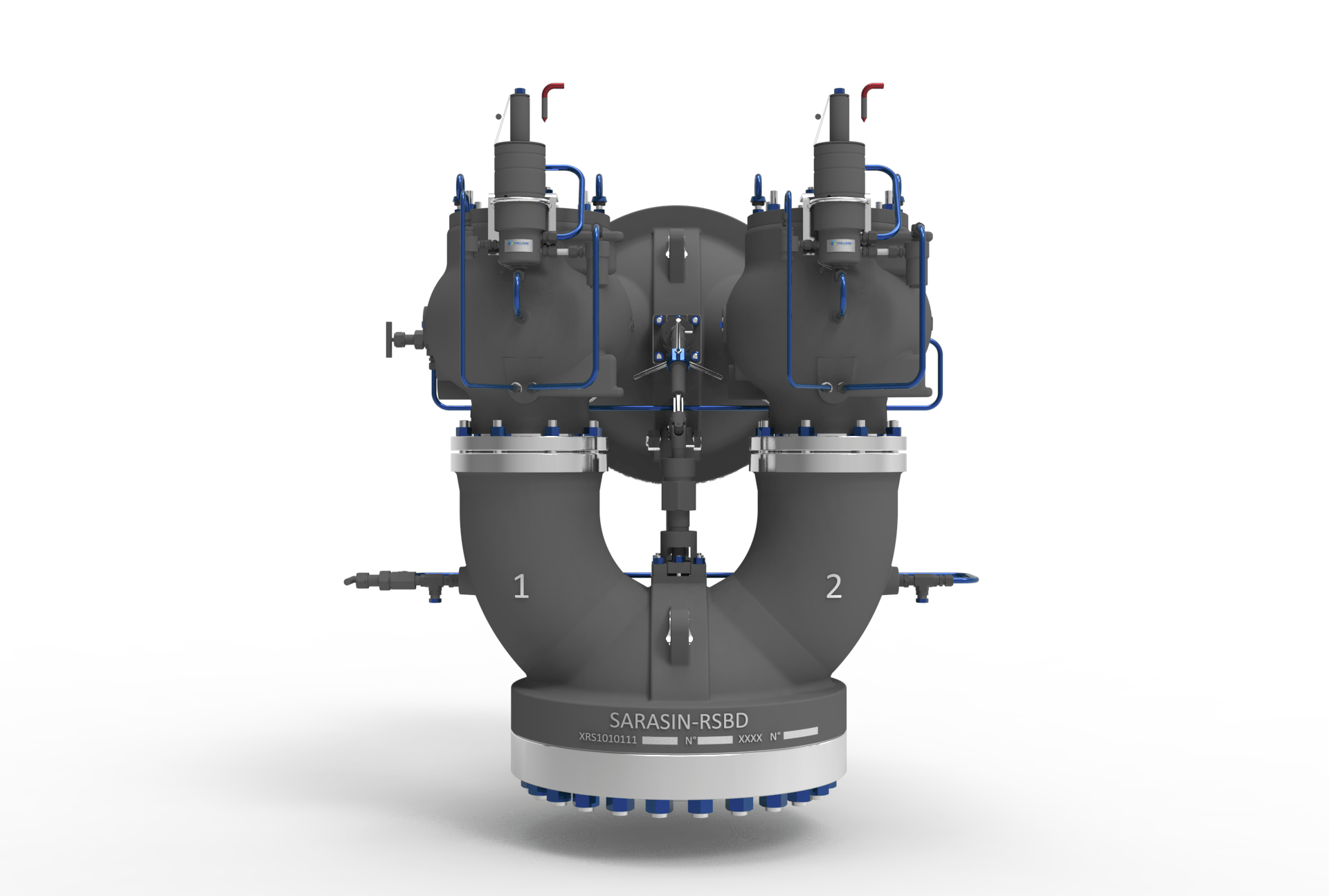

