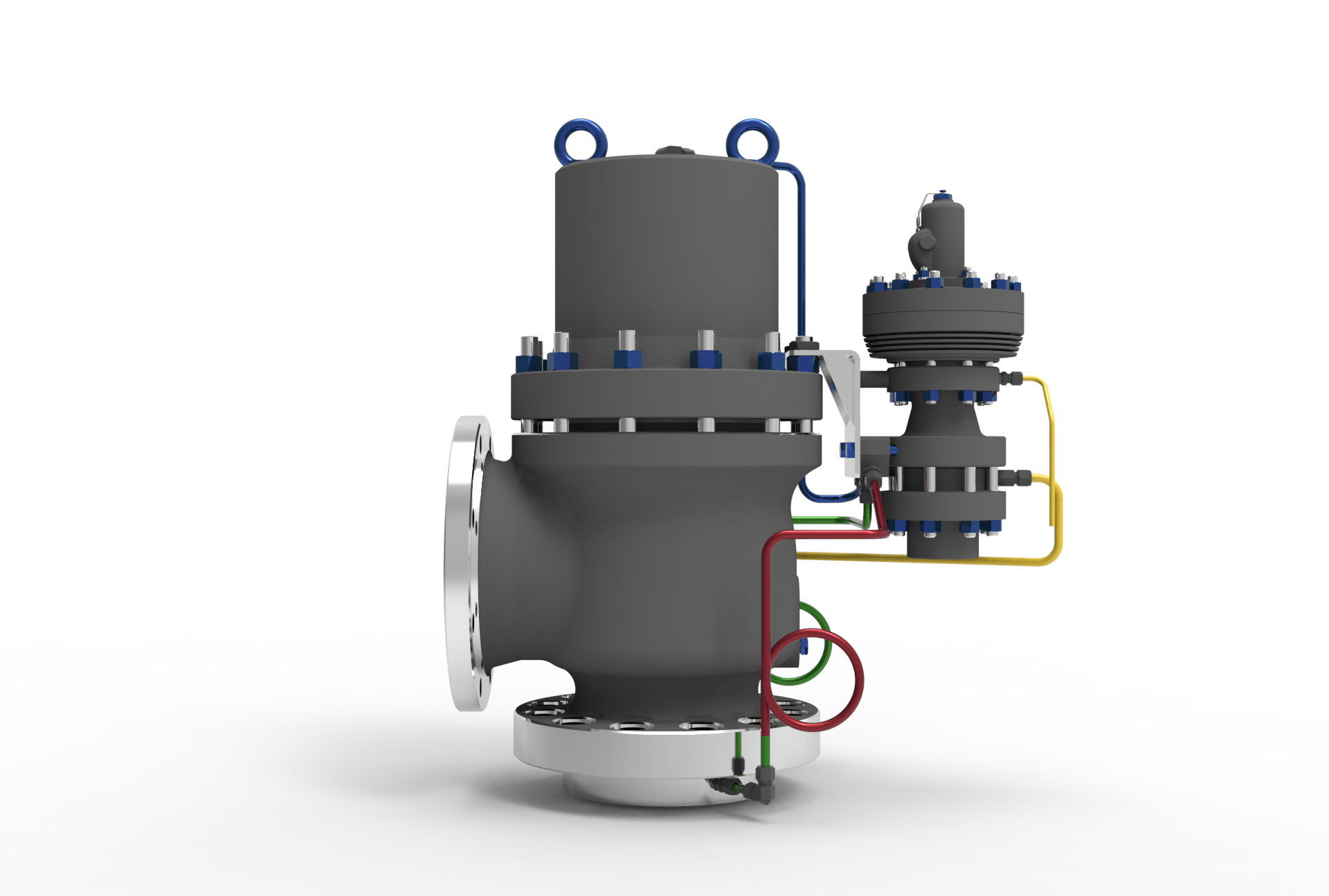

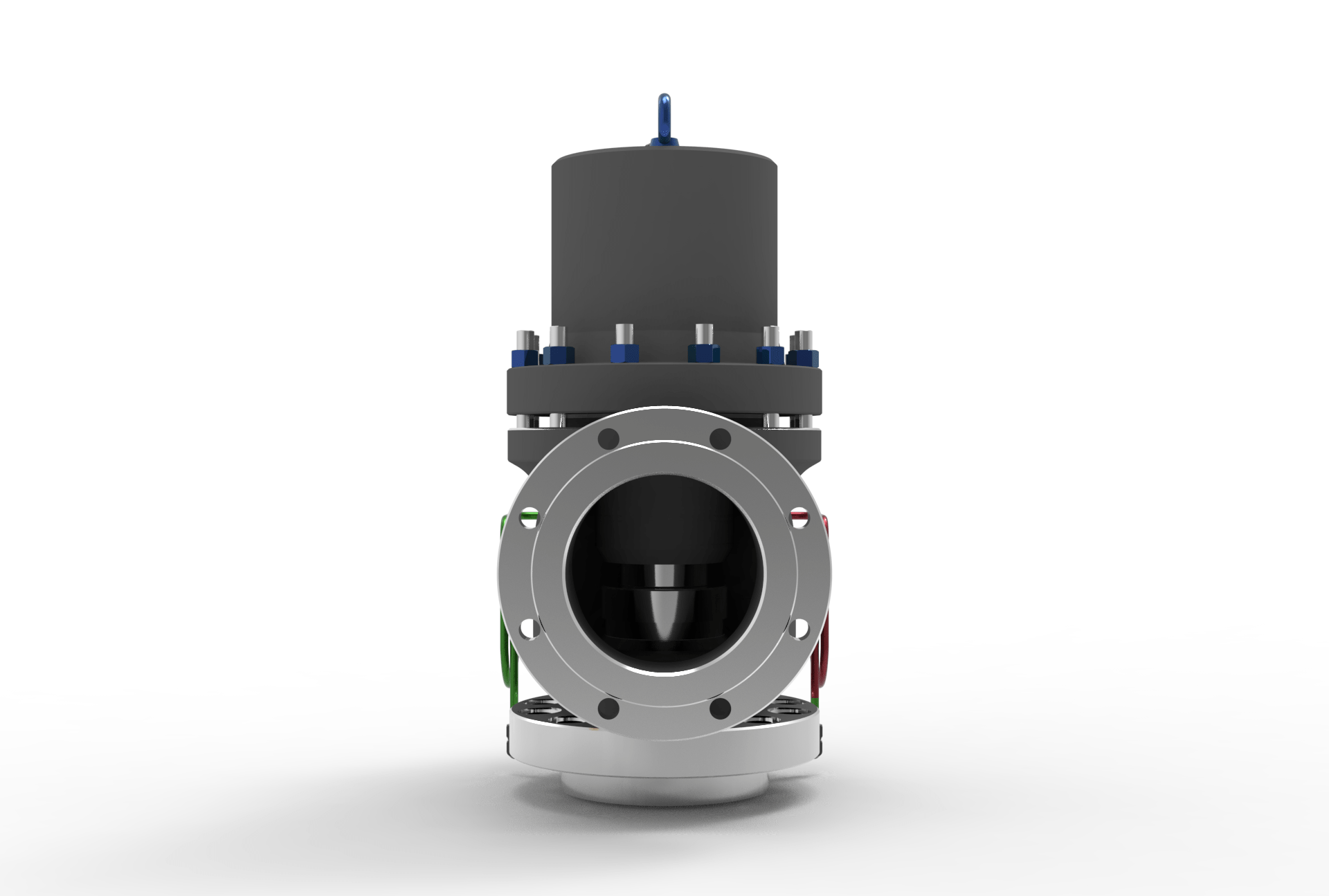

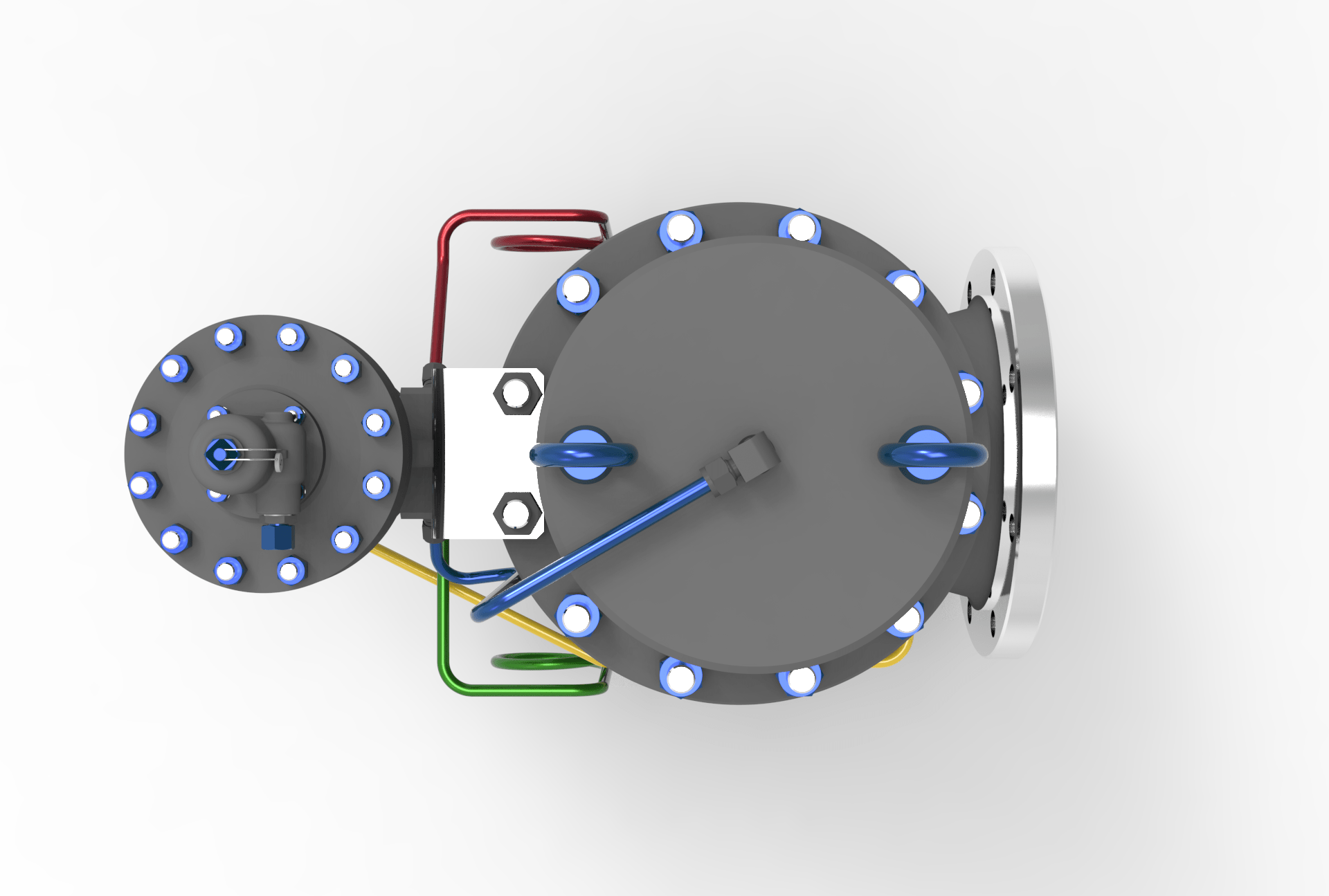

