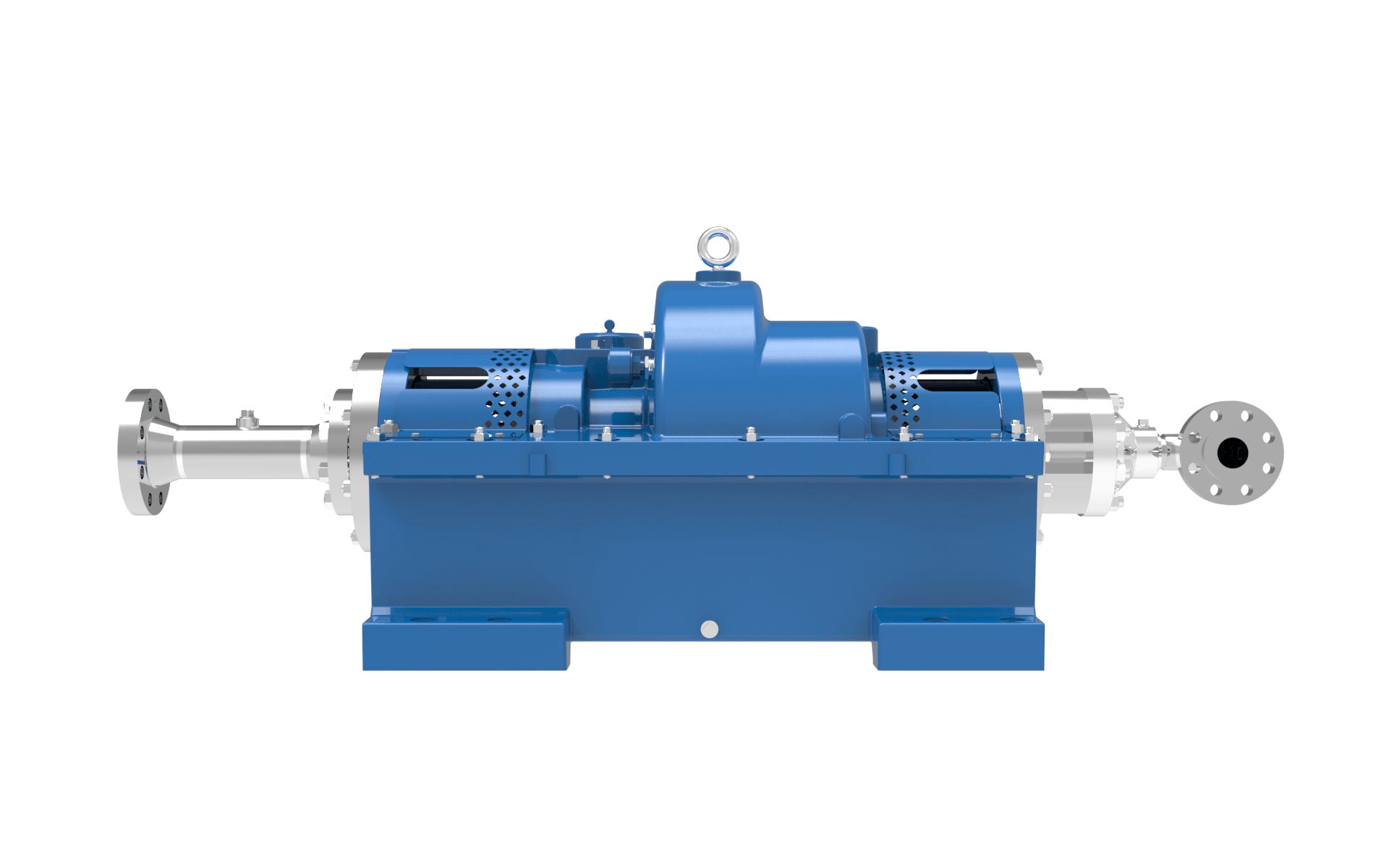

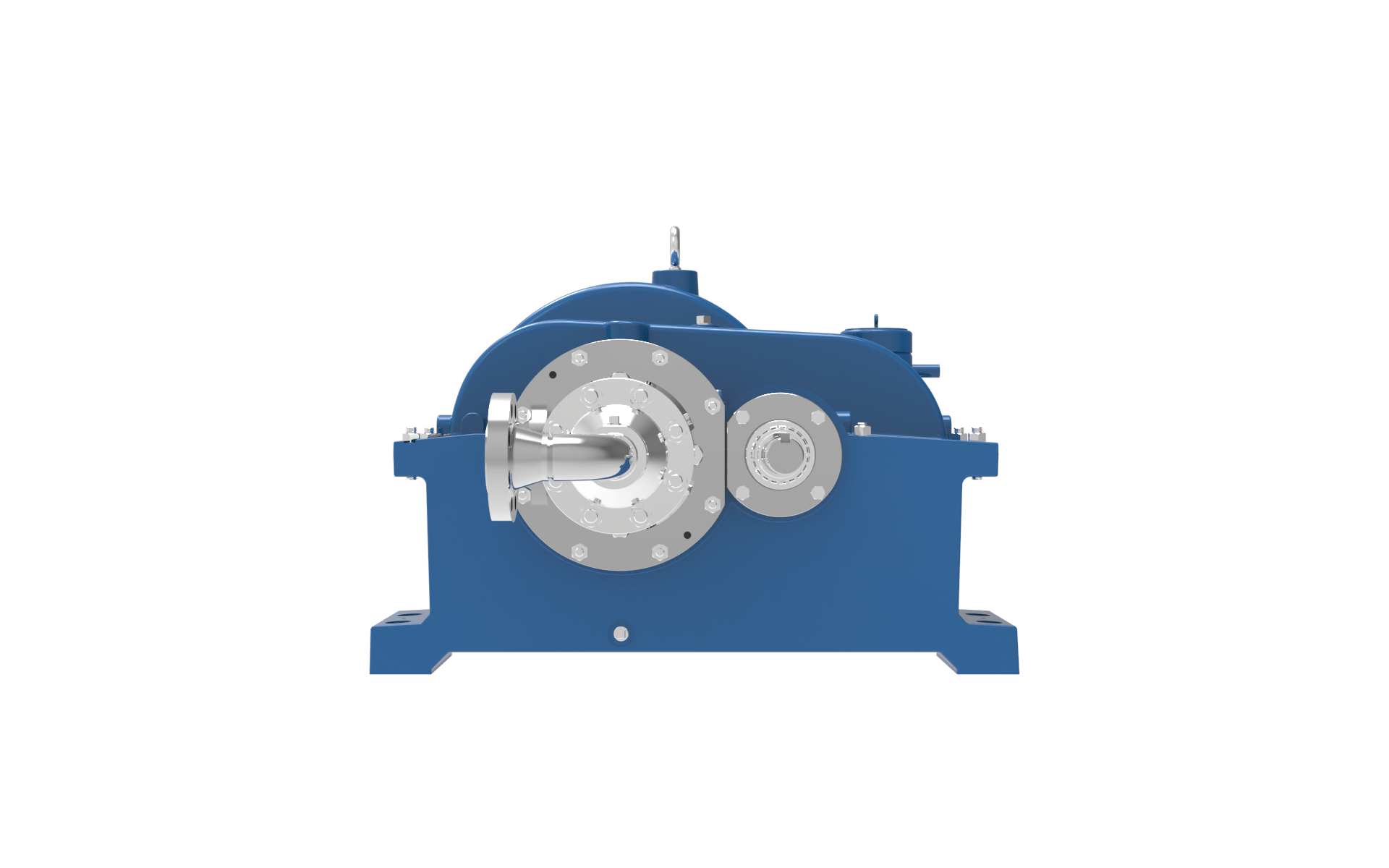

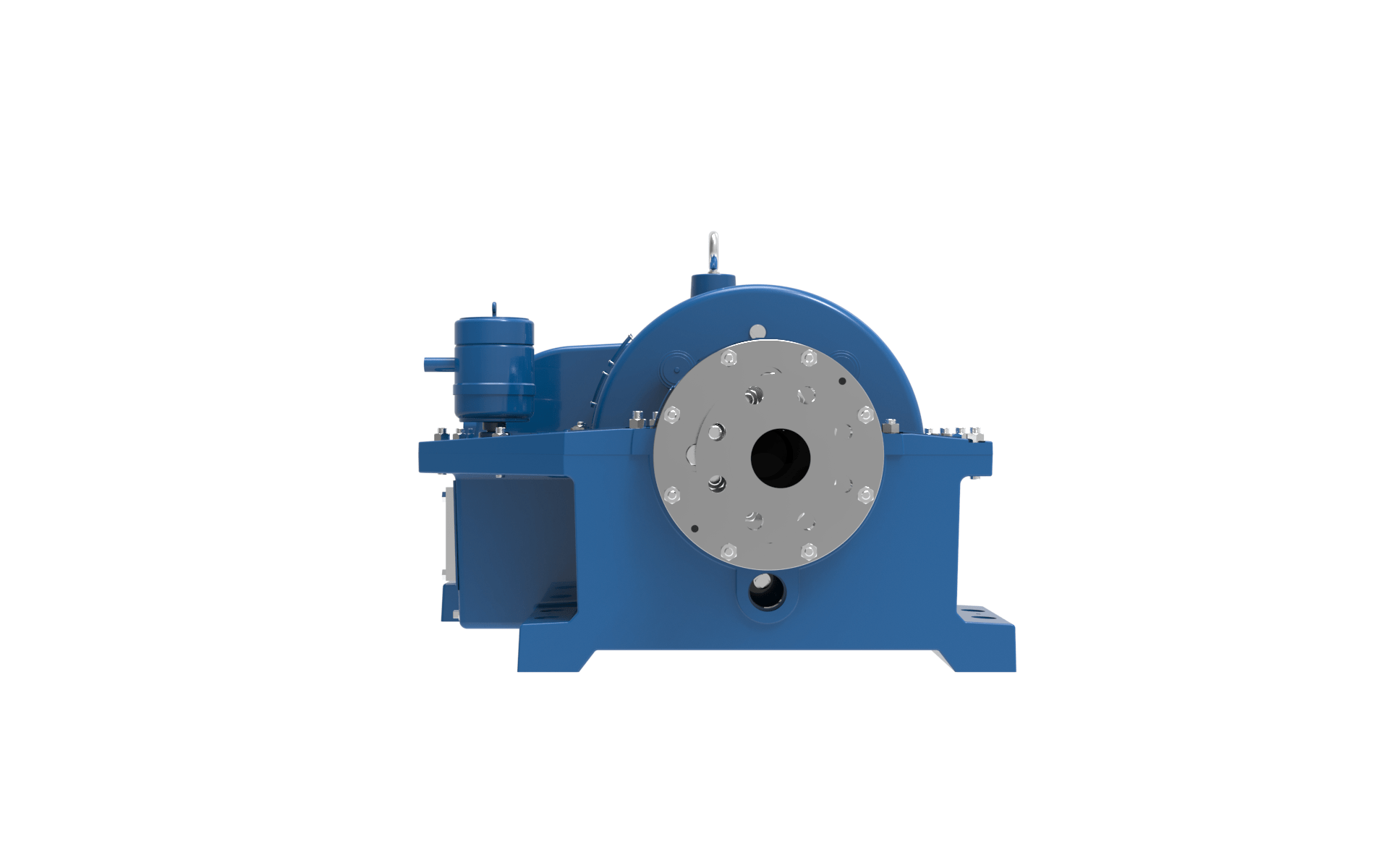

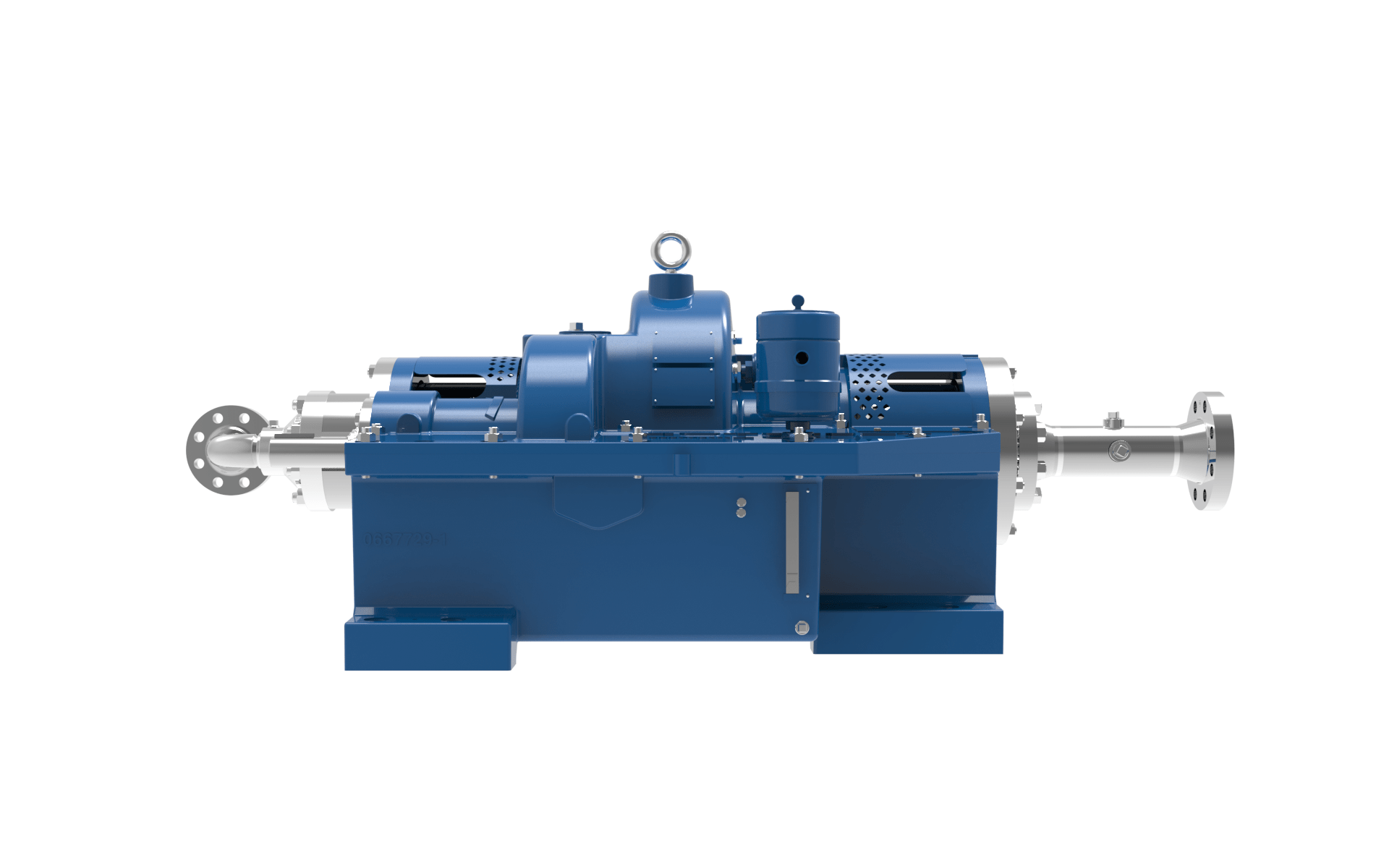

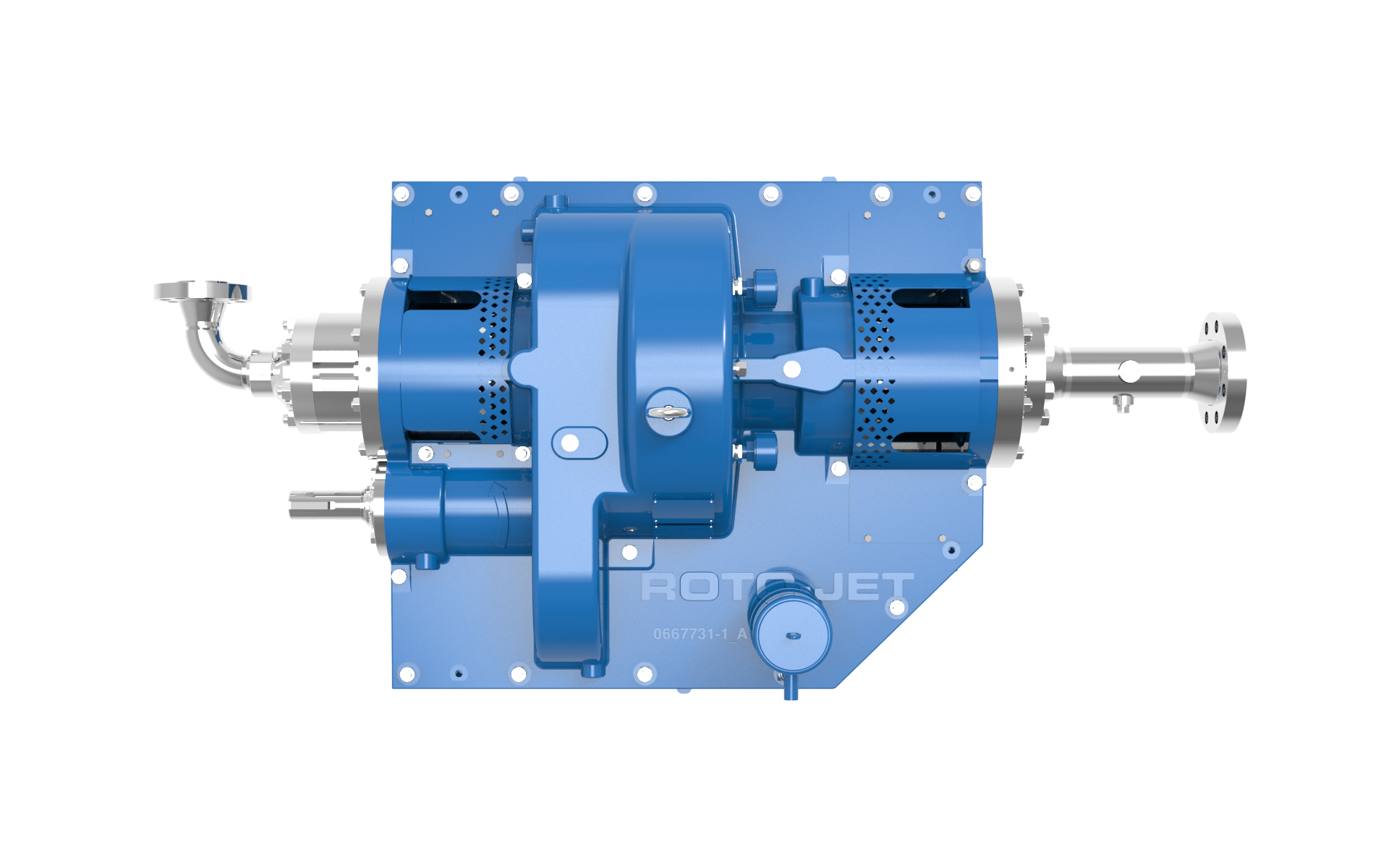

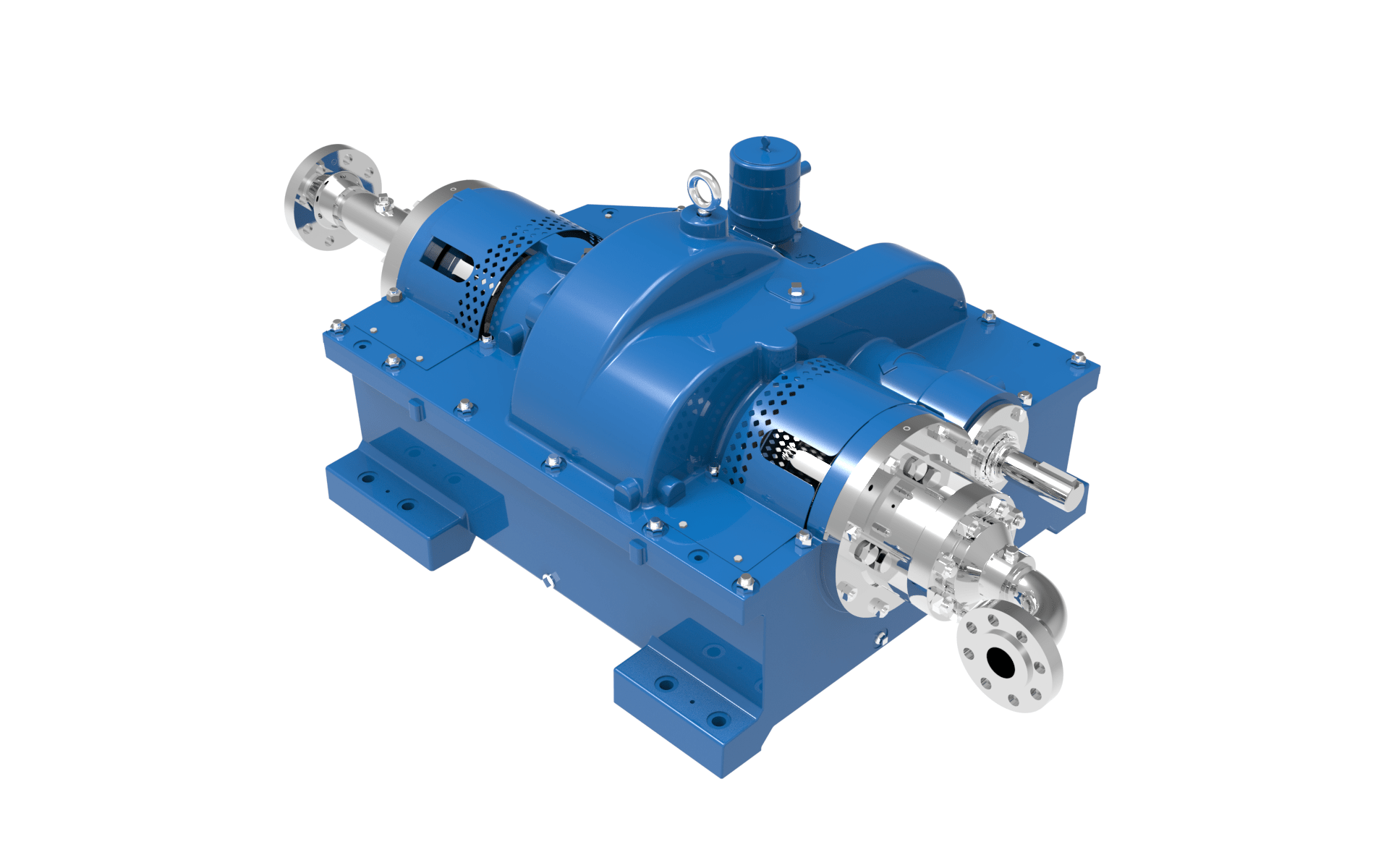

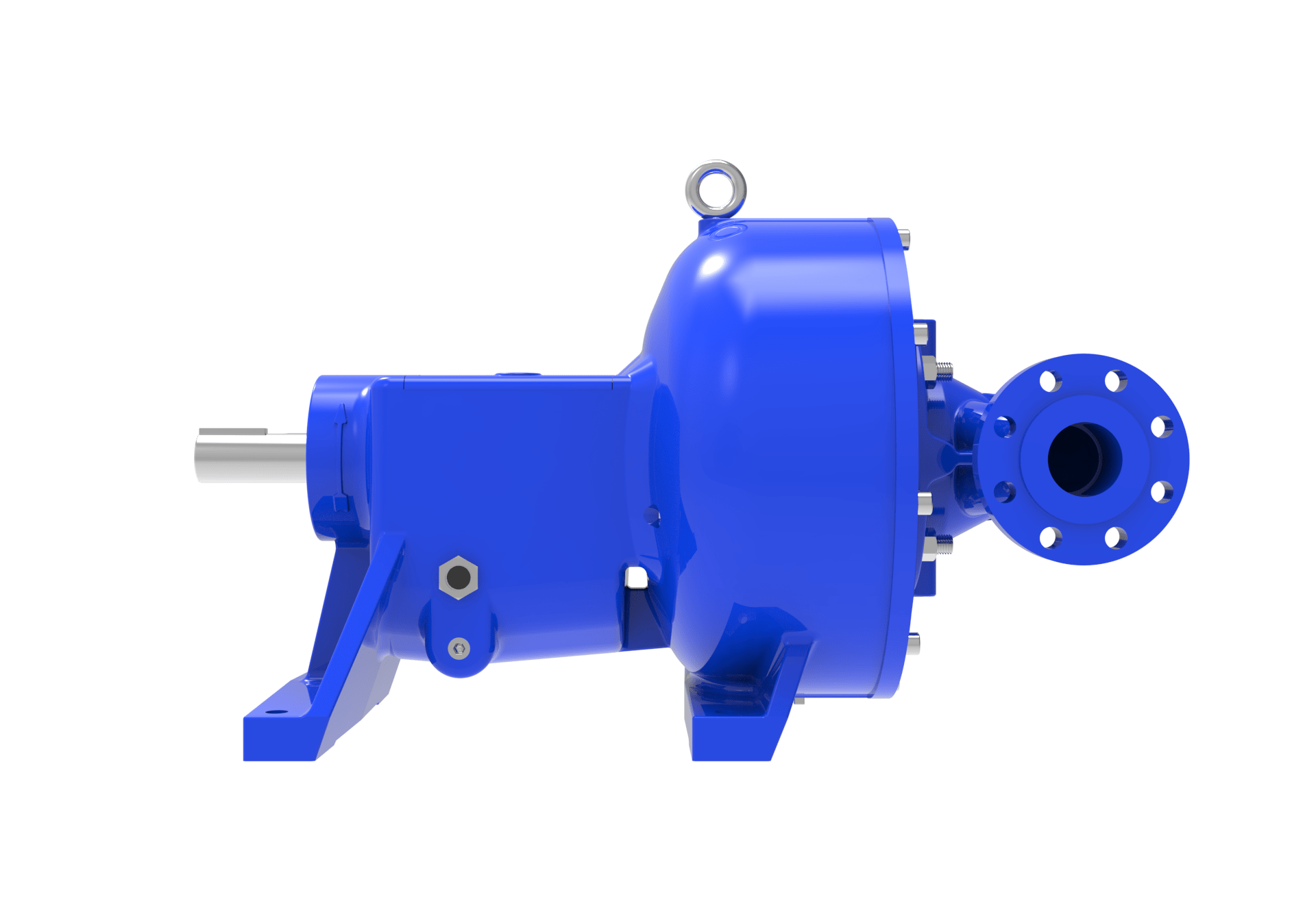

Roto-Jet®

RO-FT API 610

The Roto-Jet® RO-FT API 610 pump was designed specifically for demanding low-flow, high-head services, and