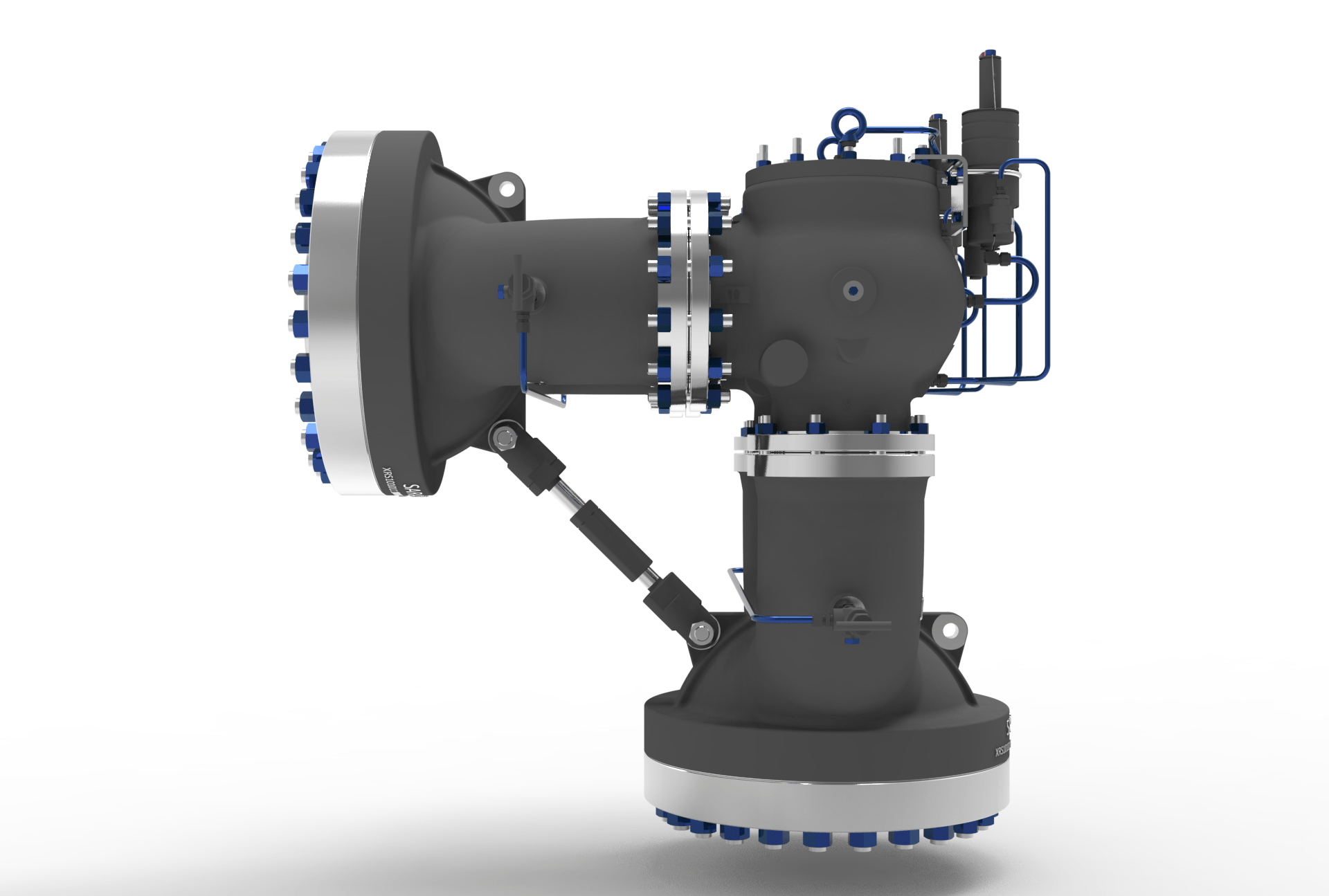

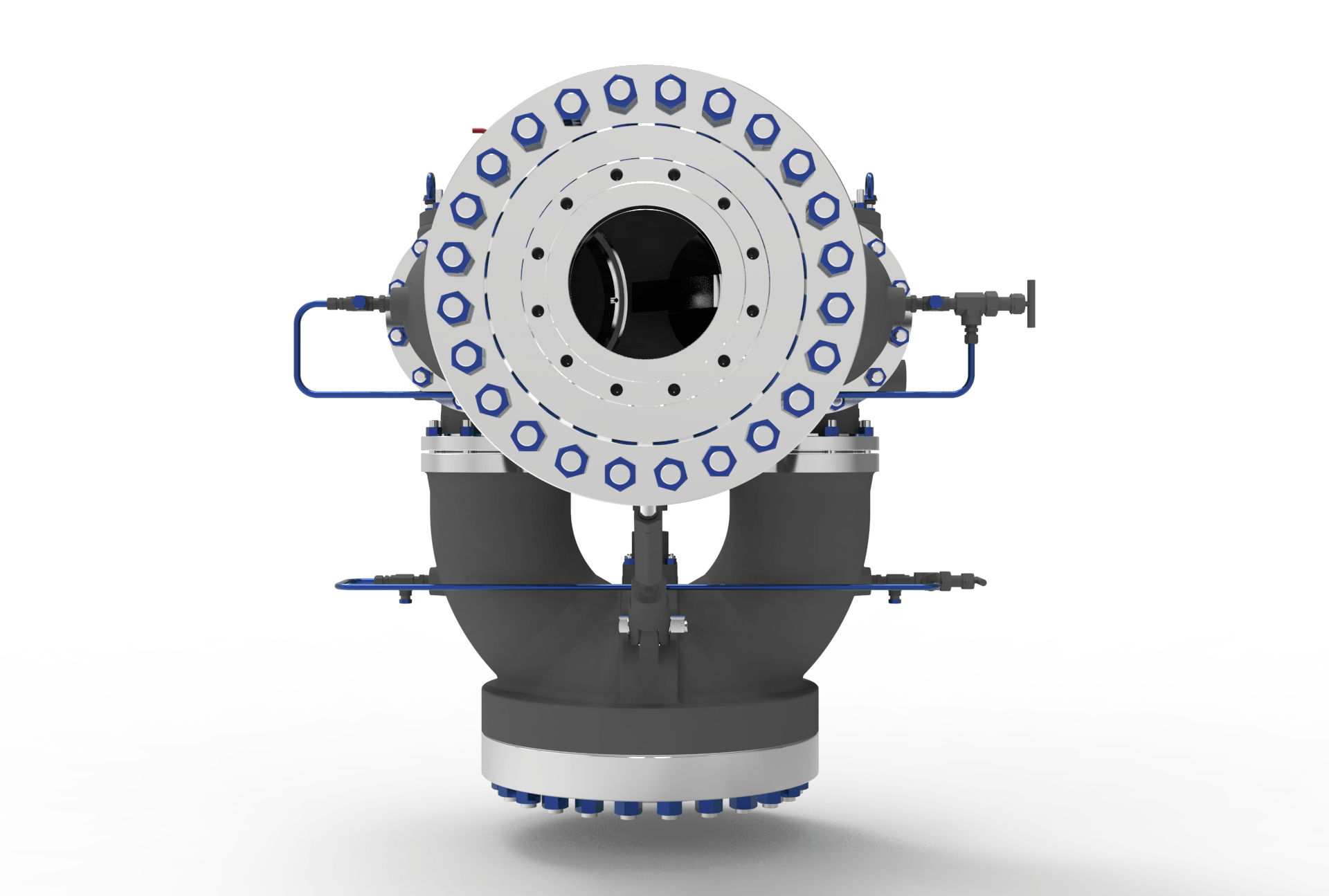