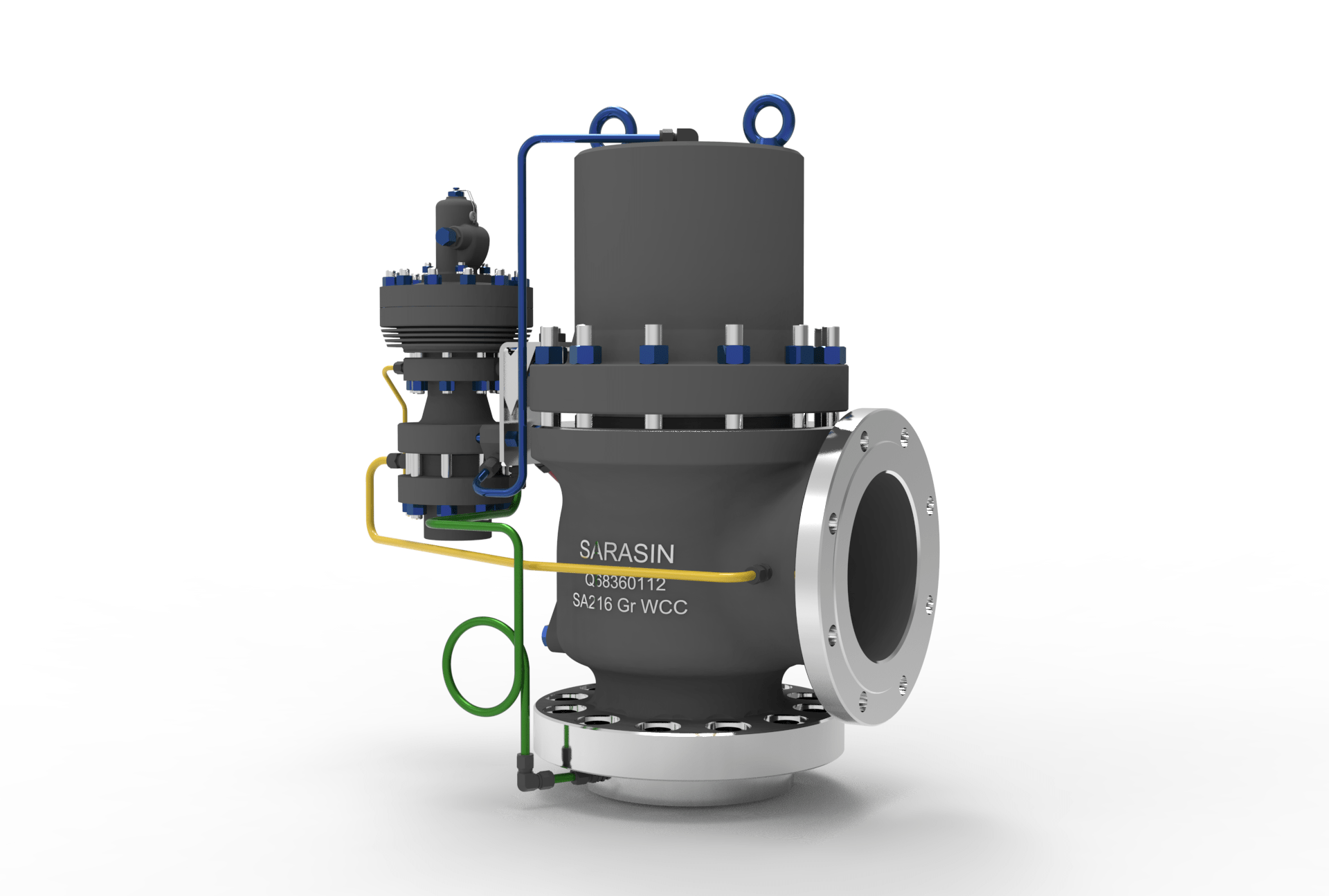

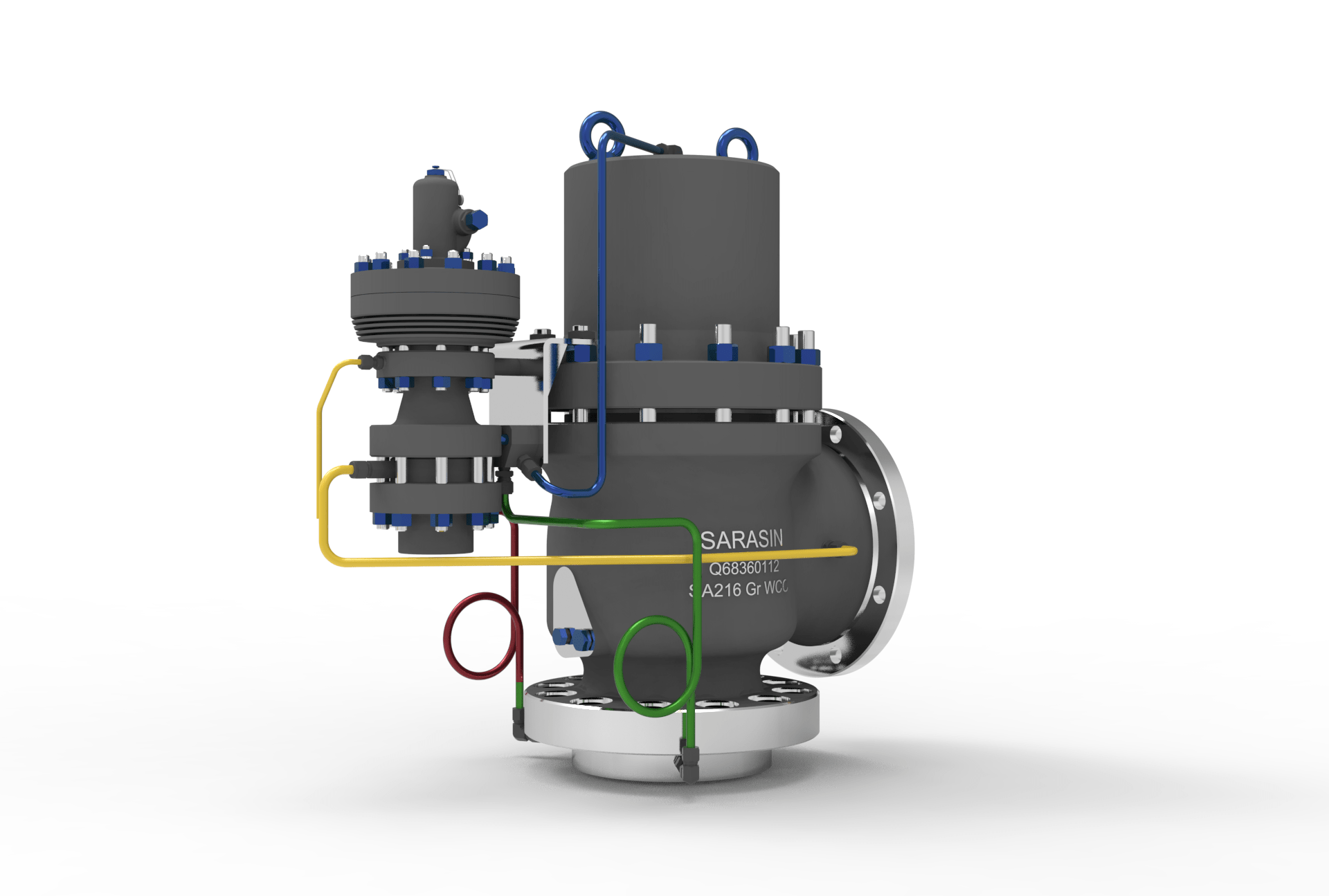

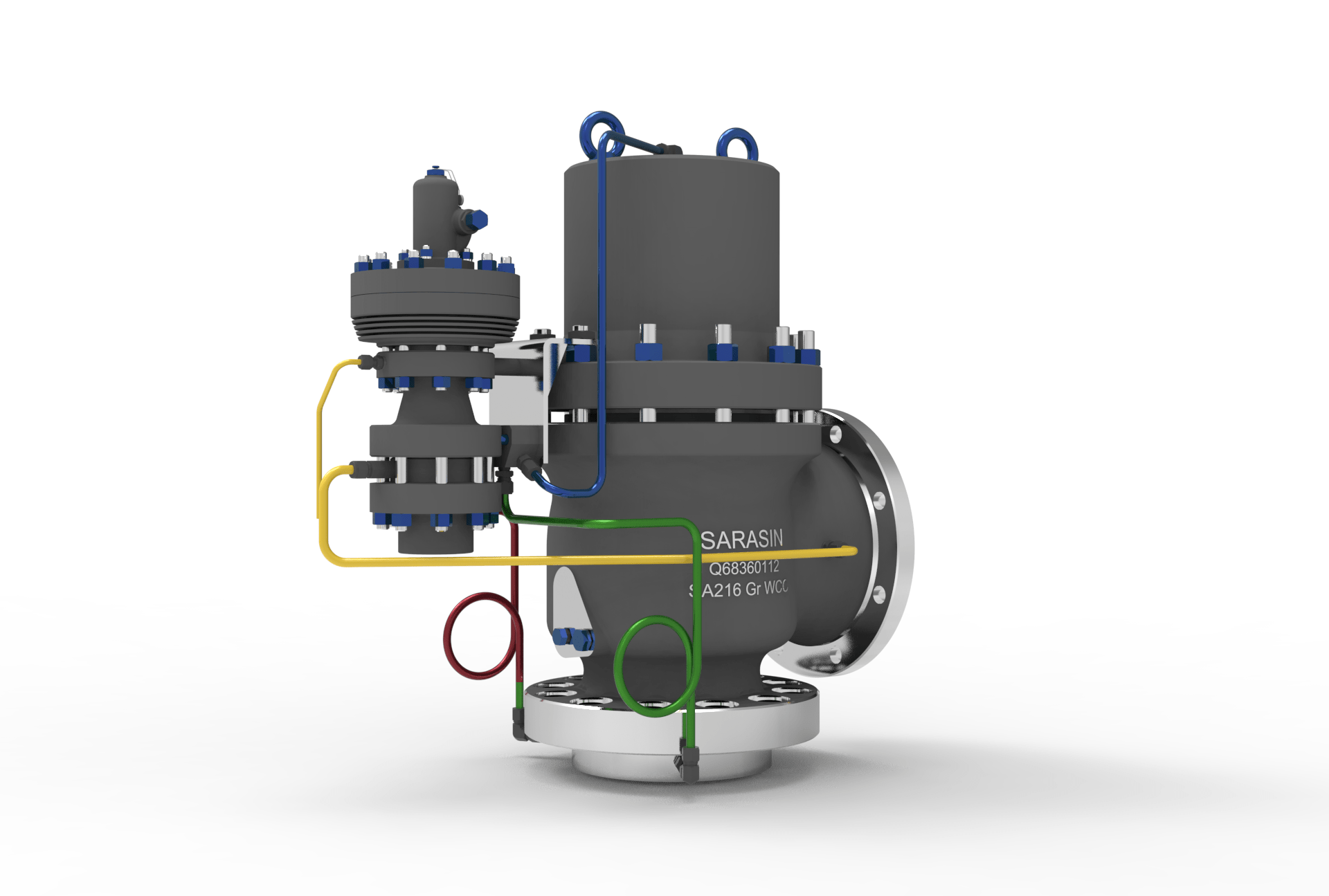

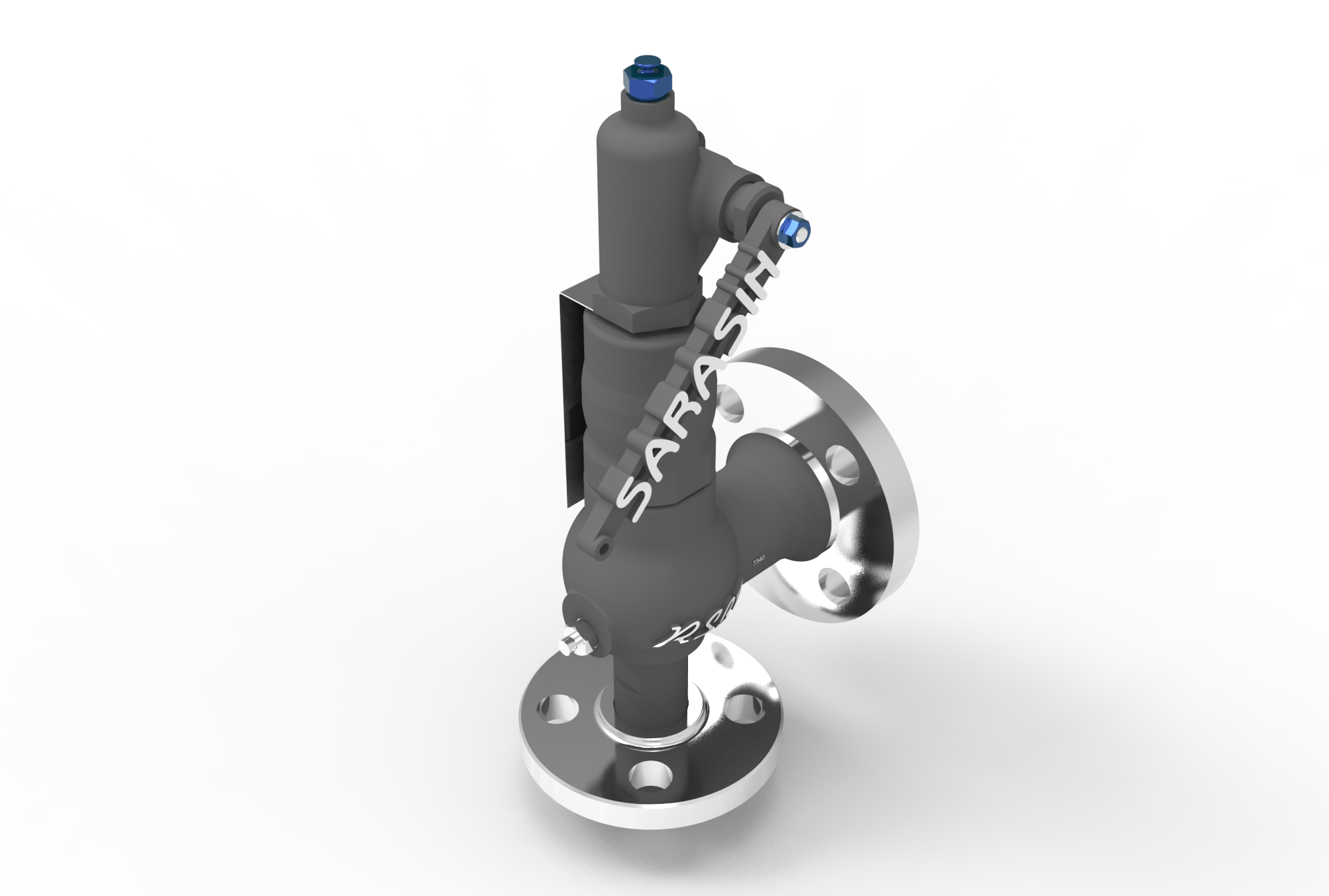

