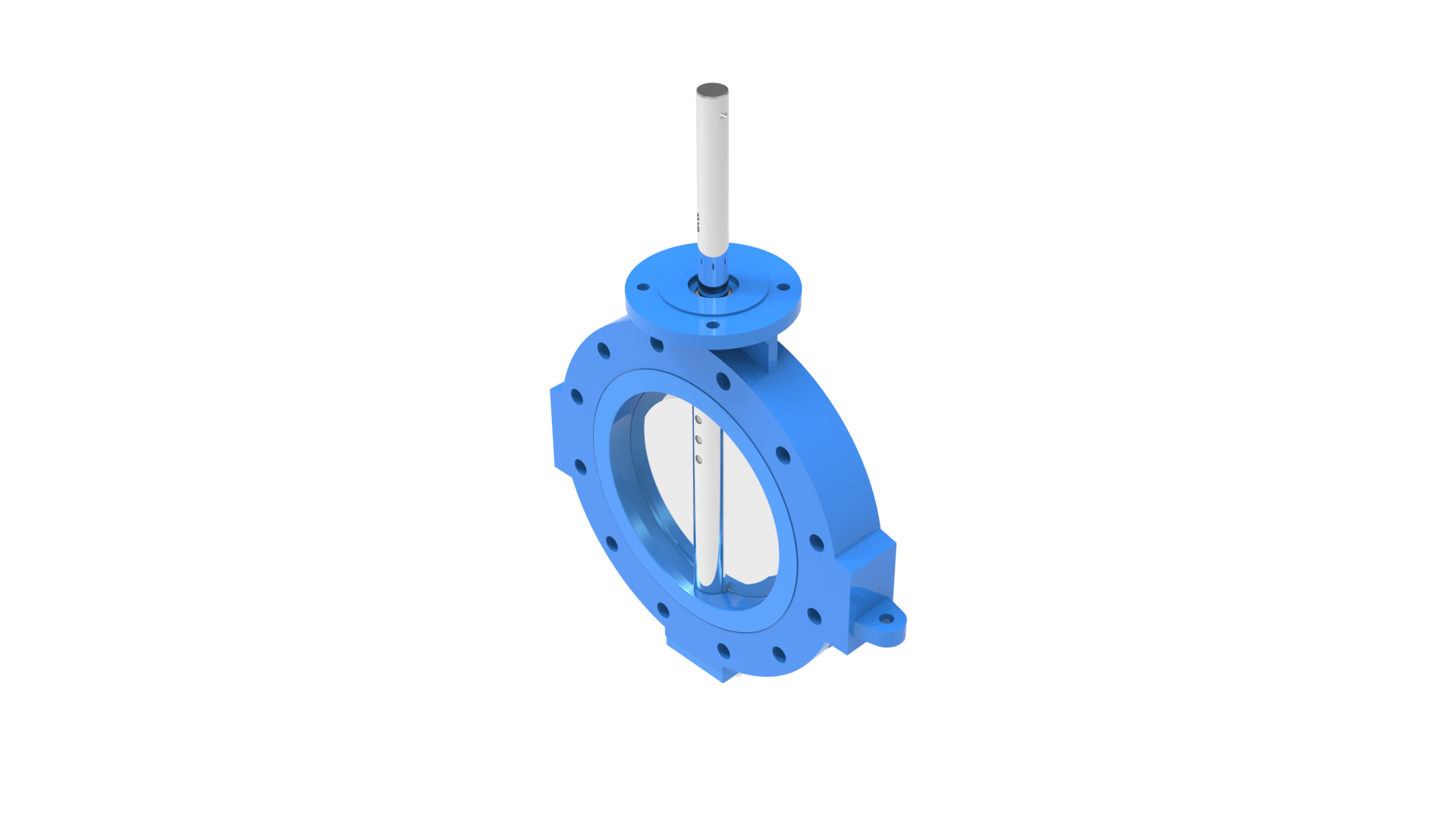

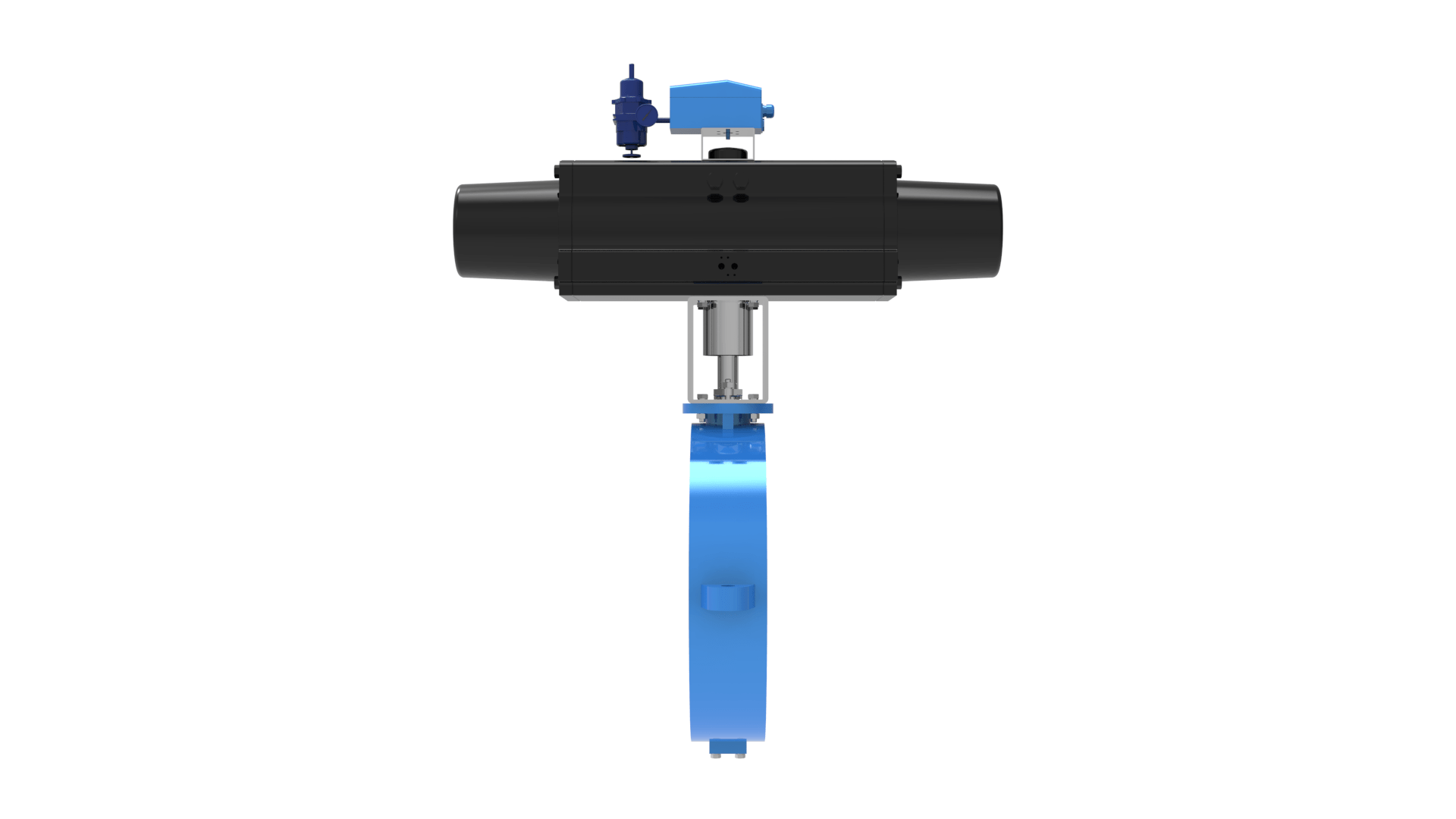

Batley Valve®

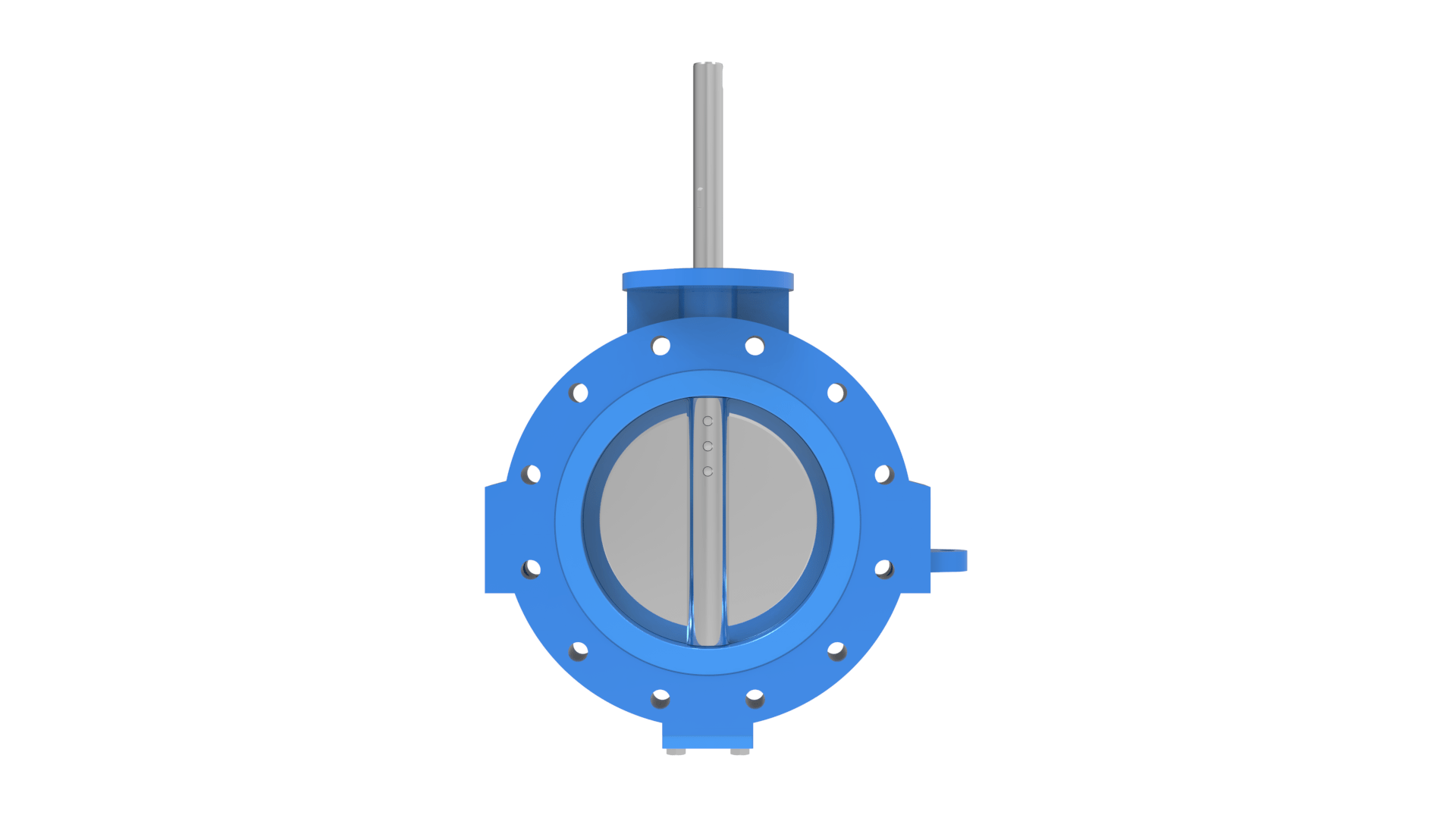

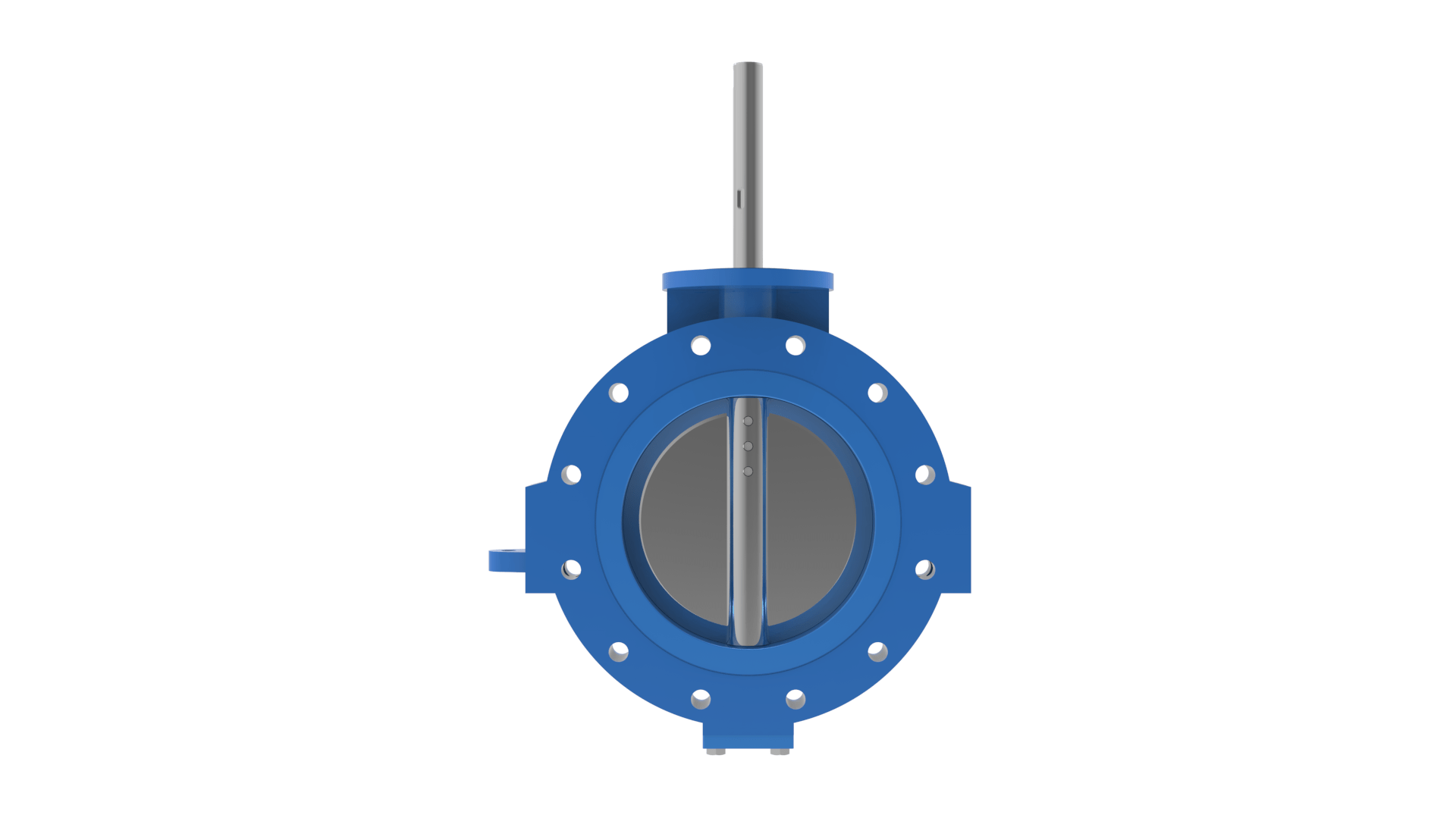

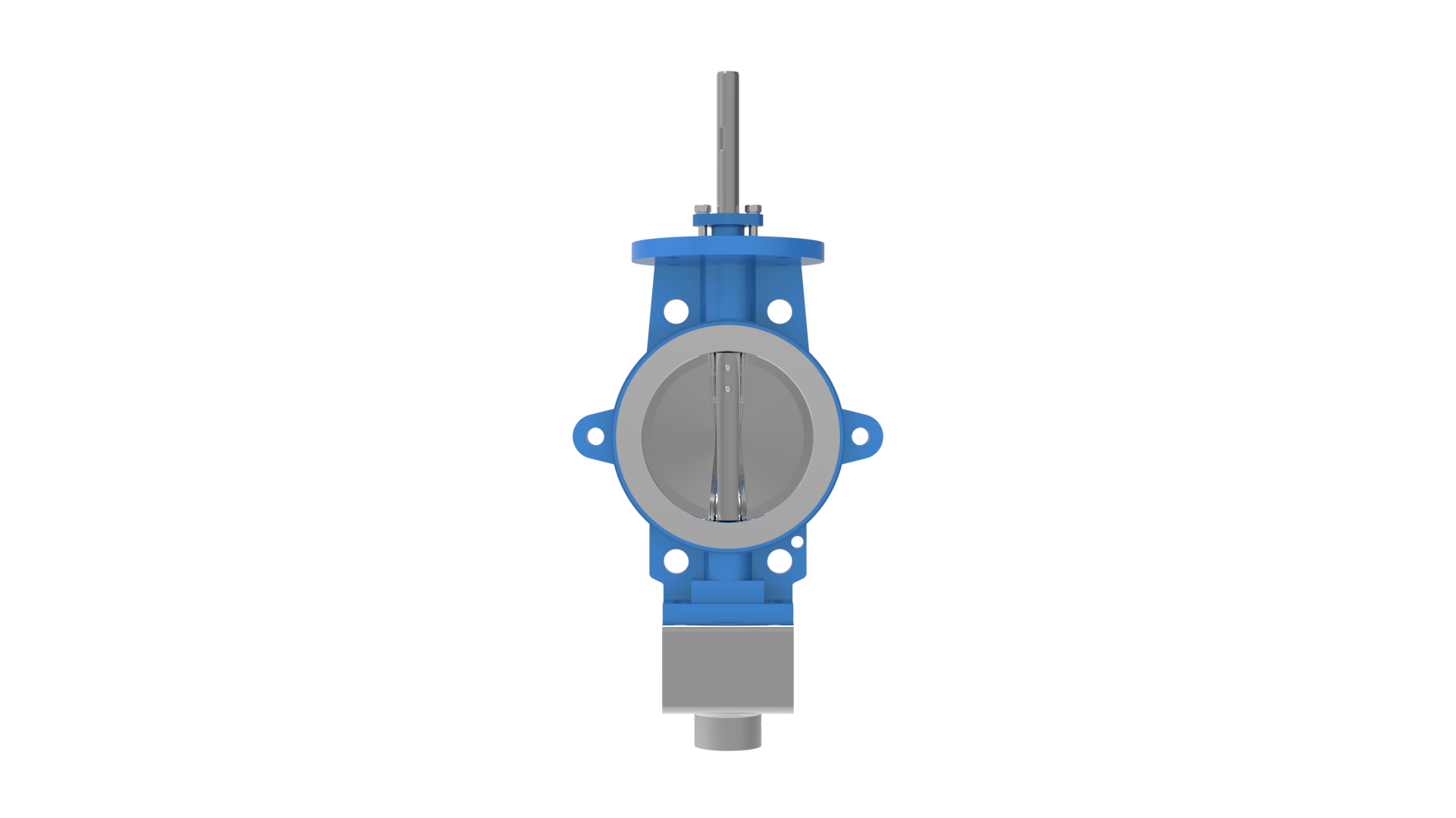

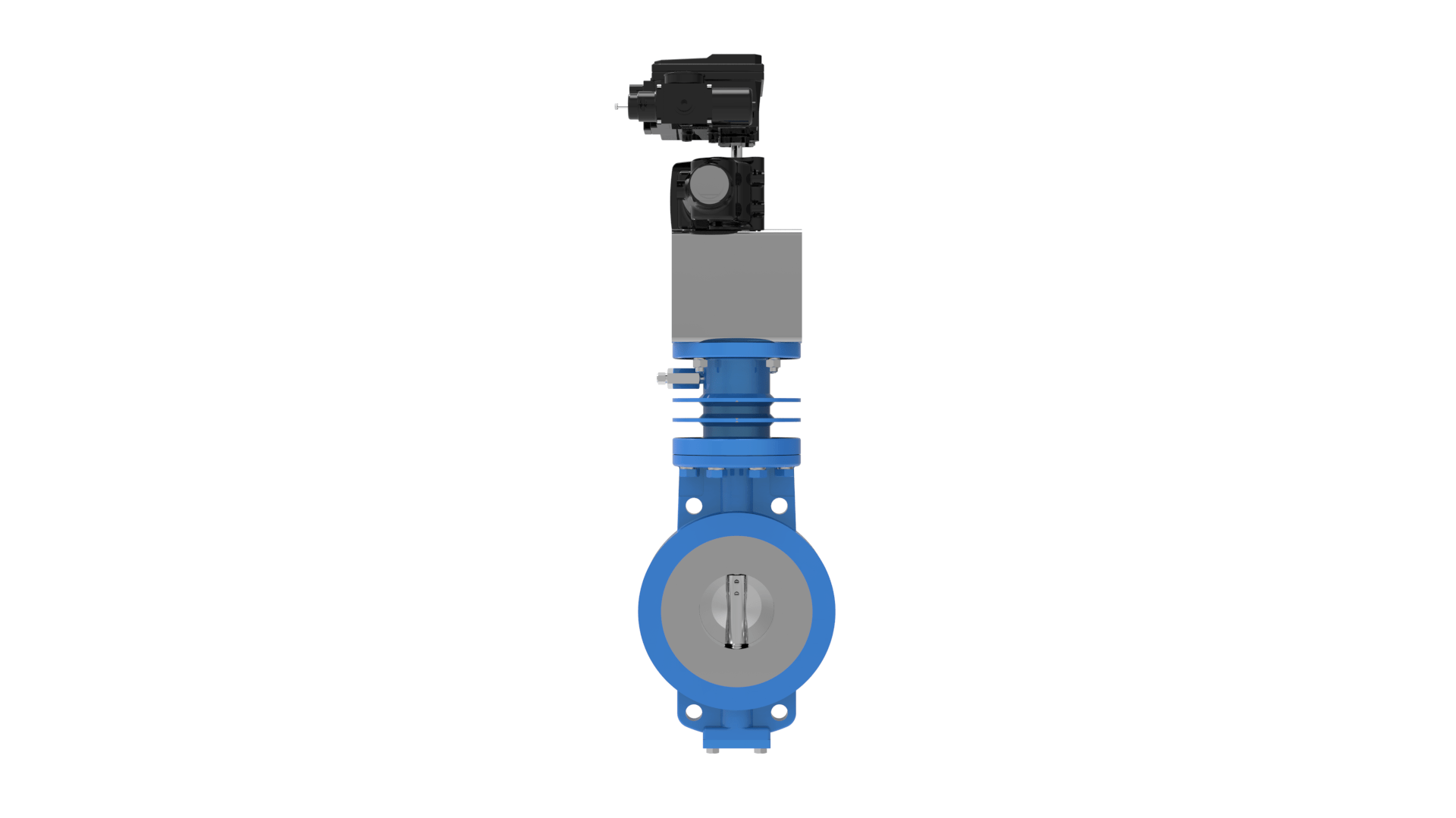