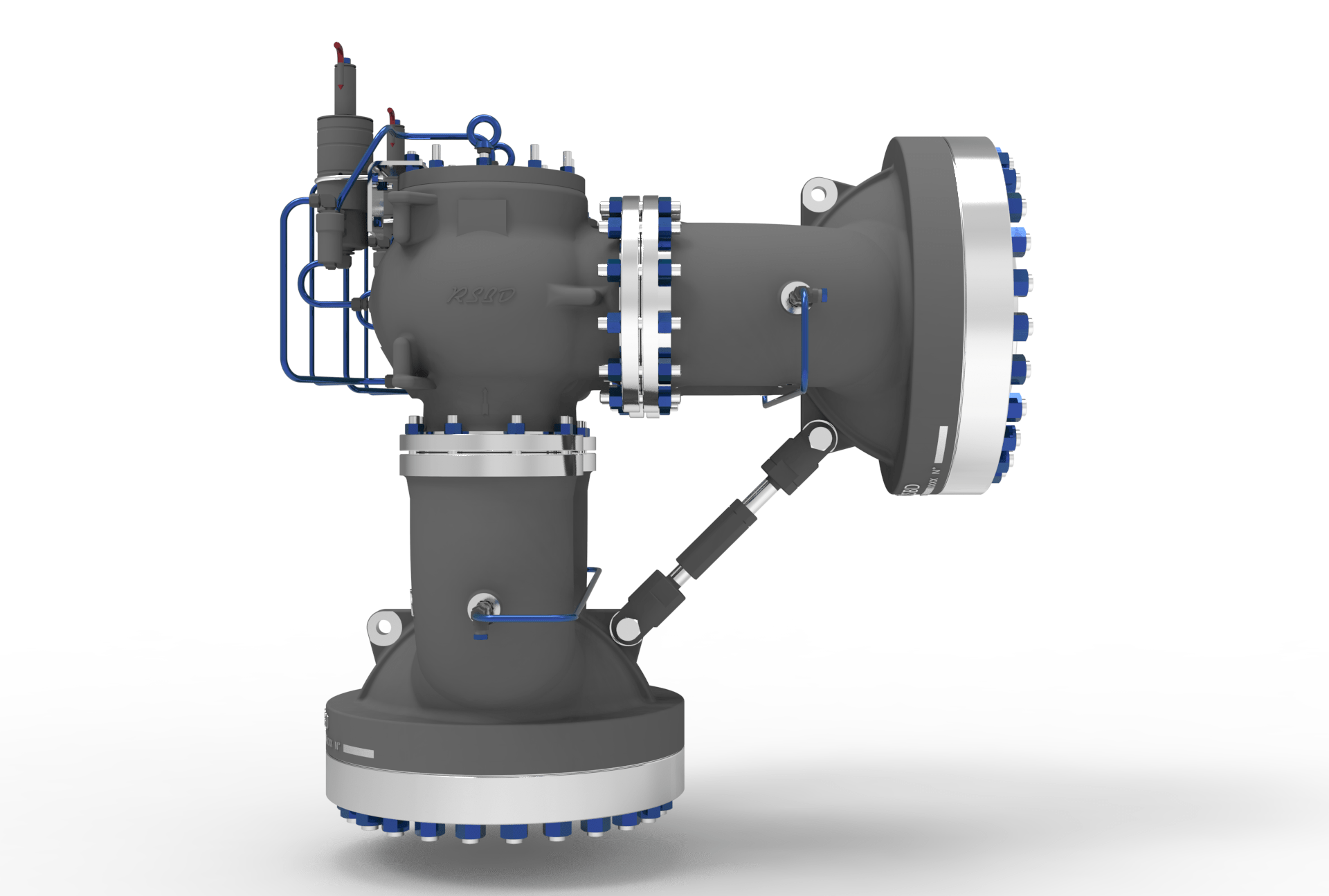