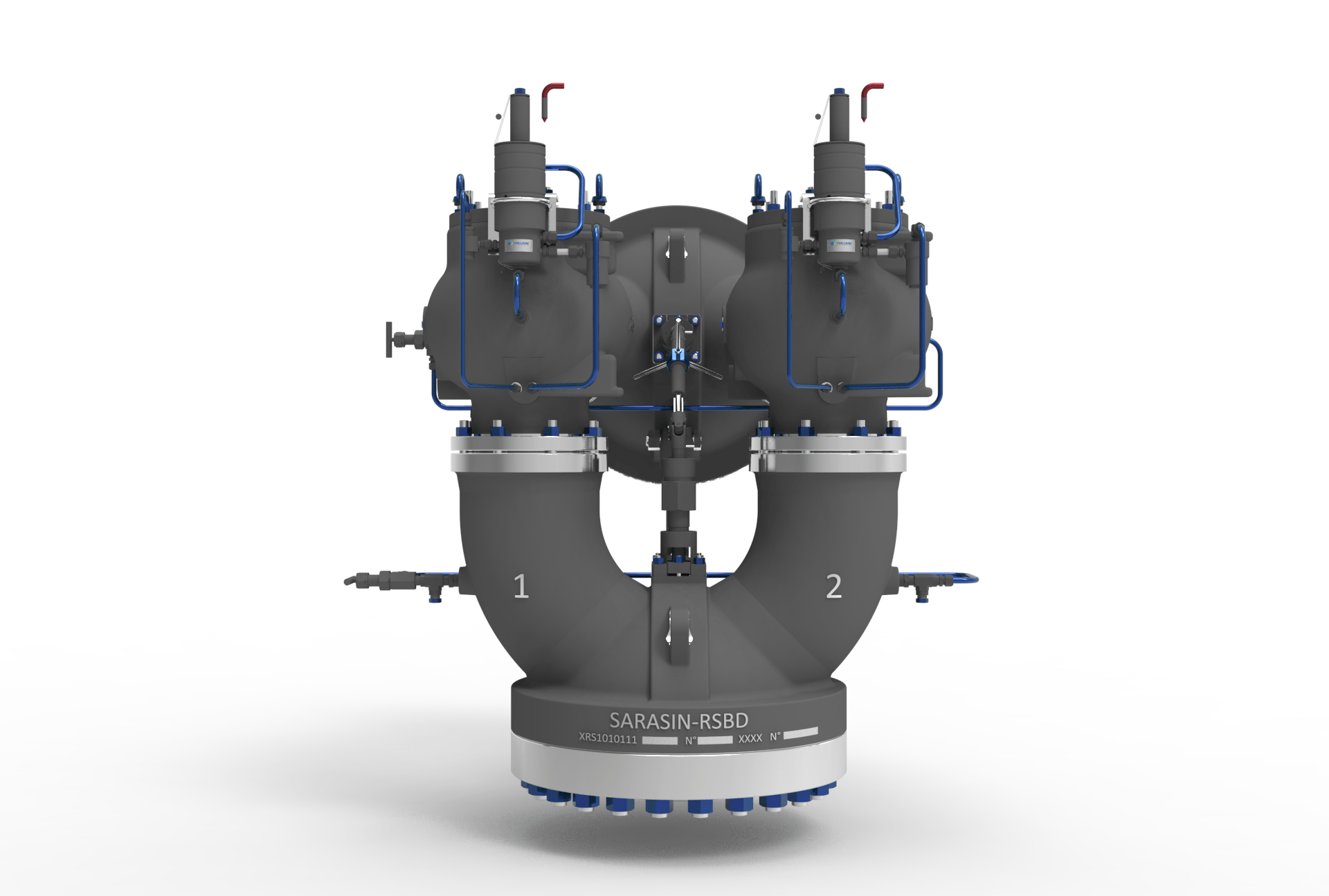

Sarasin-RSBD®

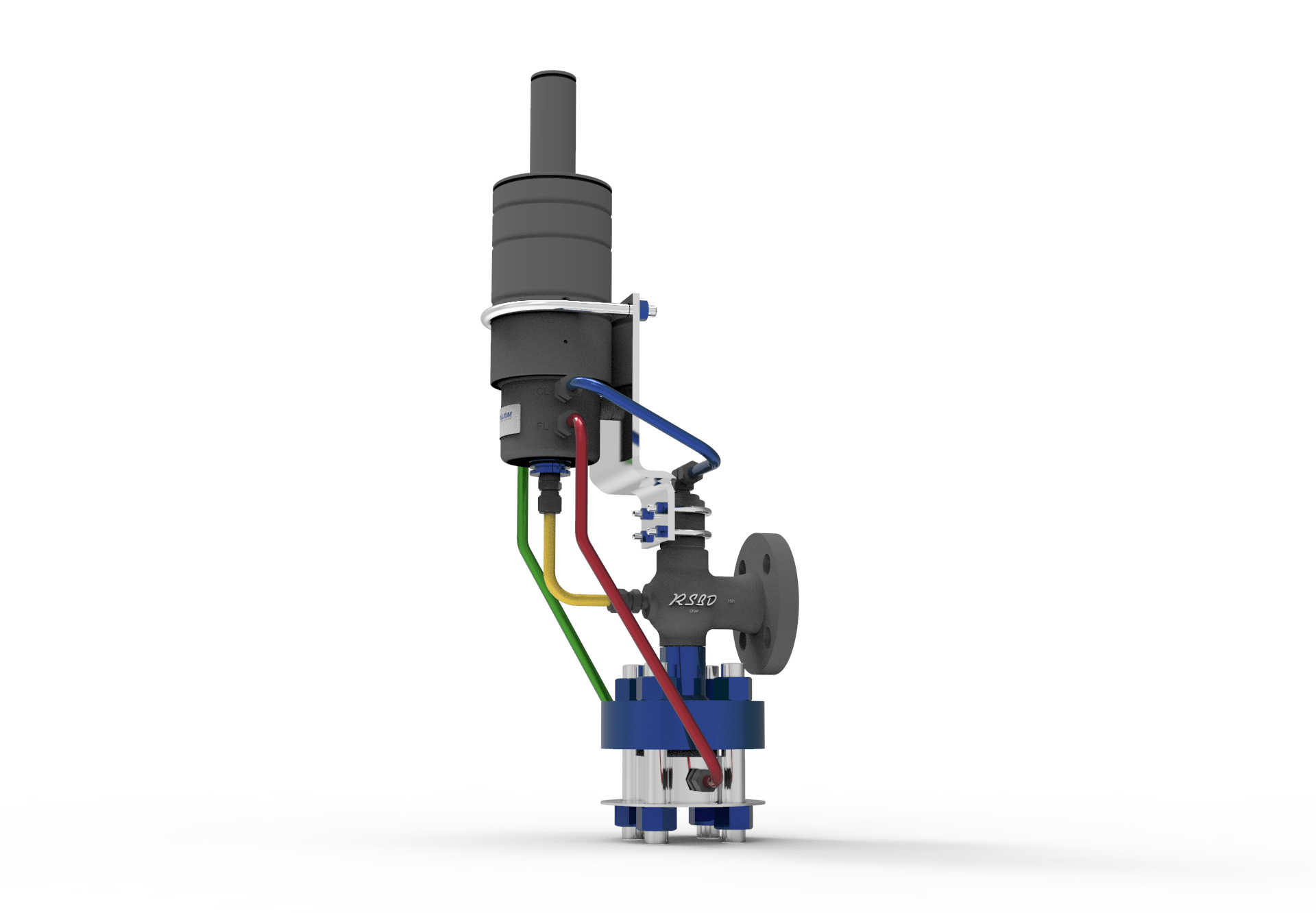

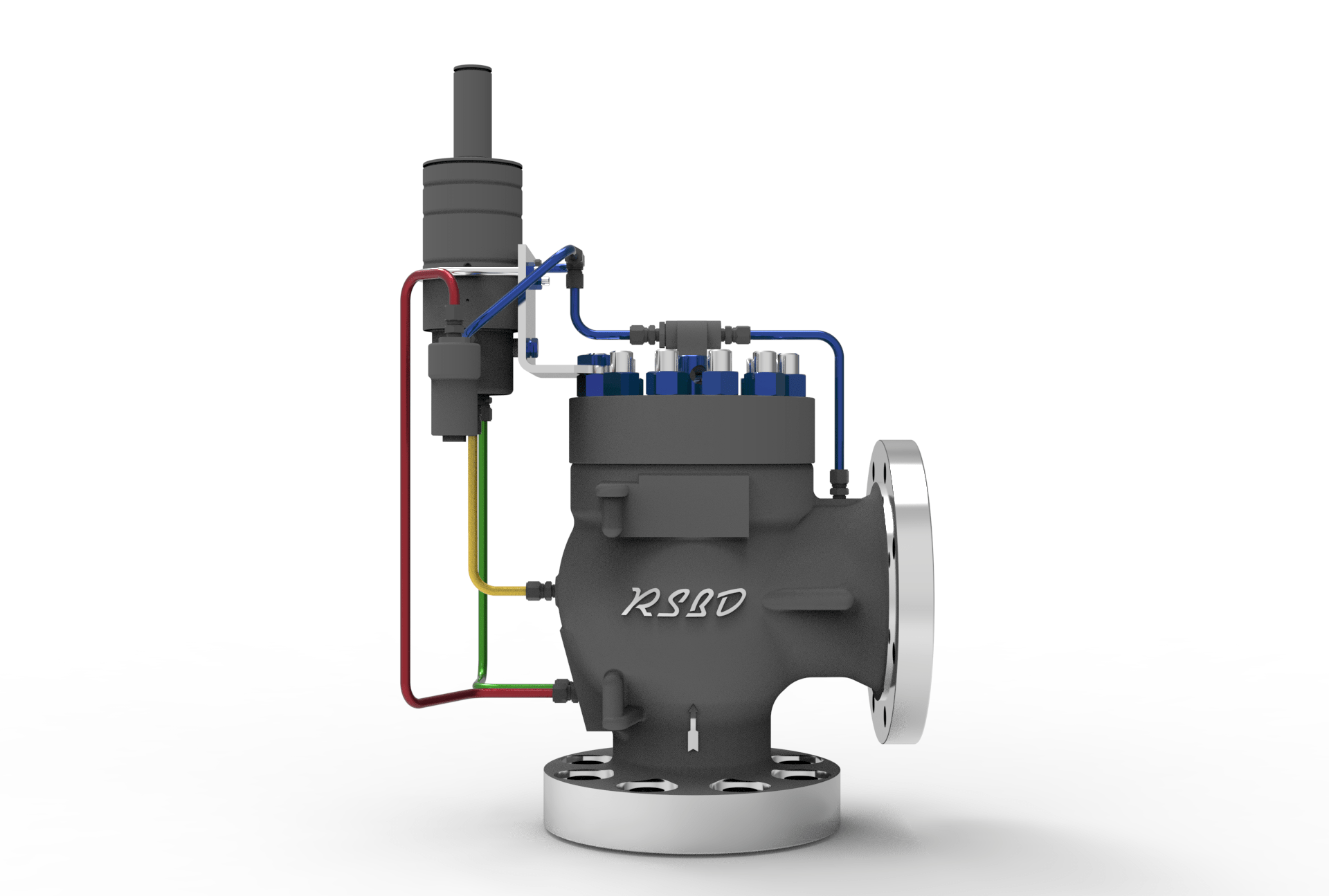