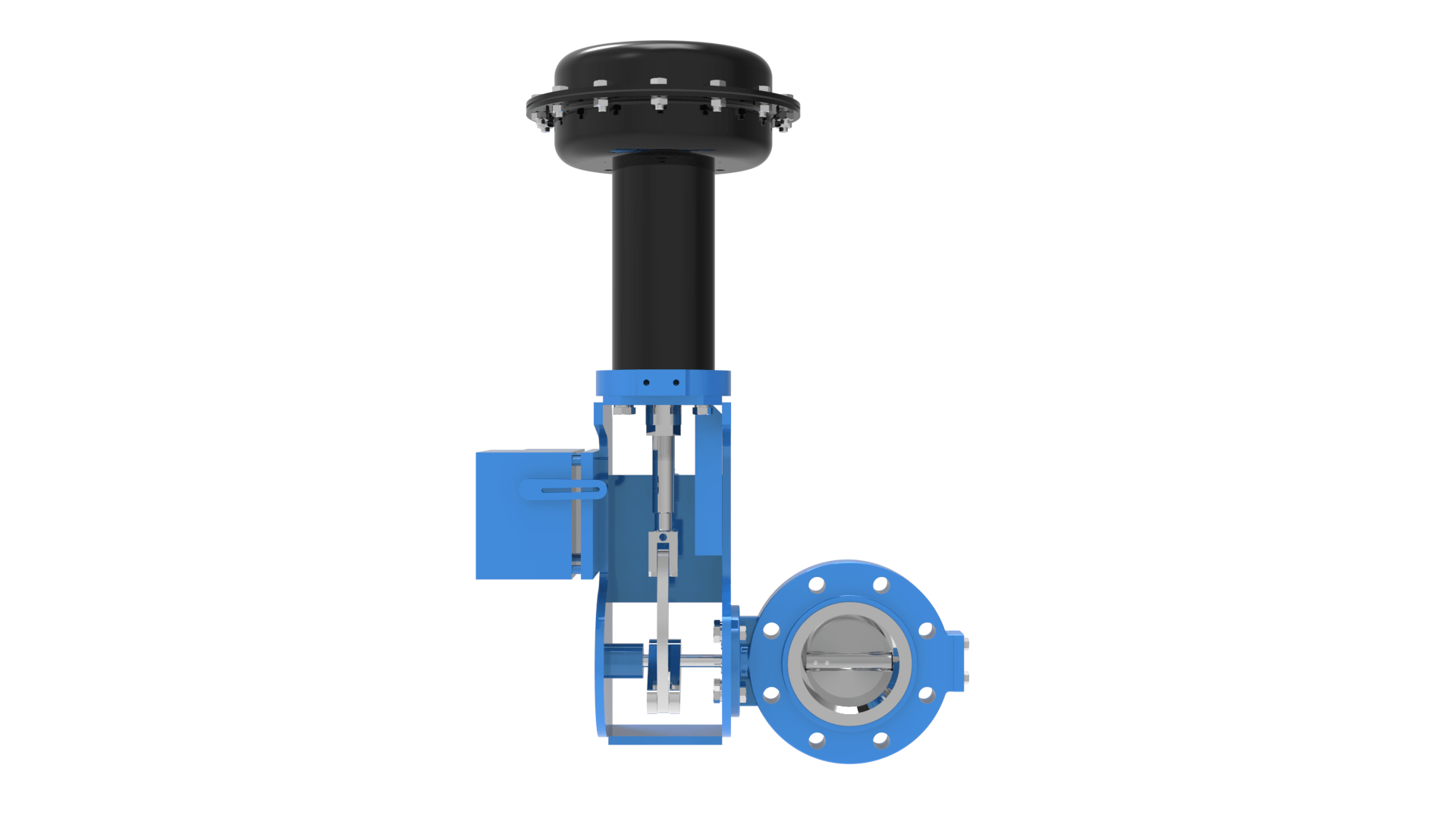

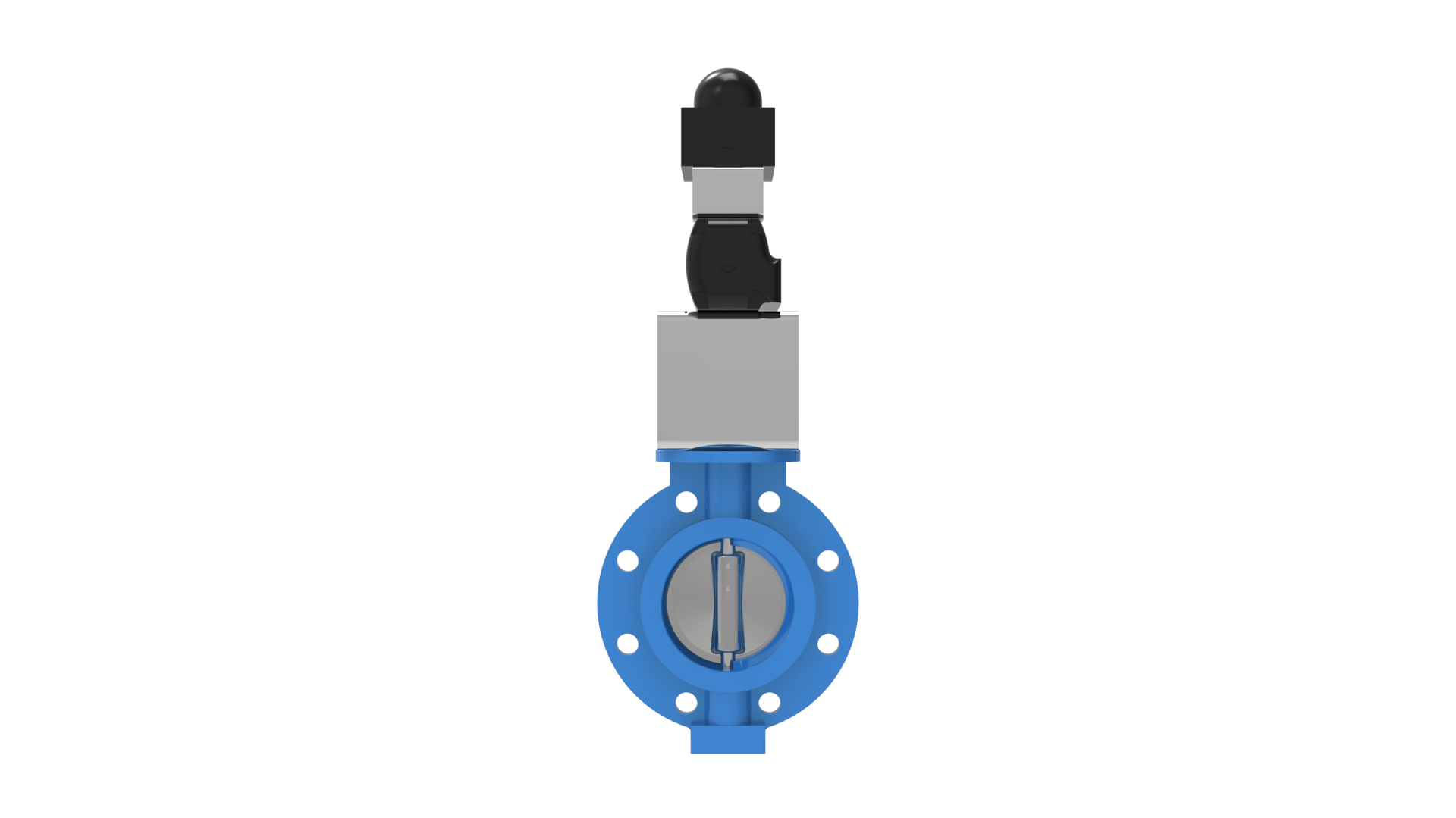

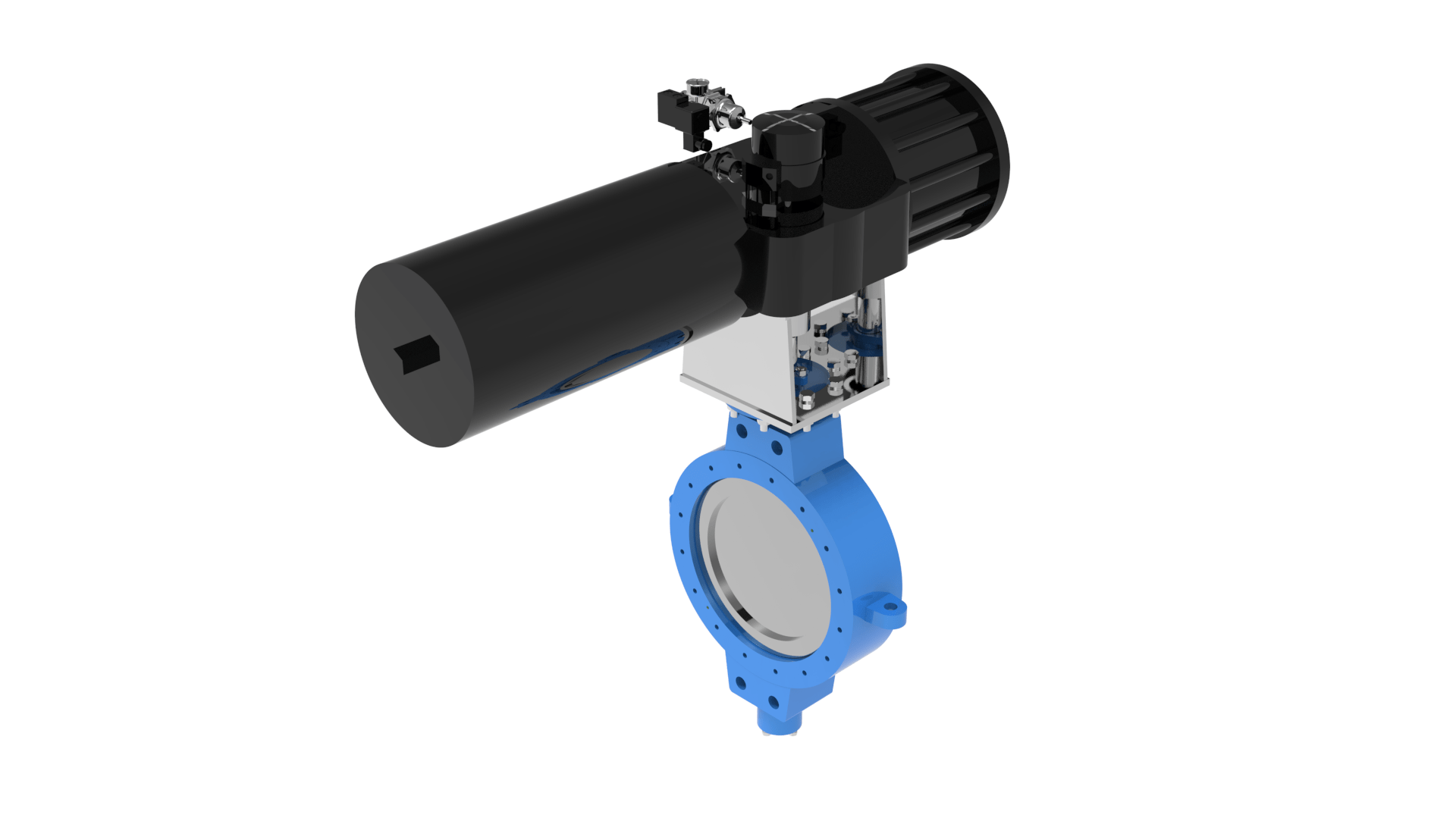

BV 18000 PTFE Lined Batseal

The Batley Valve® Batseal valve design incorporates PTFE to obtain maximum corrosion resistance for both shut off and control of line fluids.

This valve is bubble tight shut-off up to 10 bars depending upon operating temperature. Disk and spindle normally manufactured as a one piece unit.

Lining moulded teflon FEP or virgin PTFE liner protects the body from the line fluid. Resilient silicone rubber backup strips between body and lining ensure positive contact with disk at all times.

KEY FEATURES/BENEFITS

- Maximum corrosion resistance for control and isolation service

- Use of PTFE(FEP) for body lining and Vane/Spindle coating negates the need for costly corrosion resistant alloys

- Bubble tight shut-off up to 10 Bars Viton seal is used to prevent ingress of dirt or corrosive gases from the atmosphere and acts as a secondary gland

- Self lubricated PTFE faced Glacier Du Bearings combines low friction with high load bearings properties

- Resilient silicone rubber back up strips between body and lining ensure positive contact with disk at all time

- A Stainless Steel Tapered plug backed up by a resilient silicone rubber ring ensures positive contact and sealing between lining, disc and spindle