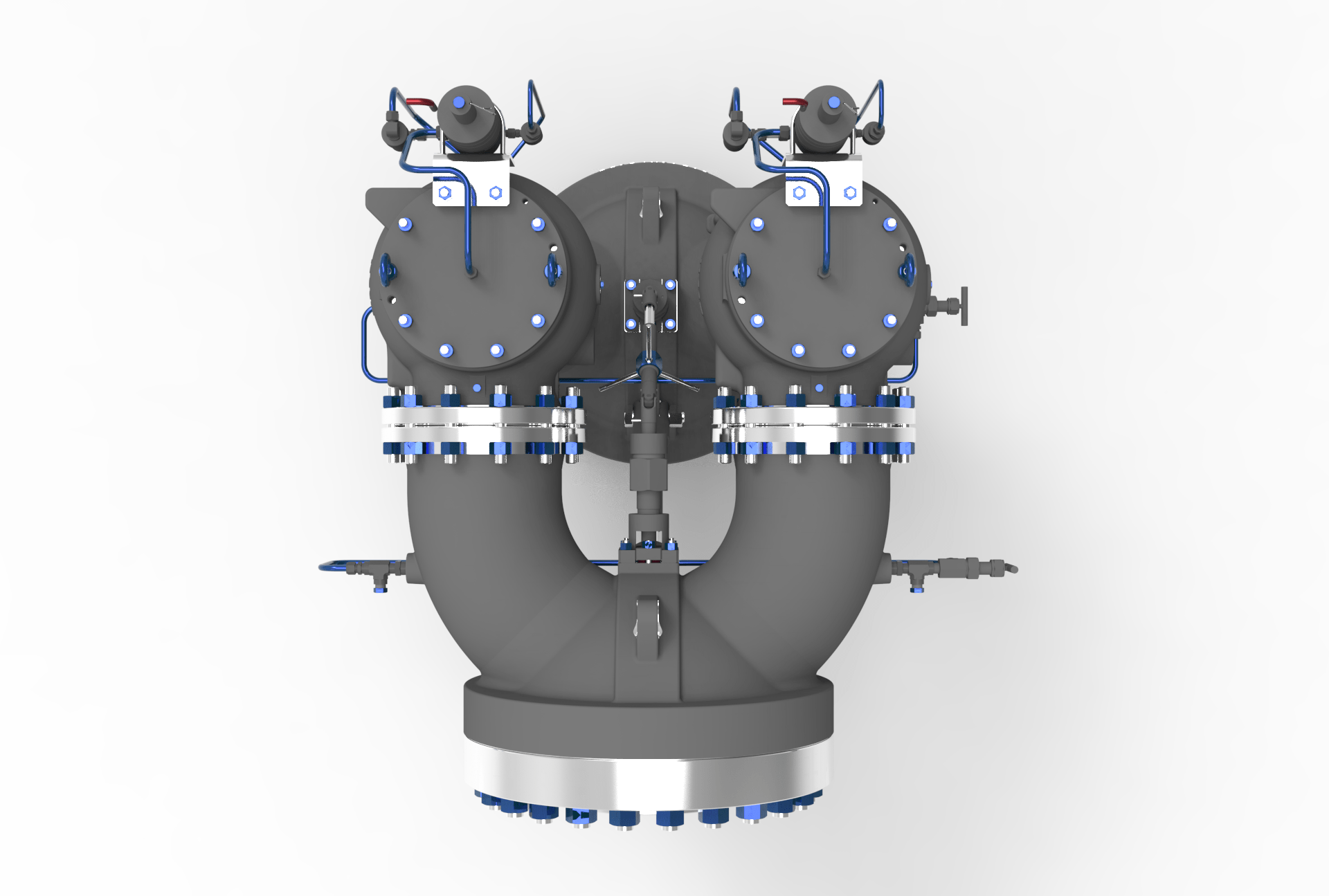

