Red Point®

Gate Valves With Extended Bonnet

An extended bonnet is used for both low temperature and high temperature applications. The extended bonnet has the function of protecting the stuffing box and prevent leakage of the stempacking.

Low temperature applications and types of medium examples include: LNG applications, ethylene liquid, oxygen, liquid hydrogen, and liquefied natural gas.

High temperature applications and types of medium examples include: steam applications, sour service.

Our gate valves with extended bonnet are available as forged or cast valves featuring exotic material options with short delivery times.

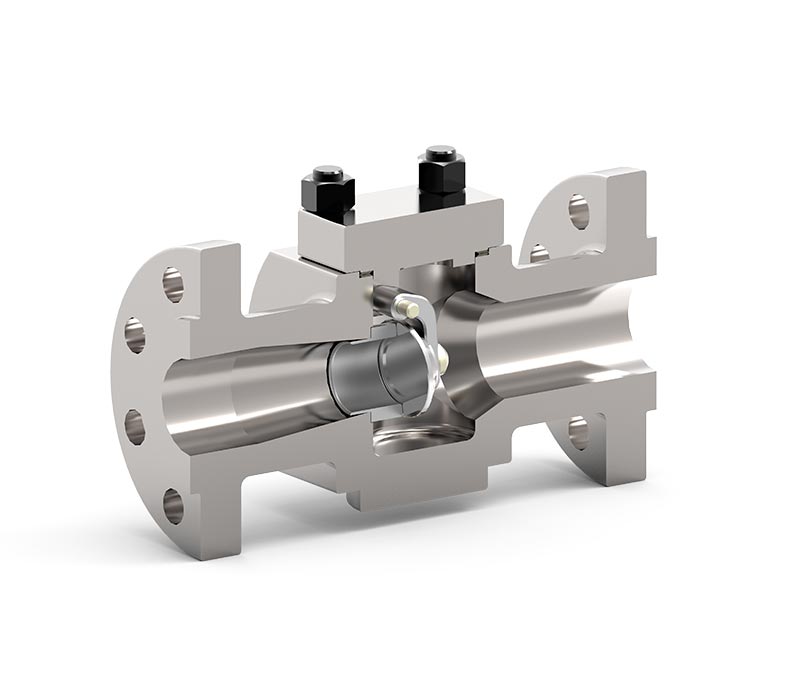

Type of wedge

- Flexible

- Solid

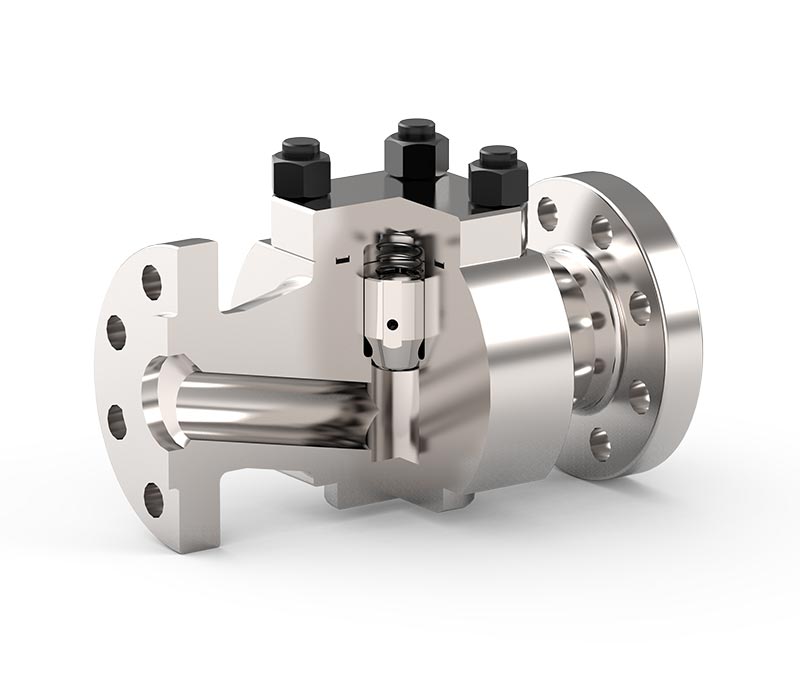

Construction

- Bolted

- Welded

- Extended

End connections

- Flanged

- BW

- SW

- THR

- HUB

- PE

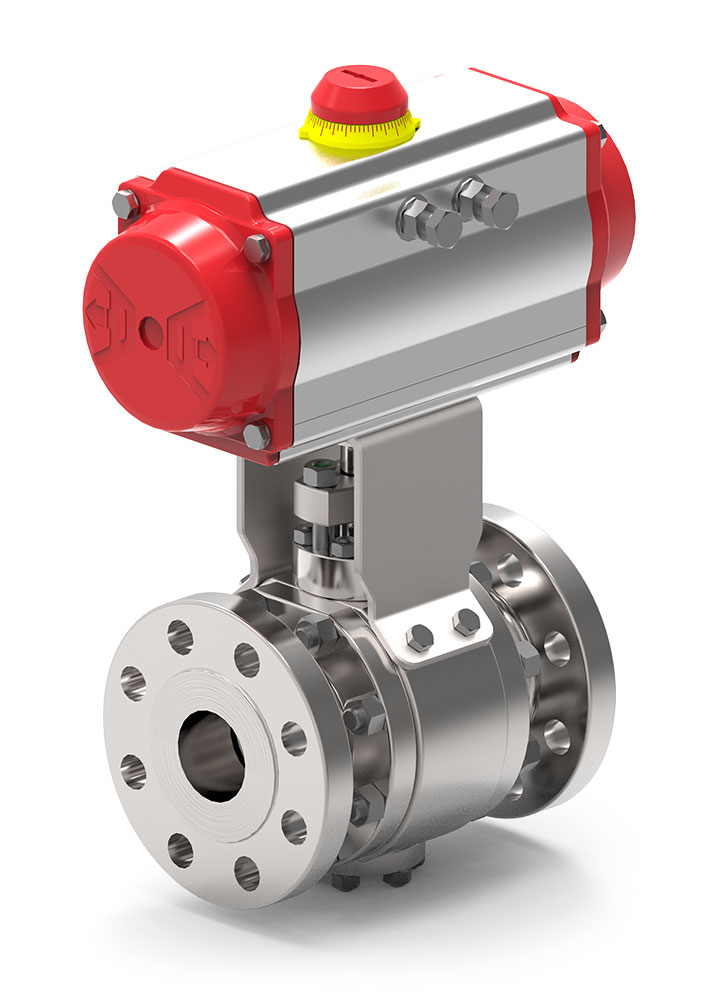

Operated

- Handwheel

- Gear

- Bare Stem

- Actuator

Options

- Extended Bonnet

- Bellow Sealed

- Heating Jacket

- DBB Configuration

Bellow seal materials

- 304

- 321

- 316Ti

- Alloy 625

- C276

Design & testing

- All available international standards according to API, EN, ISO

- Thoroughly degreased and cleaned for O2 services

Size & bore

Forged Valves:

- ANSI 1” – 6”

- DN 25 to DN 100

Cast Valves:

- ANSI 6” to 16”

- DN 10 to DN 400

Pressure range

Forged Valves:

- ANSI 125 to 4,500 lbs

- ISO PN 10 to PN 640

Cast Valves:

- ANSI 125 to 2,500 lbs

- ISO PN 10 to PN 400