86 Series Pilot Operated Pressure Relief Valve

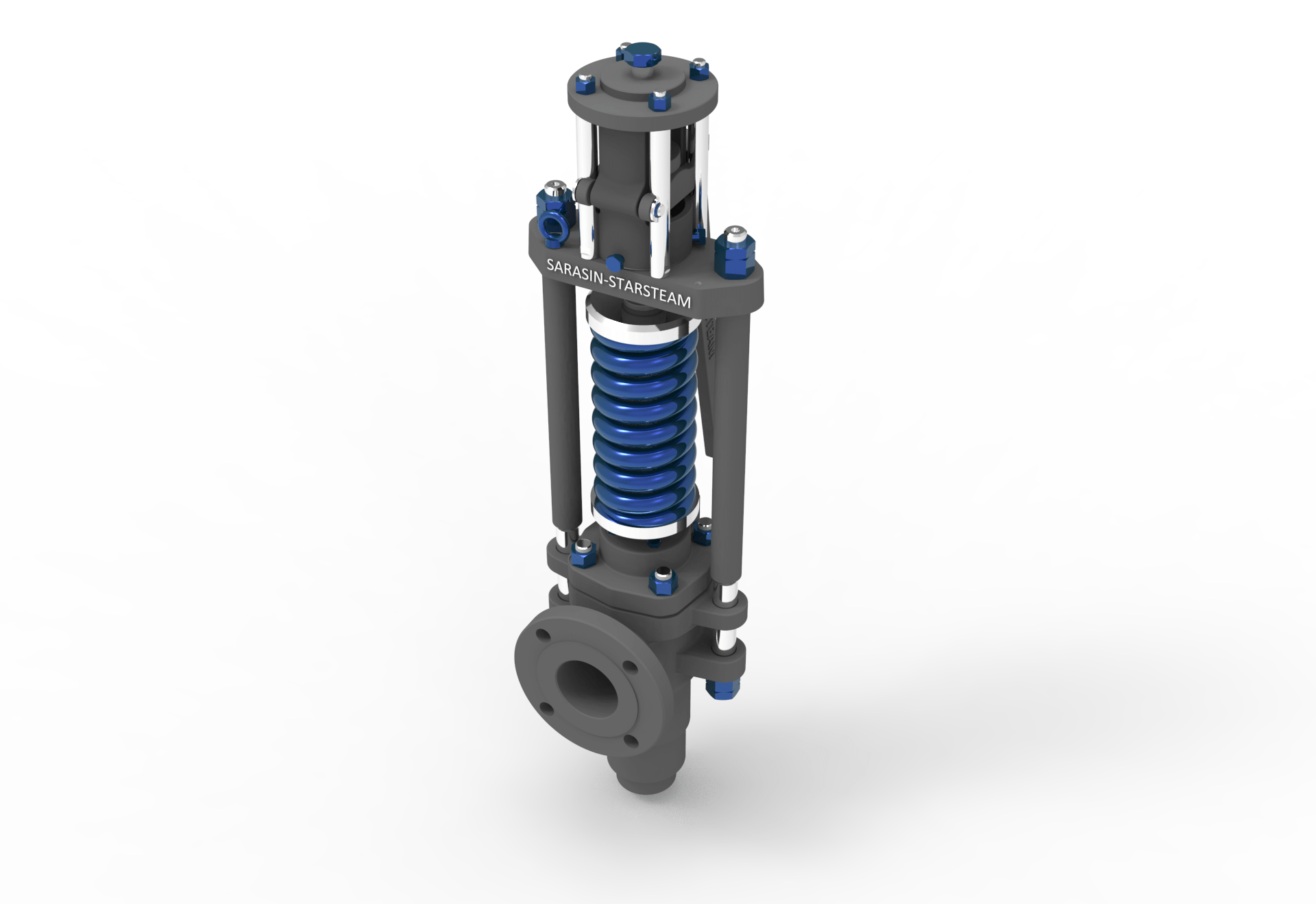

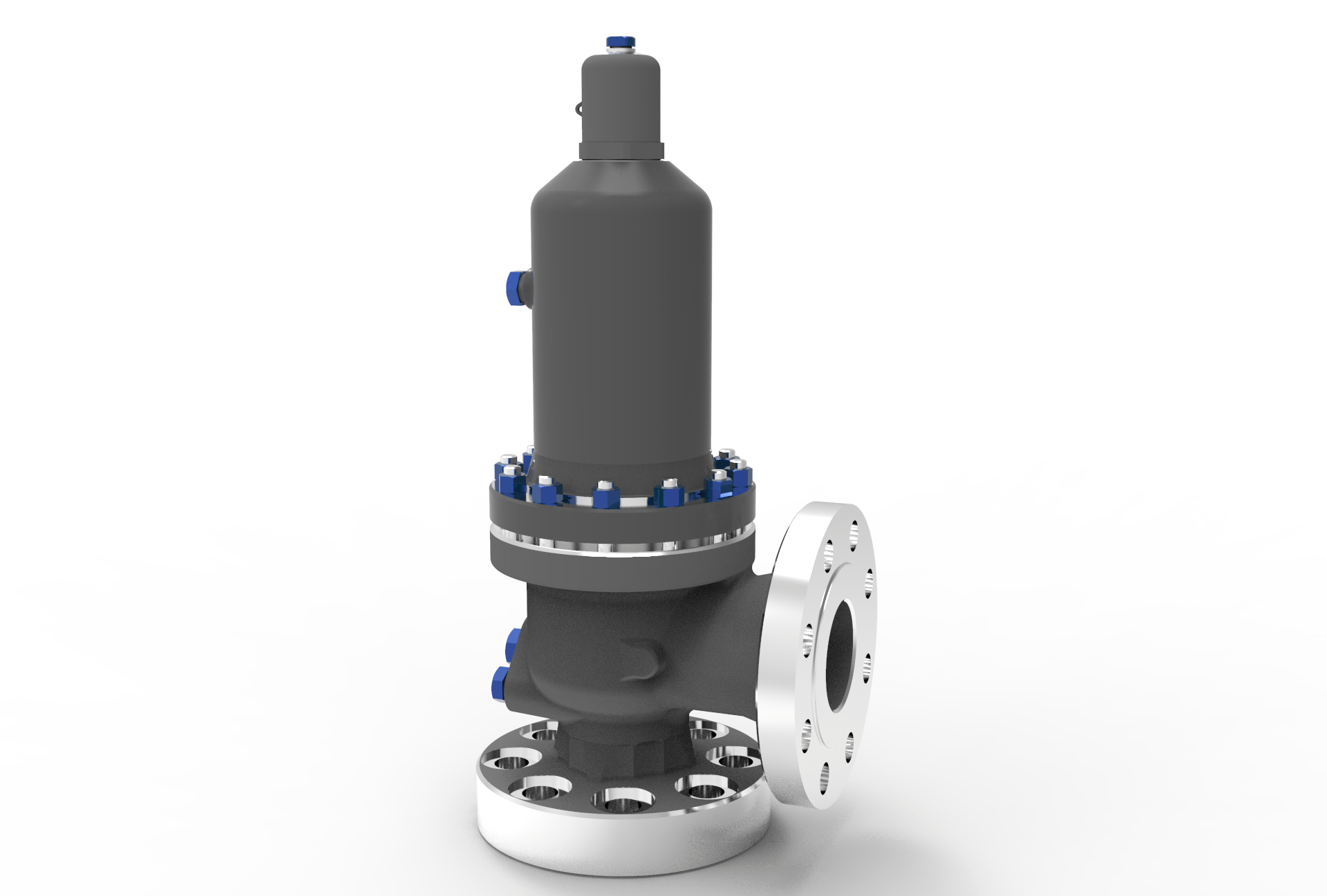

The Sarasin-RSBD® 86 Series Full Nozzle design is based on our experience in nuclear applications.

It has been developed to protect the drum and superheater and to comply with local regulations where isolated steam from the atmosphere and remote sensing line are mandatory.