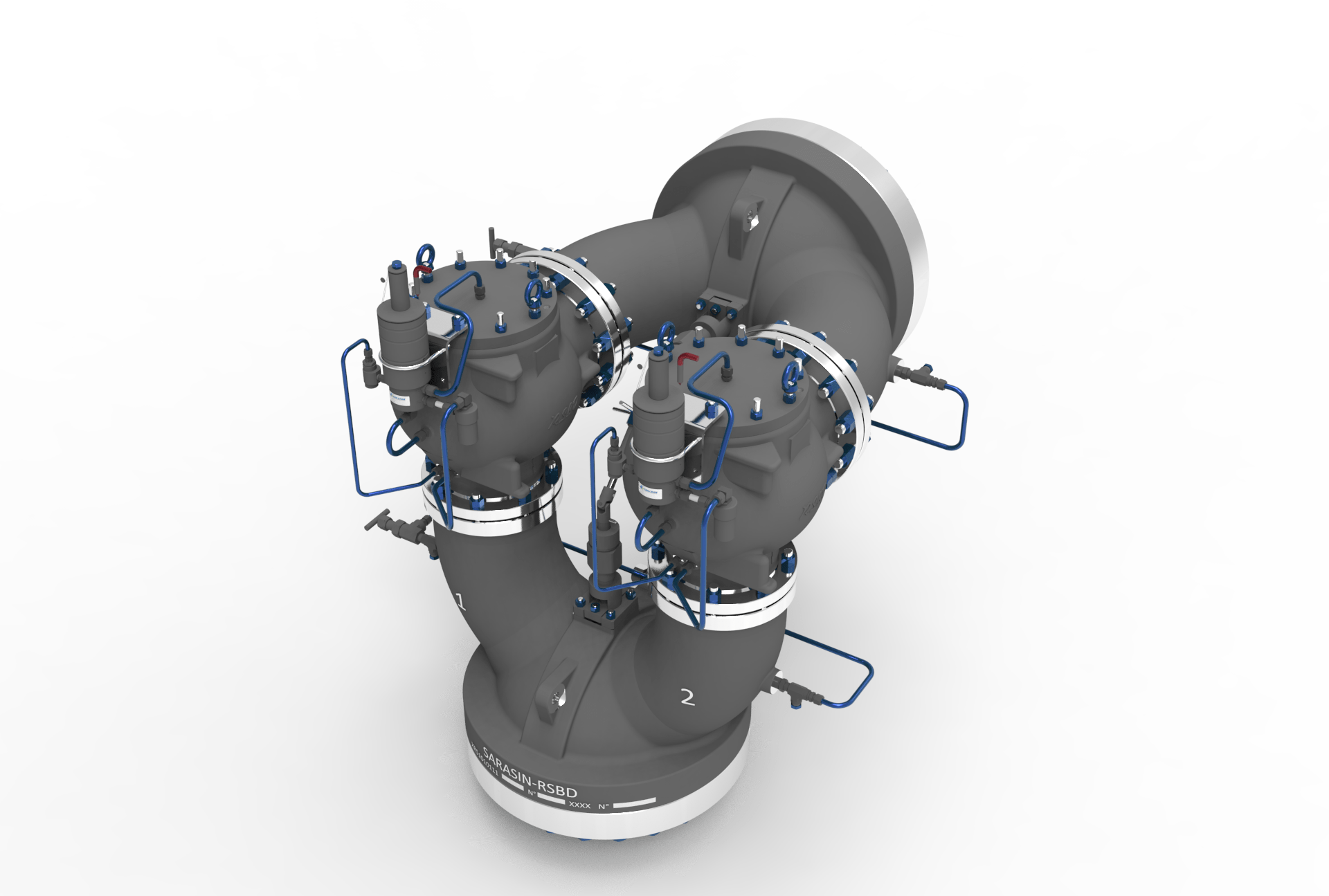