fully meets the requirements of API 610. The RO-FT between-bearing configuration provides a reliable, robust, and easy to maintain pump for the midstream and downstream refining, petrochemical, and chemical processing industries.

The operating characteristics of the Roto-Jet® RO-FT API 610 pump are similar to a conventional centrifugal pump. Energy is added to the fluid via the rotor, and the stationary Pitot tube converts the fluid velocity energy into static pressure.

In addition, the Roto-Jet® RO-FT API 610 pump is specifically designed to achieve a broad operating range. These attributes result in improved mechanical seal and bearing life to maximize Mean Time Between Failure, and decrease operational and maintenance costs, which make the Roto-Jet® the most cost effective choice for low-flow, high head process applications.

KEY FEATURES & BENEFITS

- API 610 11th Edition compliant

- Standard API 682 cartridge seals

- No external lube system required

- No wear rings or close running clearances

- Low NPSH3 without the use of an inducer

- Robust design is insensitive to process upsets

- Pulsation free flow over the entire head-flow curve

- Integral gearbox is isolated from process seal leakage

- Reduced life cycle cost by optimizing hydraulic efficiency

- Process seals exposed only to suction pressure to maximize seal life

- Between bearings arrangement minimizes shaft deflection at the seals

- Bearing L10 life exceeds API 610 requirements using rolling element bearings

- Patented rotor eliminates radial and axial thrust as a function of flow rate and suction pressure

- High heads achieved in a single stage at low operating speeds compared to other low-flow

- High-head pumps

APPLICATIONS

- Caustics processing

- Amine treating

- Reflux streams

- Transfer services

- Boiler feed

- NaphthaWash water

- Reactor feed

- Condensate and well injection

- Boiler feed water

- Foul water

- Diesel

- Gasoline

- Kerosene

- Sour water

- Depropanizer

- Deethanizer

TEMPERATURE RANGE

- Up to 550ºF (290ºC)

CAPACITY – HEAD

- Up to 5,000 ft. (1,500 m) Flow: up to 450 gpm (102 m³/h)

MATERIALS – ROTOR

- Carbon Steel (A216 WCB)

- 12% CR (A487 CA6NM)

- 316 AUS (A351 CF3M)

- Duplex (A890 CD4MCu)

FLANGES

- Carbon Steel (A216 WCB)

- 316 AUS (A351 CF3M)

SHAFT ASSEMBLY

- Carbon Steel (A216 WCB)

- 316 AUS (A351 CF3M)

INPUT SHAFT

- 4140 Carbon Steel (A193)

PITOT TUBE

- 17-4-PH Stainless Steel (A564) or Inconel 718

GEAR CASE MATERIAL

- Carbon Steel (A216 WCB)