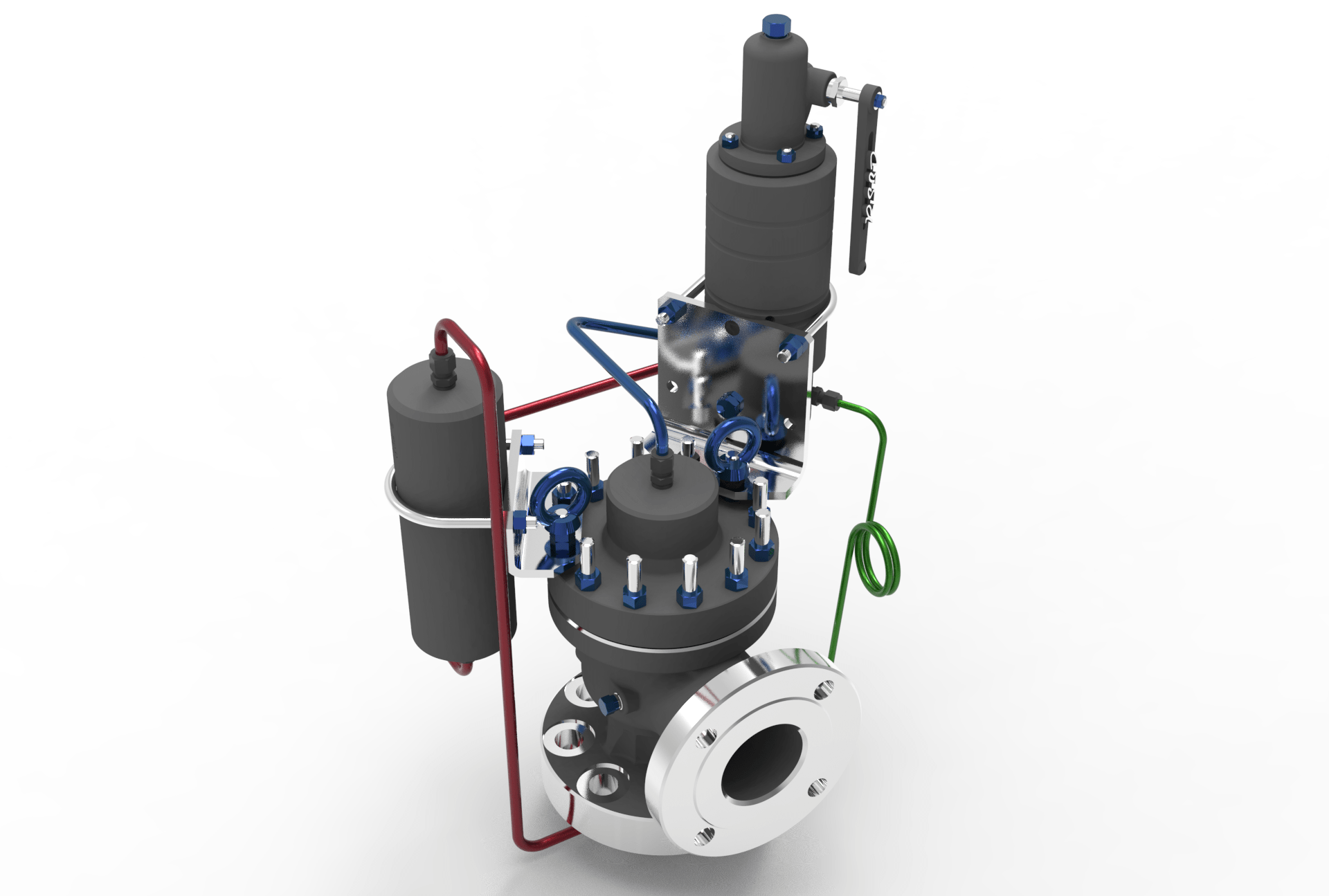

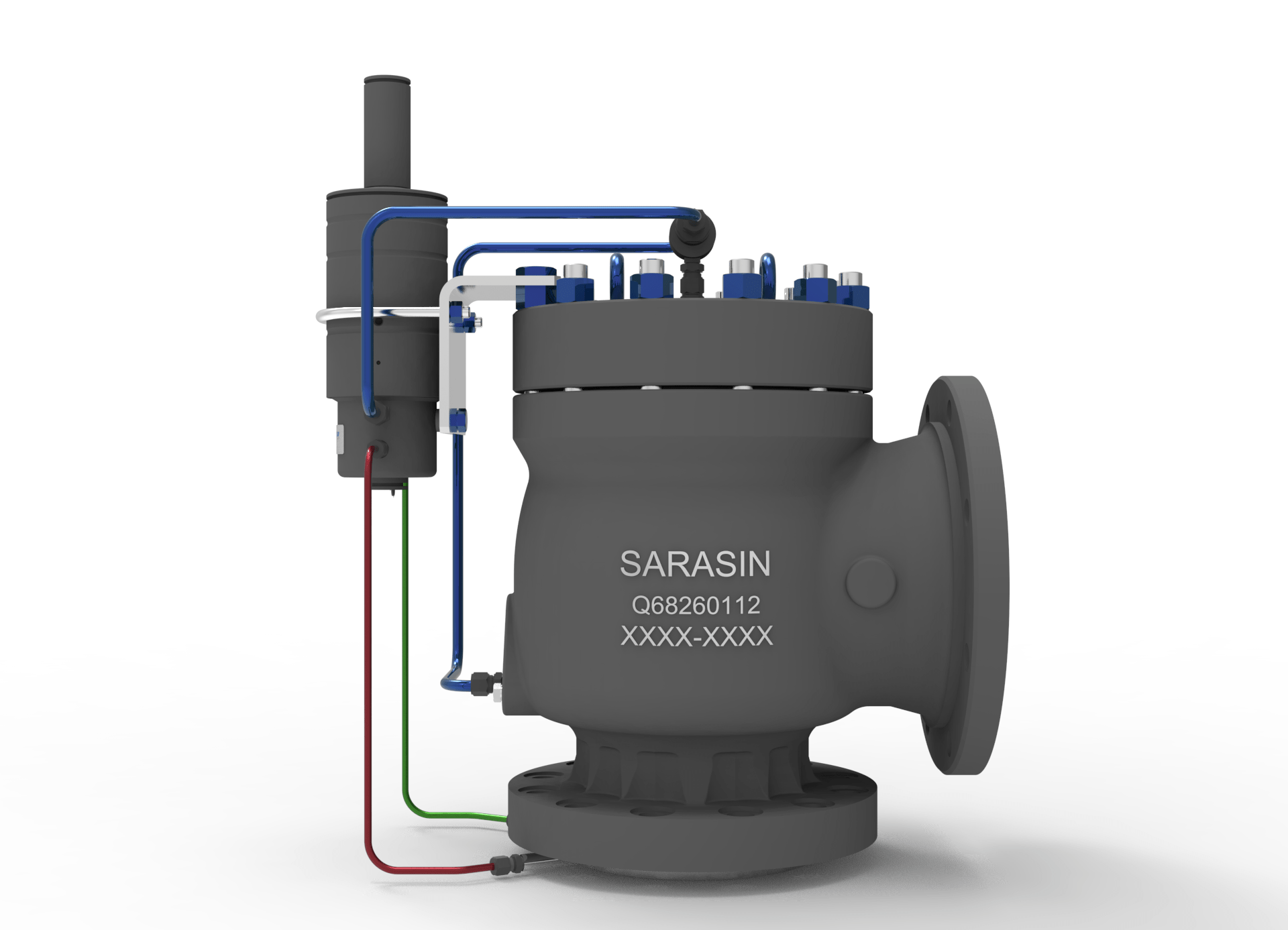

The Sarasin-RSBD® 86 Series Pilot Operated Pressure Relief Valve has been developed to address high temperature steam requirements.

This new design and material is based on our extensive experience in nuclear applications. The DMS technology is the same technology that is currently used by SEBIM® in nuclear power plants.