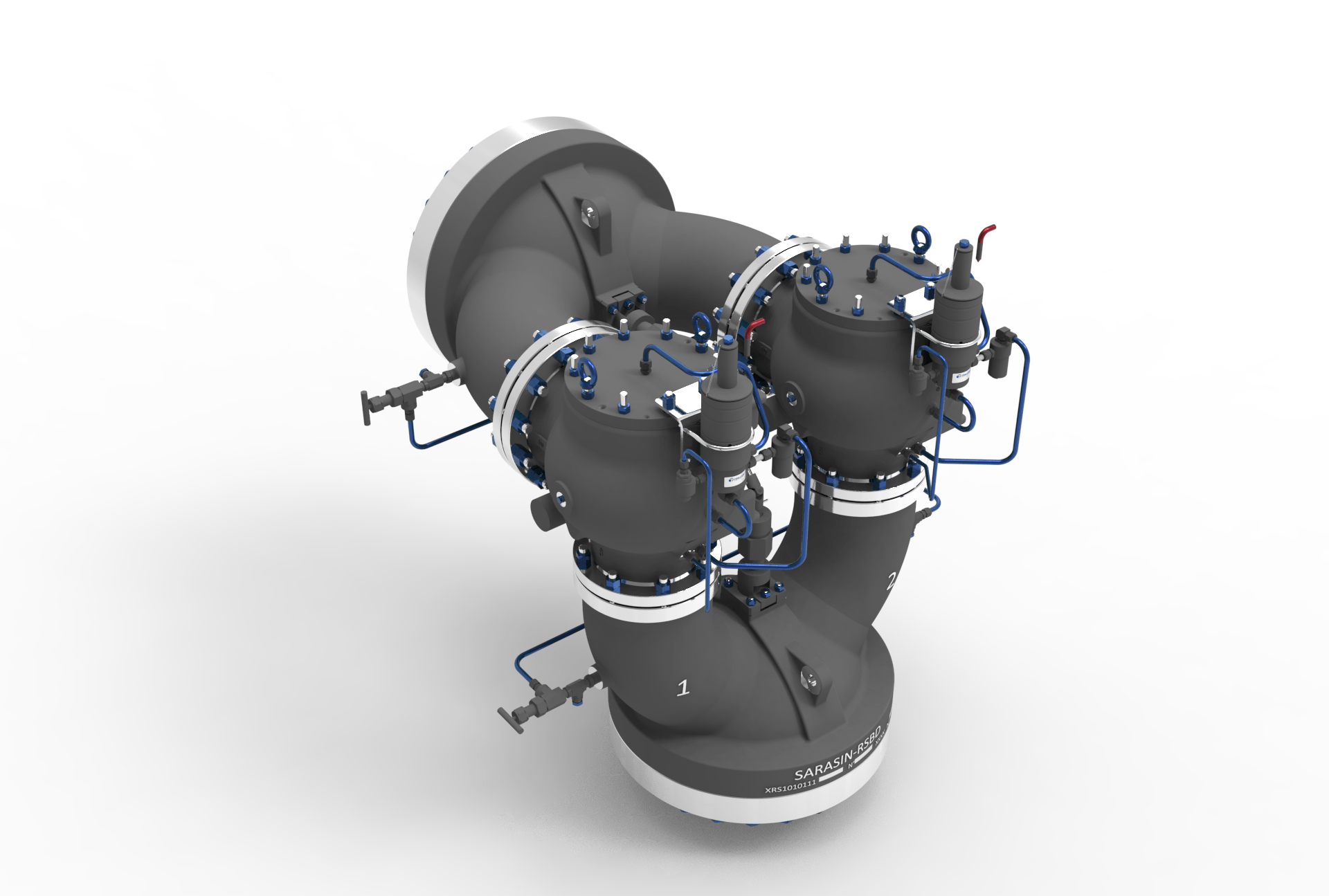

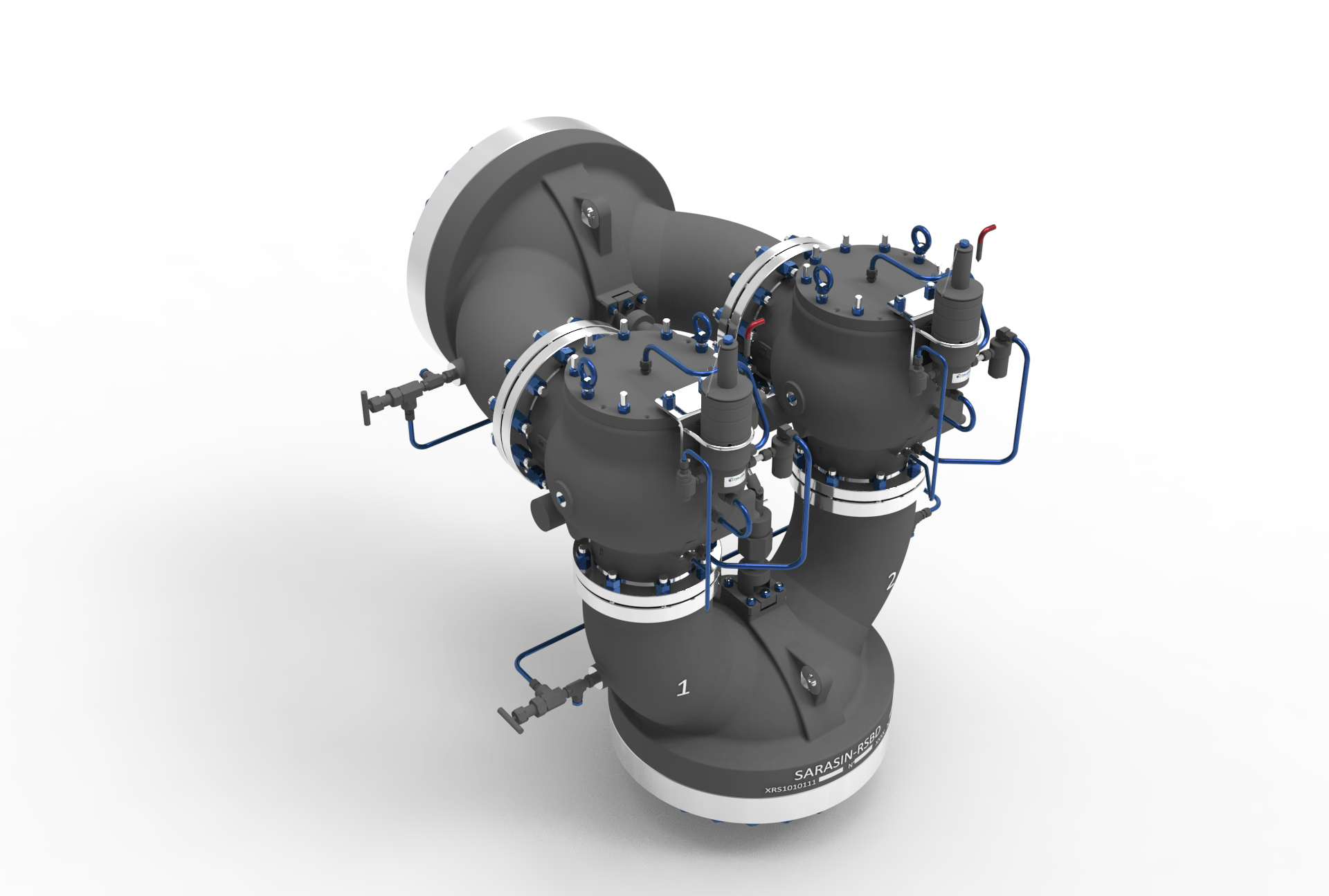

