Red Point®

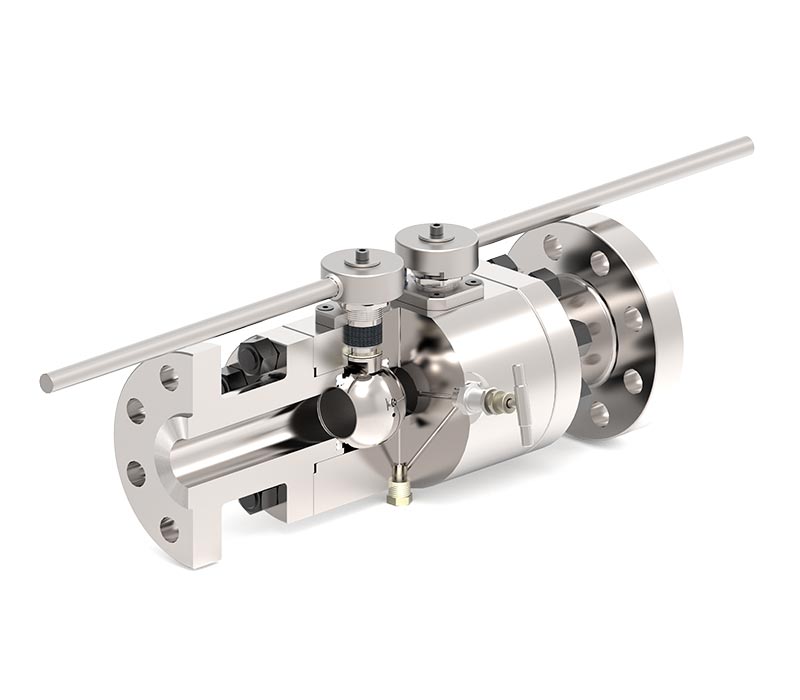

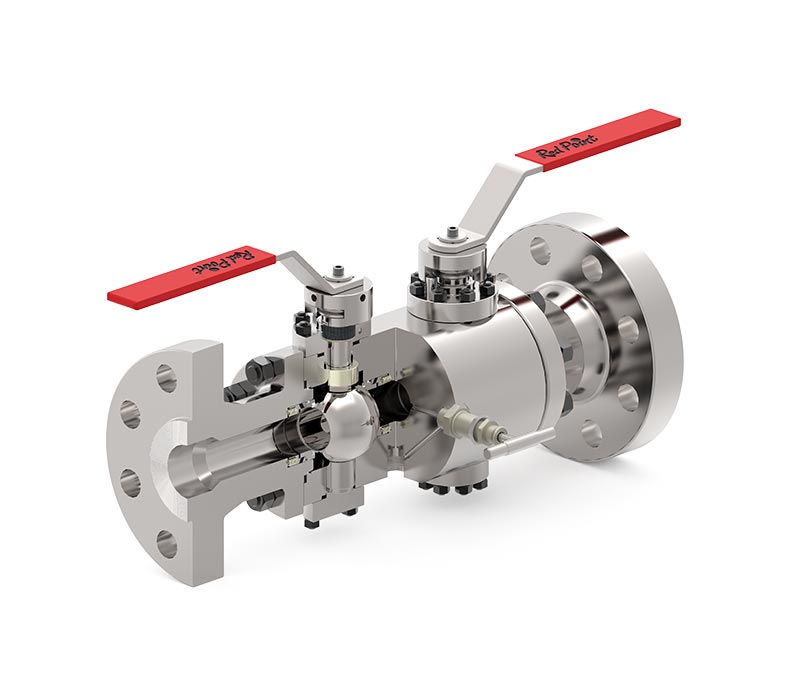

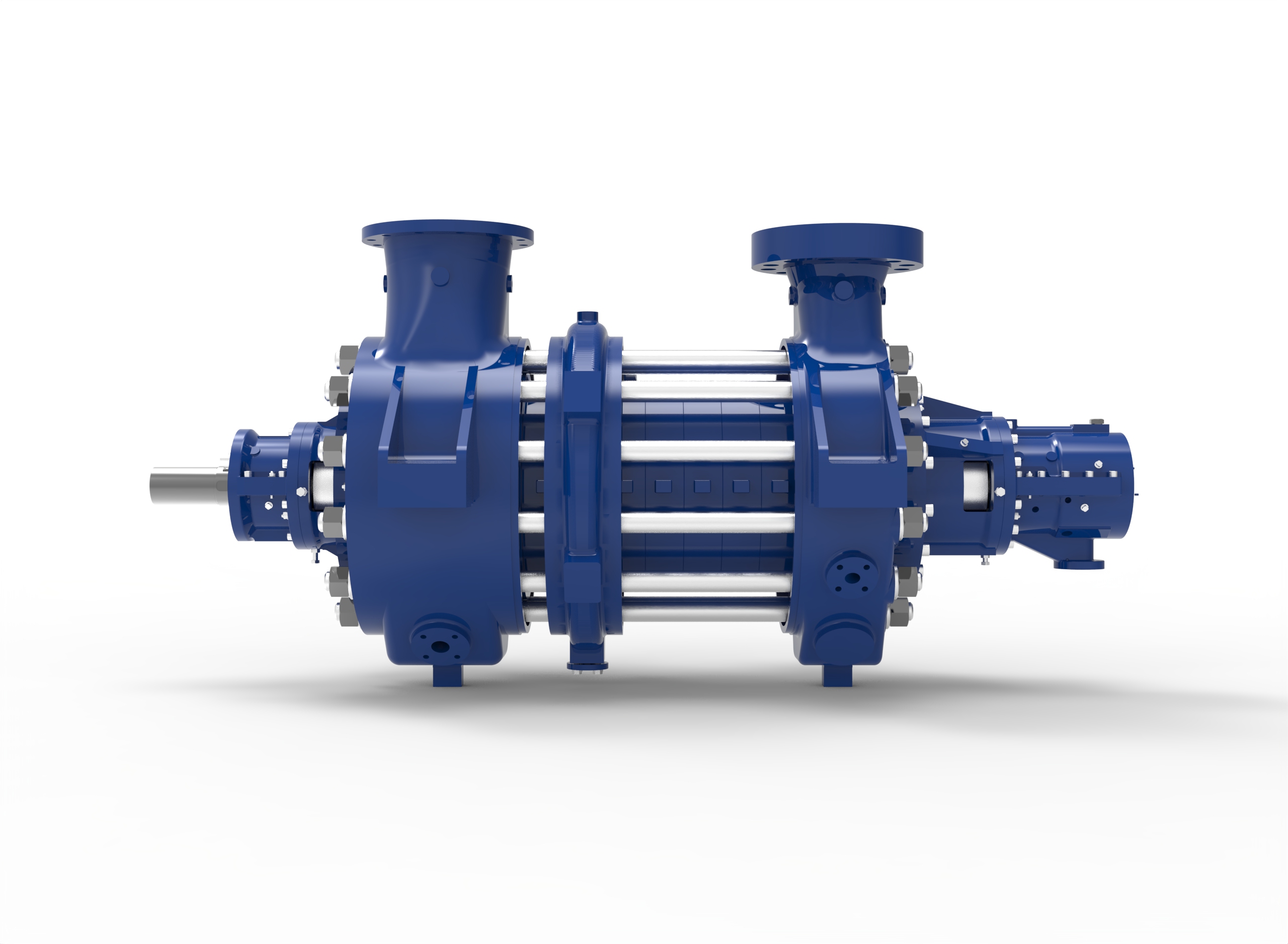

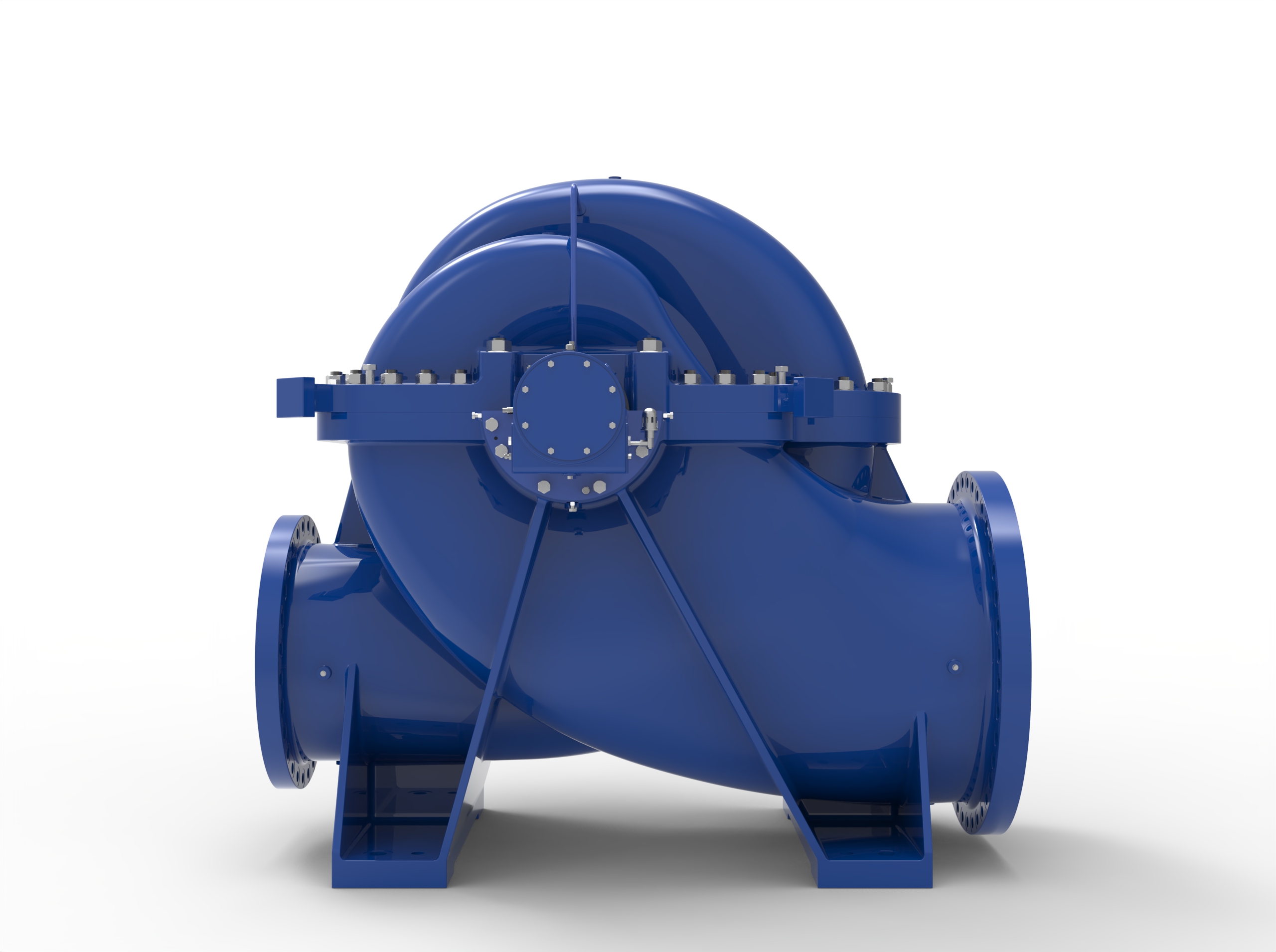