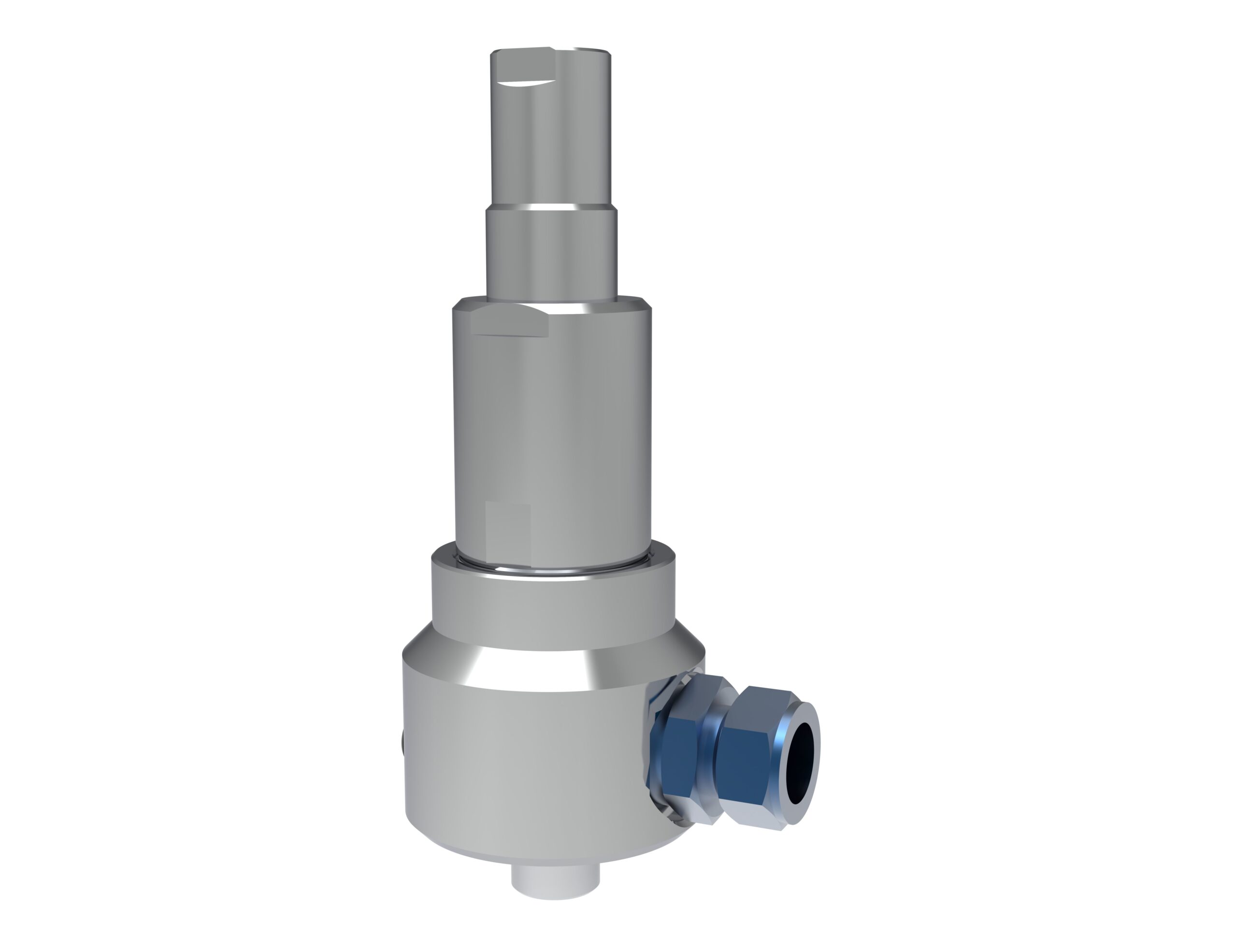

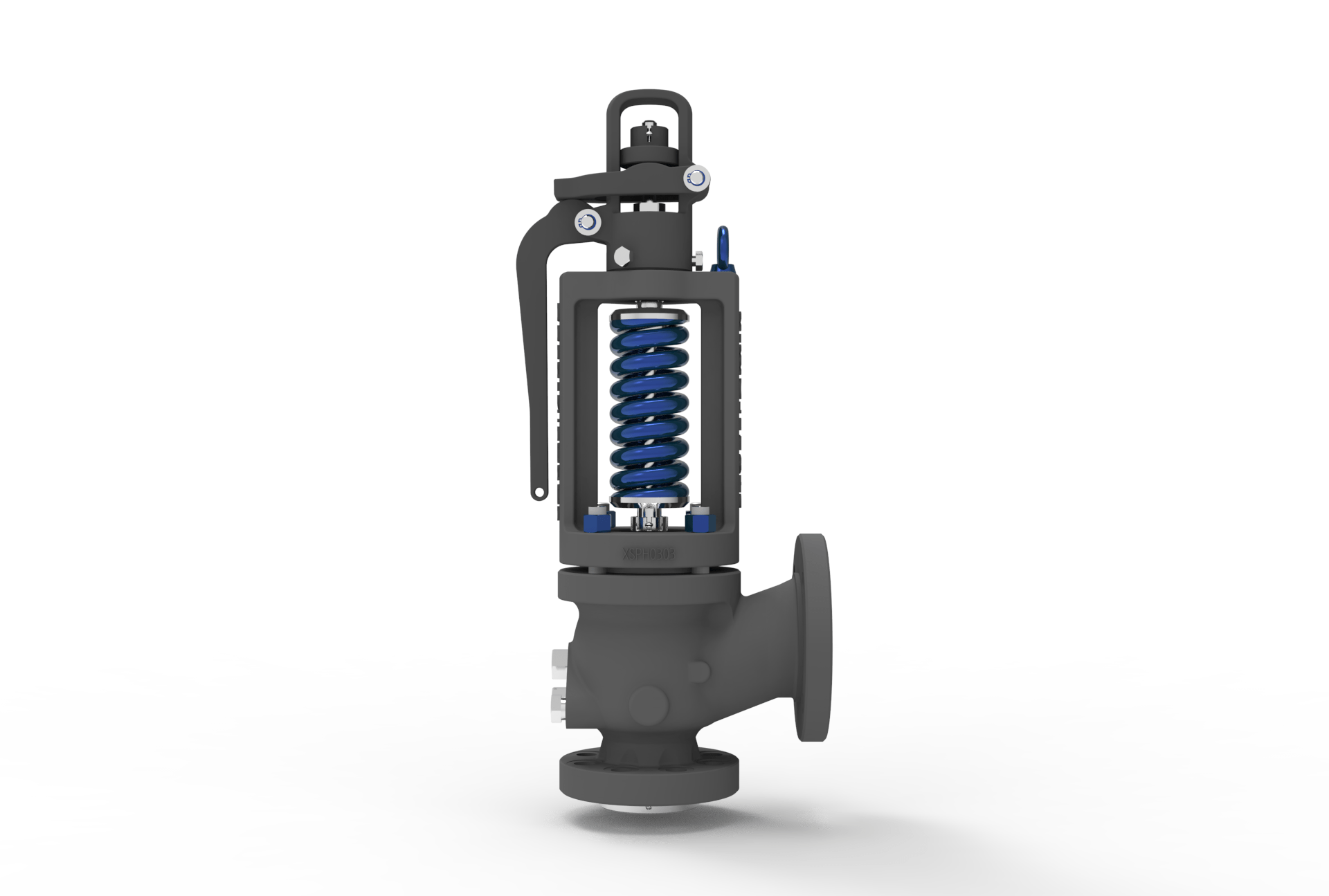

The design of the valve seal is performed without any elastomer. The main valve dome and DMS pilot sealing is insured by metallic bellows. This feature allows the pilot operated pressure relief valve to keep a constant steam flow through the DMS pilot and the main valve without any impact on valve performance.

“Hang-up” of guiding surfaces associated with comparable valves is eliminated with a unique anti-sizing feature. This is the first pilot operated pressure relief valve in the world to offer this technology to prevent this kind of failure.

DESIGN STANDARDS

- ASME BPVC Section VIII

- ISO 4126

- Directive 2014/68/UE|

- ATEX 94/9/EC

- EAC TR CU 10/12/32

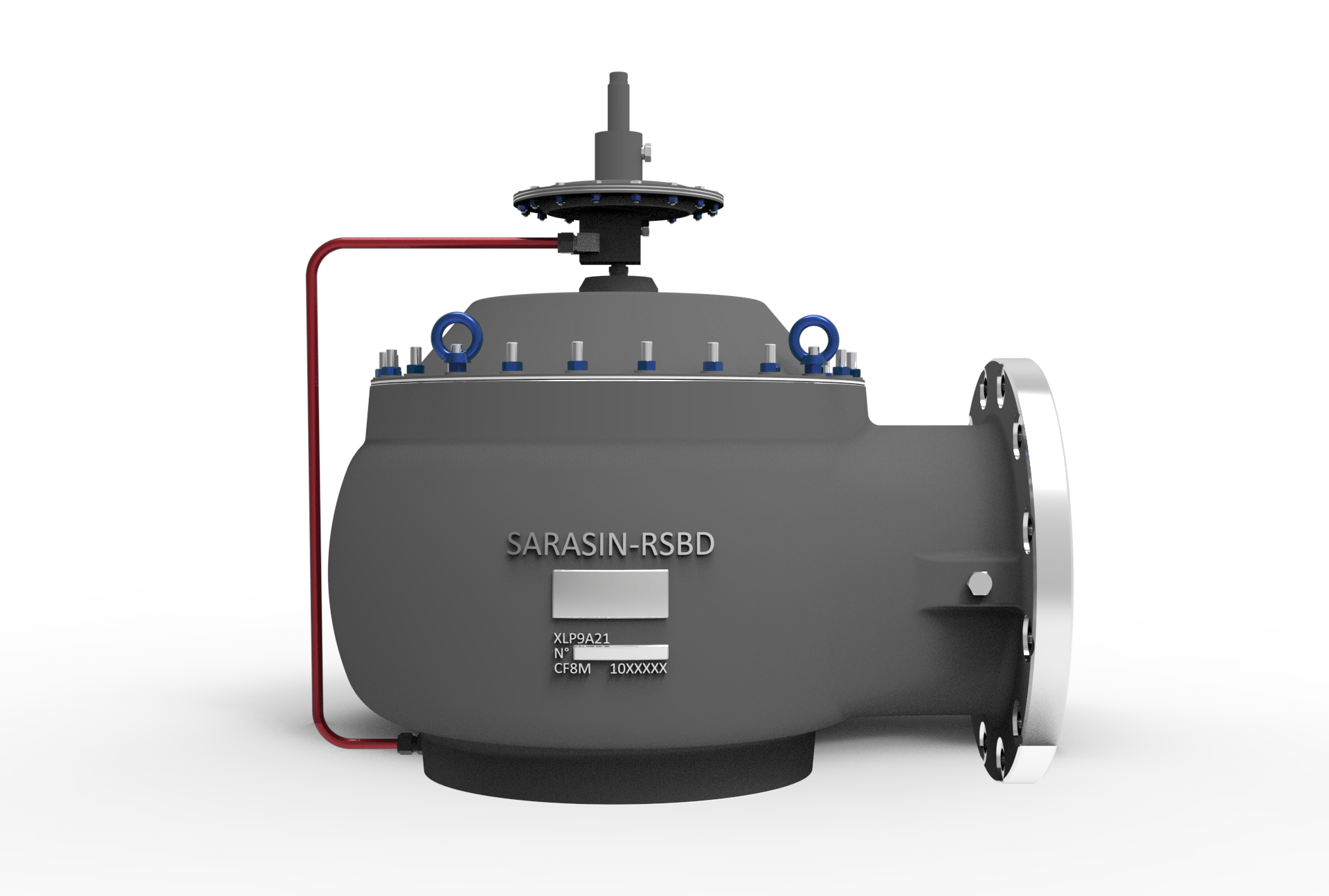

PRESSURE RANGE

- Up to 180 bar (2,610 psig)

CAPACITY

- Individually calculated and selected for each process application

MATERIALS

- SA216 Gr. WCC

- SA217 Gr. WC6/WC9/C12A

- SA351 Gr. CF8M

DESIGN RATINGS

- ASME & API Class 150 to 2500

- API Class 5K & 10K (customized)

SIZE RANGE & DIMENSIONS

- 25 – 200mm (1 – 8 inches)

TEMPERATURE RANGE

- Up to 590°C (1094°F)

SEAT TIGHTNESS

- 95%