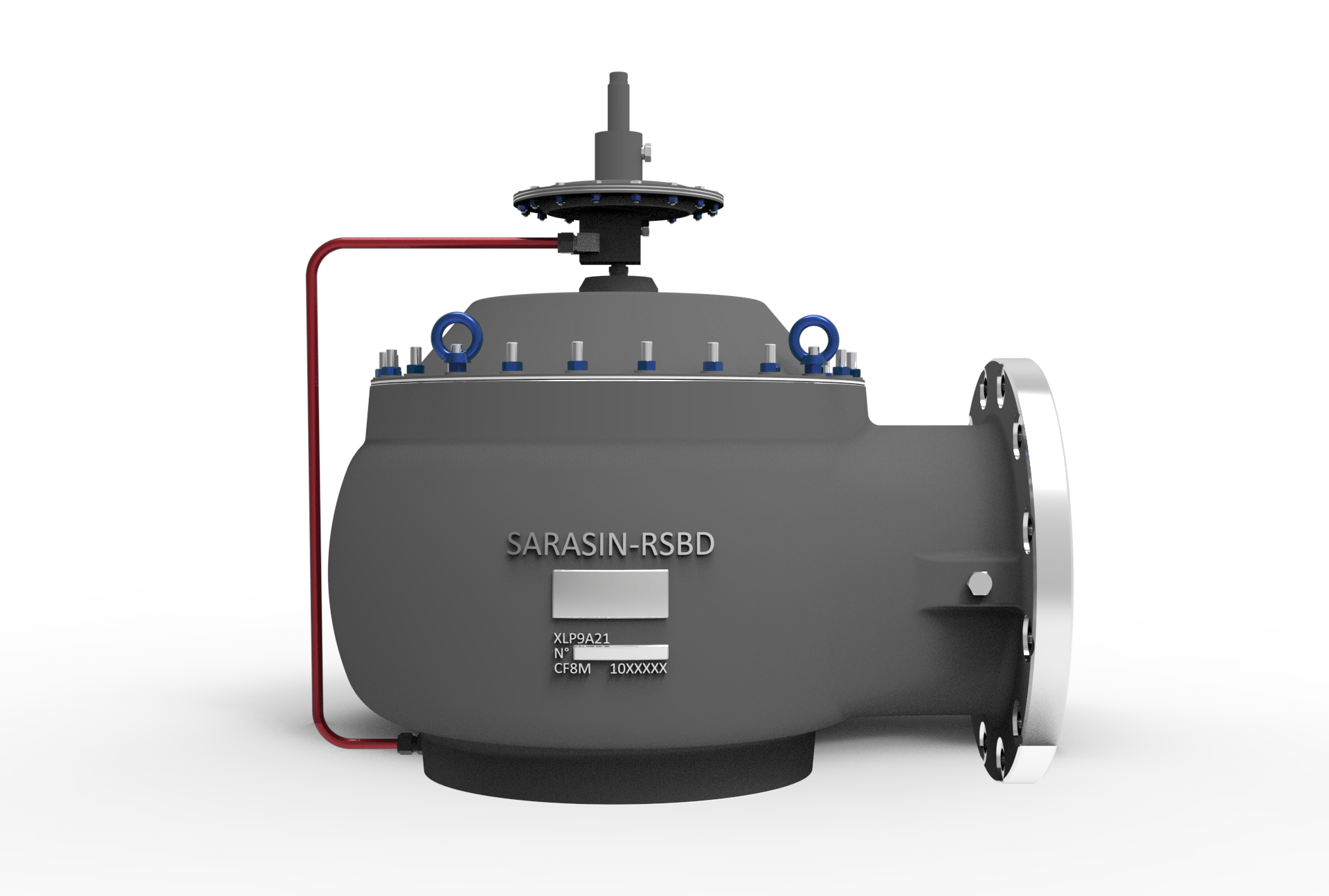