CAPACITY

- Up to 25150

MATERIALS

- Carbon Steel

- Stainless Steel

- Duplex

- Super Duplex

- Hastalloy

- Inconel

- Monel

- Titanium

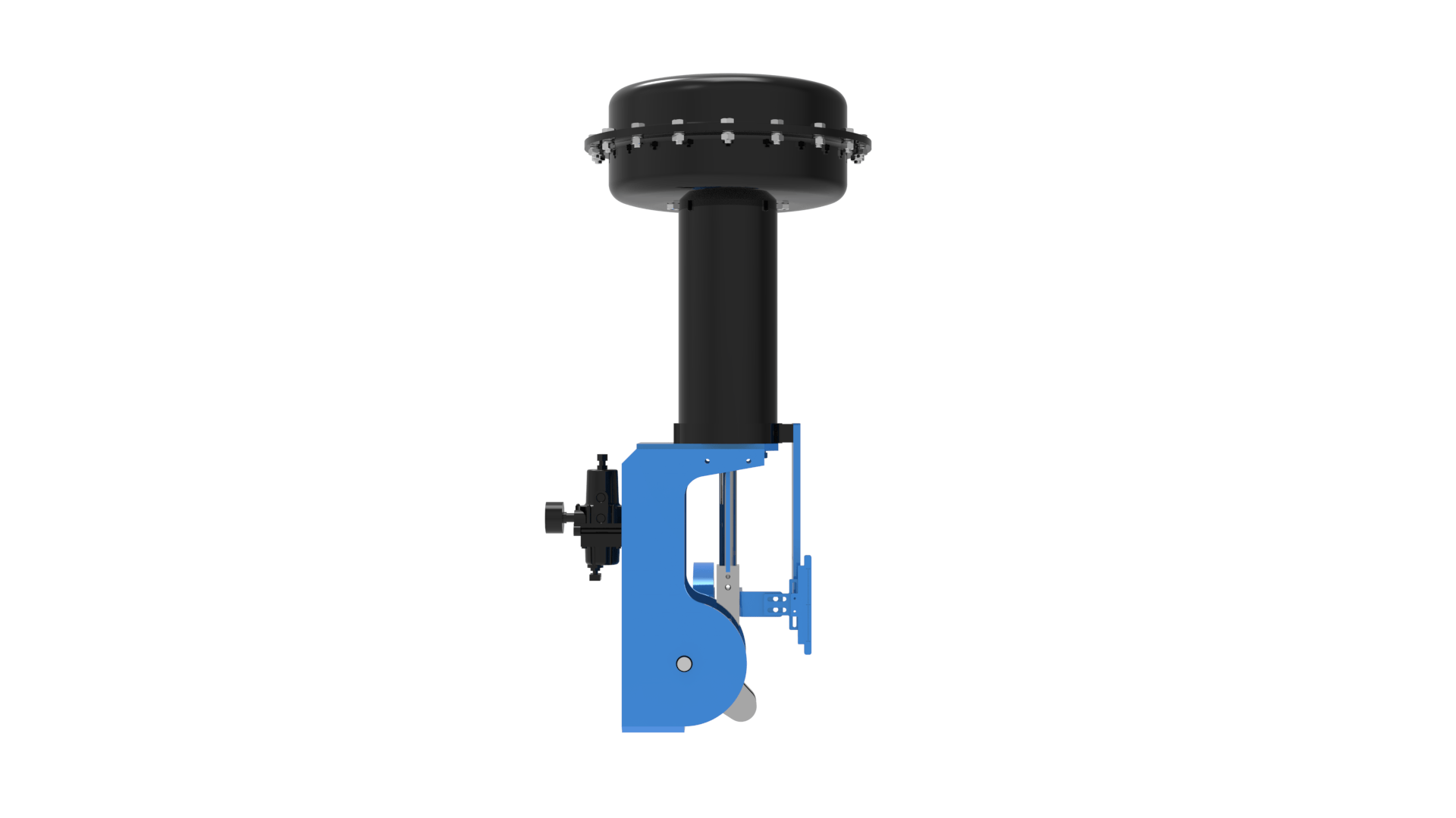

APPLICATIONS

- Desalination and Water Treatment Plants

- Chemicals & Corrosive services

DESIGN STANDARDS

- ANSI B16.34

DESIGN RATINGS