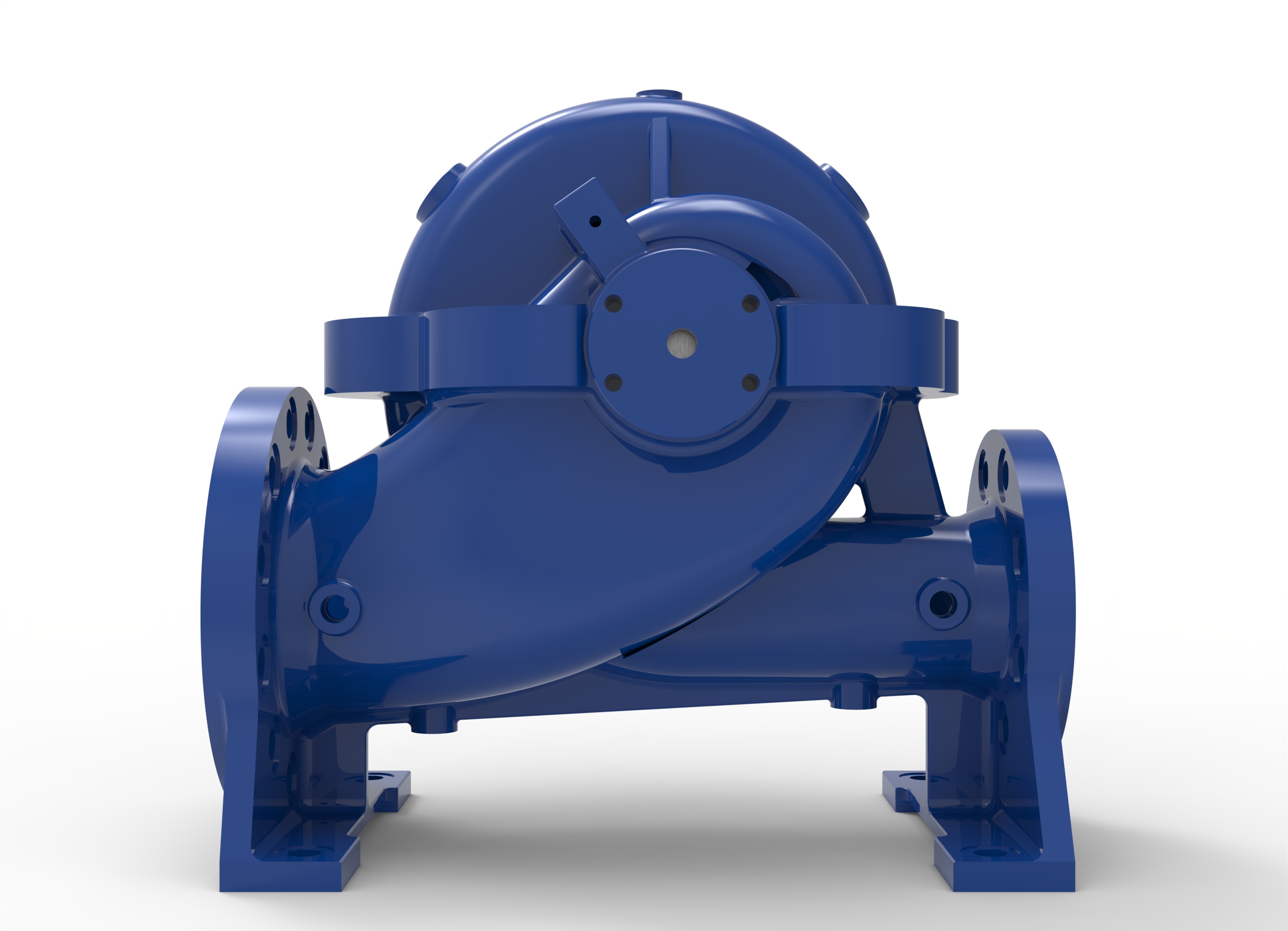

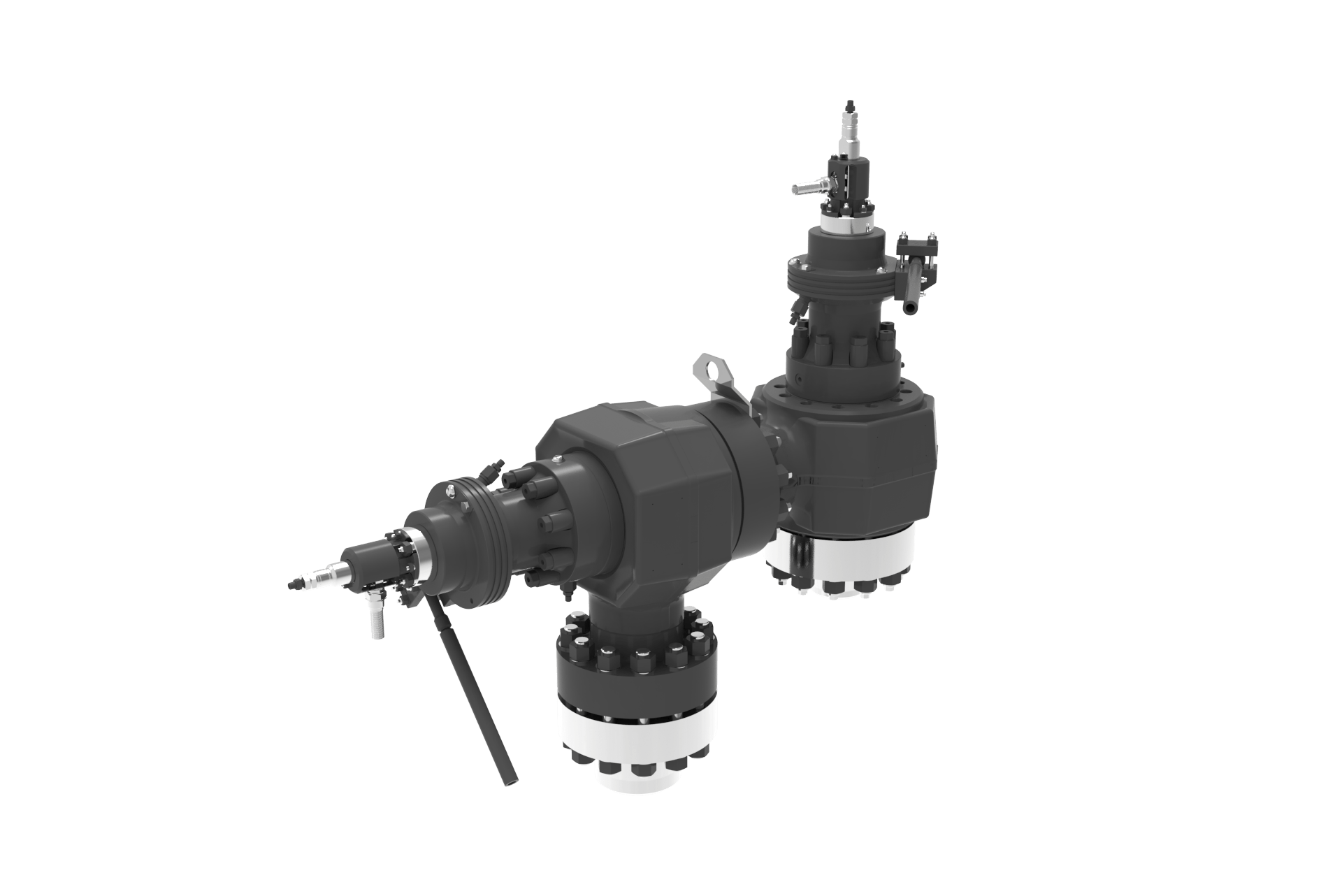

Double Block & Bleed Valves

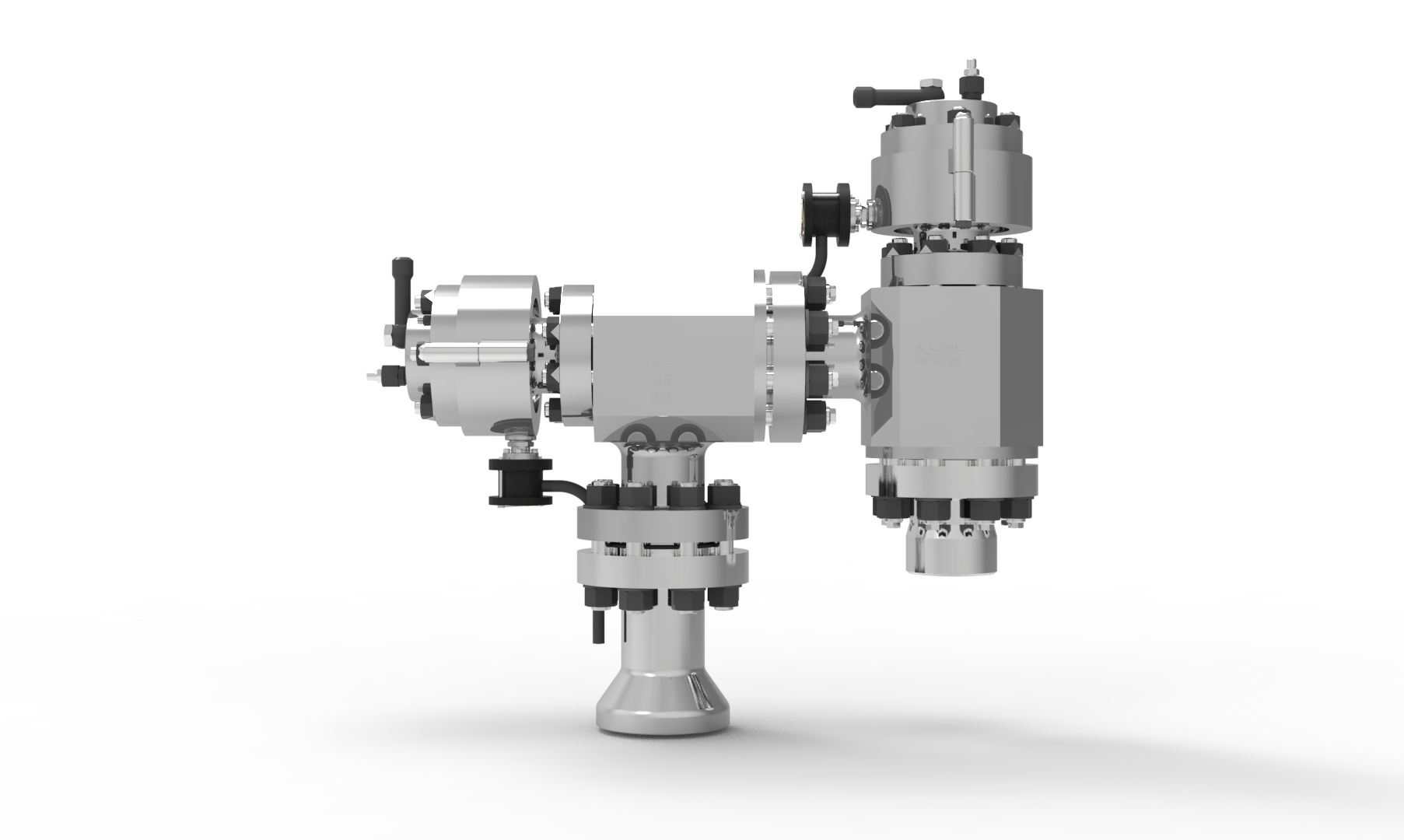

A Double Block & Bleed valve can perform the tasks of three separate valves. It would replace two separate isolations valves and one drain valve. This results in huge space savings and a sizeable weight reduction, which are positive benefits for FPSO’s and oil platforms. Double Block & Bleed valves can be supplied according to API6D and API6A.

Our double block & bleed valves are available as forged or cast valves featuring exotic material options with short delivery times.

Design

- Floating or Trunnion Mounted

- Single or Double Ball

Construction

- One piece body (top, side, or end entry)

- Split body (two or three piece)

Size & bore

Forged Valves:

- ANSI 1” – 6”

- DN 25 to DN 100

Cast Valves:

- ANSI 6” to 16”

- DN 10 to DN 400

Pressure range

Forged Valves:

- ANSI 125 to 4,500 lbs

- ISO PN 10 to PN 640

Cast Valves:

- ANSI 125 to 2,500 lbs

- ISO PN 10 to PN 400

End connections

- Flanged

- BW

- SW

- THR

- HUB

- PE

Operated

- Lever

- Gear

- Bare Stem

- Actuator

Available Materials

- Duplex

- Super Duplex

- Stainless Steel

- Carbon Steel

- Alloy 600

- Alloy 625

- C 276

- Alloy 800

- Alloy 825

- Titanium

- Zirconium

Seats

- Soft or metal seated

Seat materials

- Graphite

- Devlon

- TFM

- PTFE

- PEEK

- POM

- PCTFE

Size DN

- DN 6 – DN 400

Pressure PN

- PN 10 – PN 400

Hard facing

- Various hard facing on ball and seats

Options

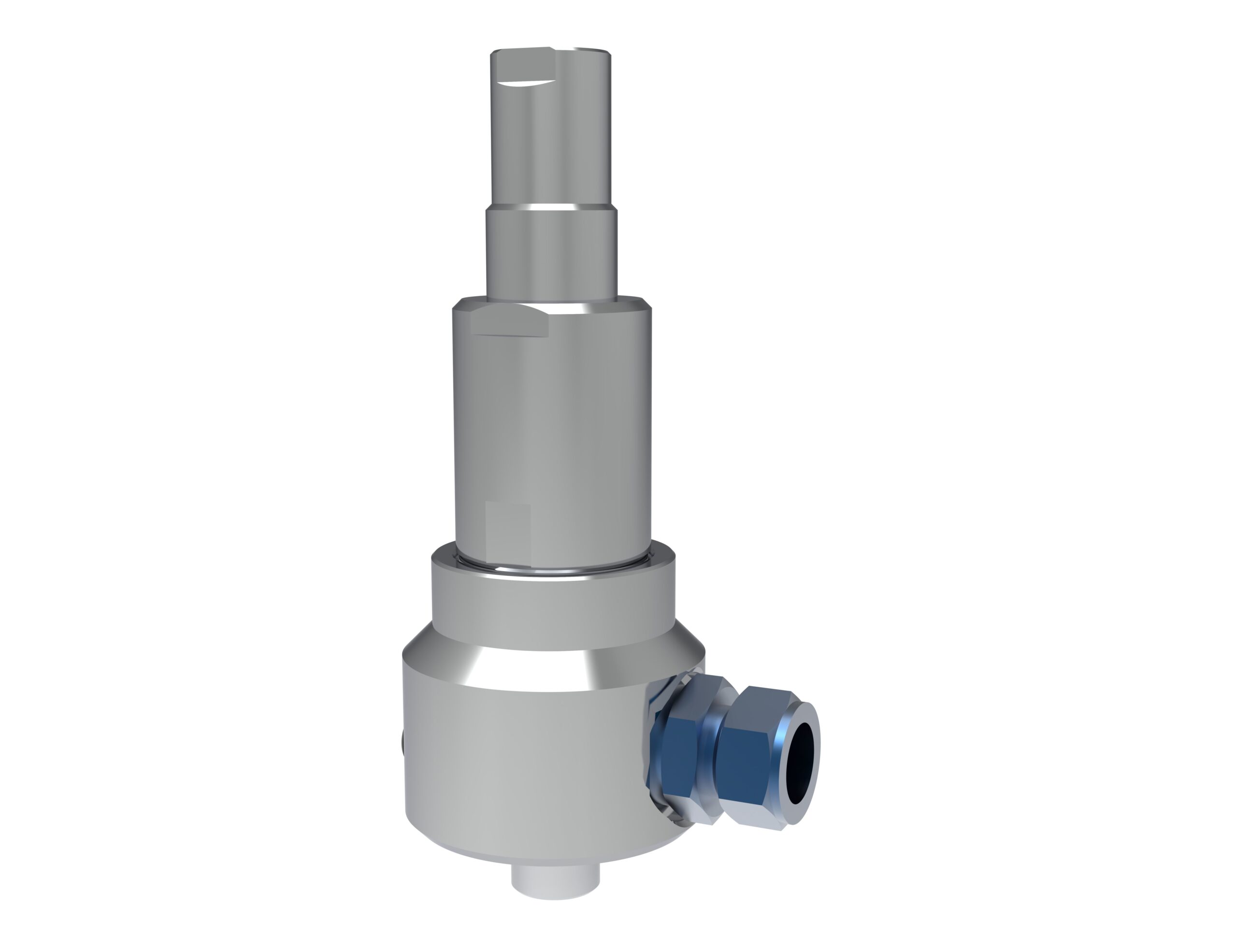

- Extended Stem

- Extended Bonnet

- Single or Double Piston

Design & Testing

All available international standards according to API, EN, ISO.