- ASME 150

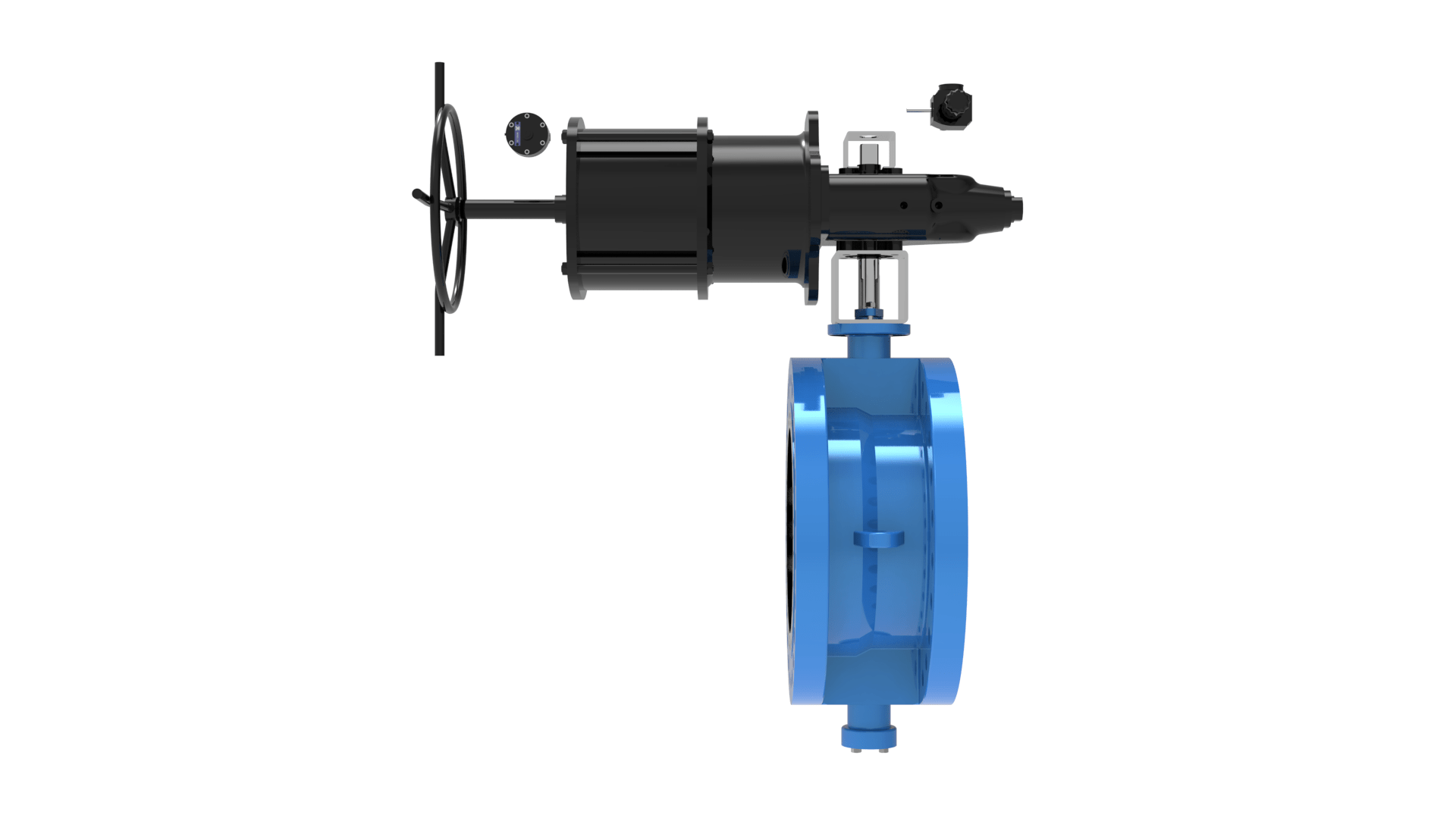

SIZE RANGE/ DIMENSIONS

- 100 to 600mm (4″” to 24″”)

TEMPERATURE RANGE

- 0ºC up to 150ºC (32ºF to 302ºF)

TRIM MATERIALS

- 316 SS or 17-4 PH with PTFE, FEP, E-CTFE coatings.

TRIM MATERIAL UPGRADES

- SS

- Titanium

- Monel

- Hastelloy

- Duplex

- Ferralium

- Alloy 20