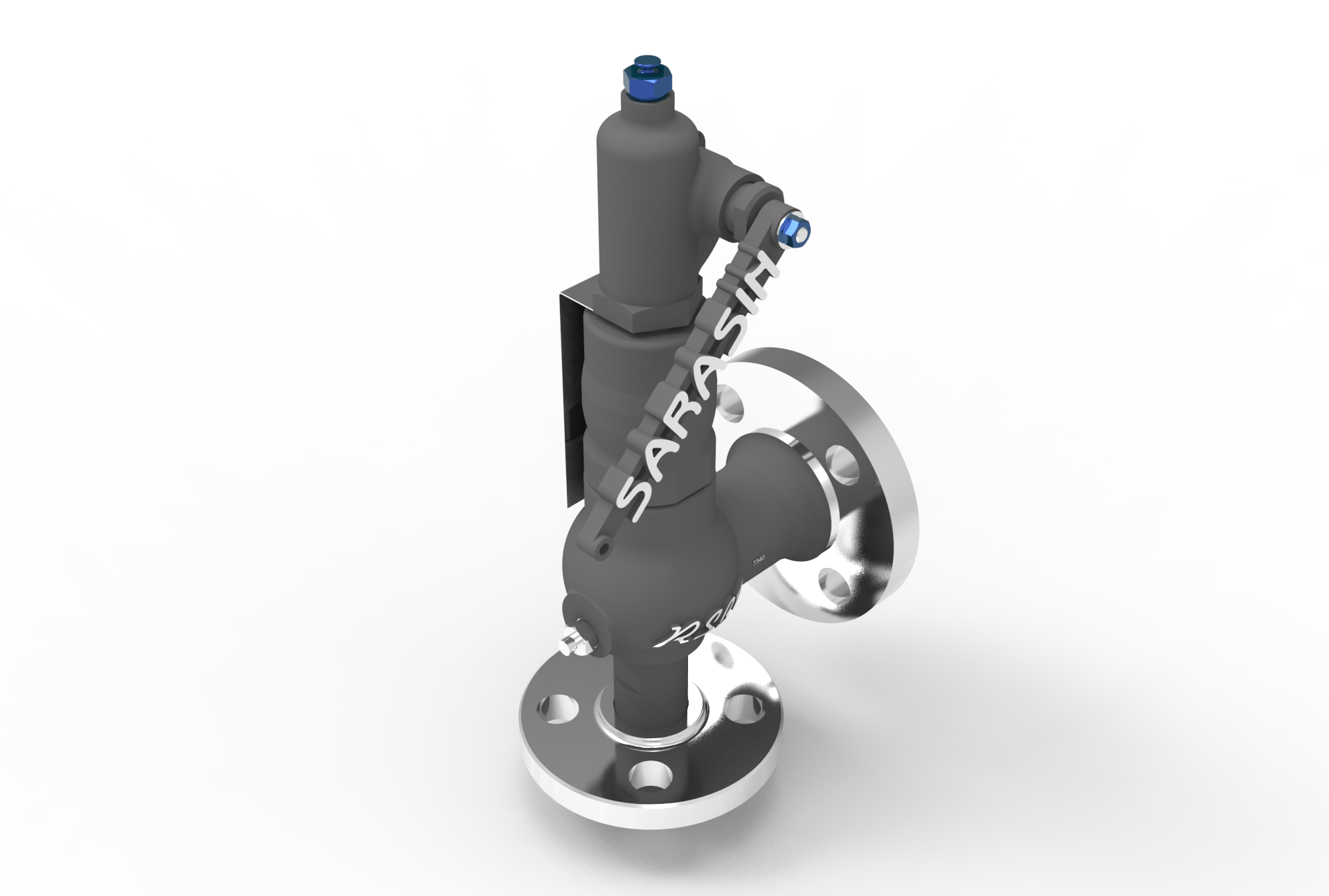

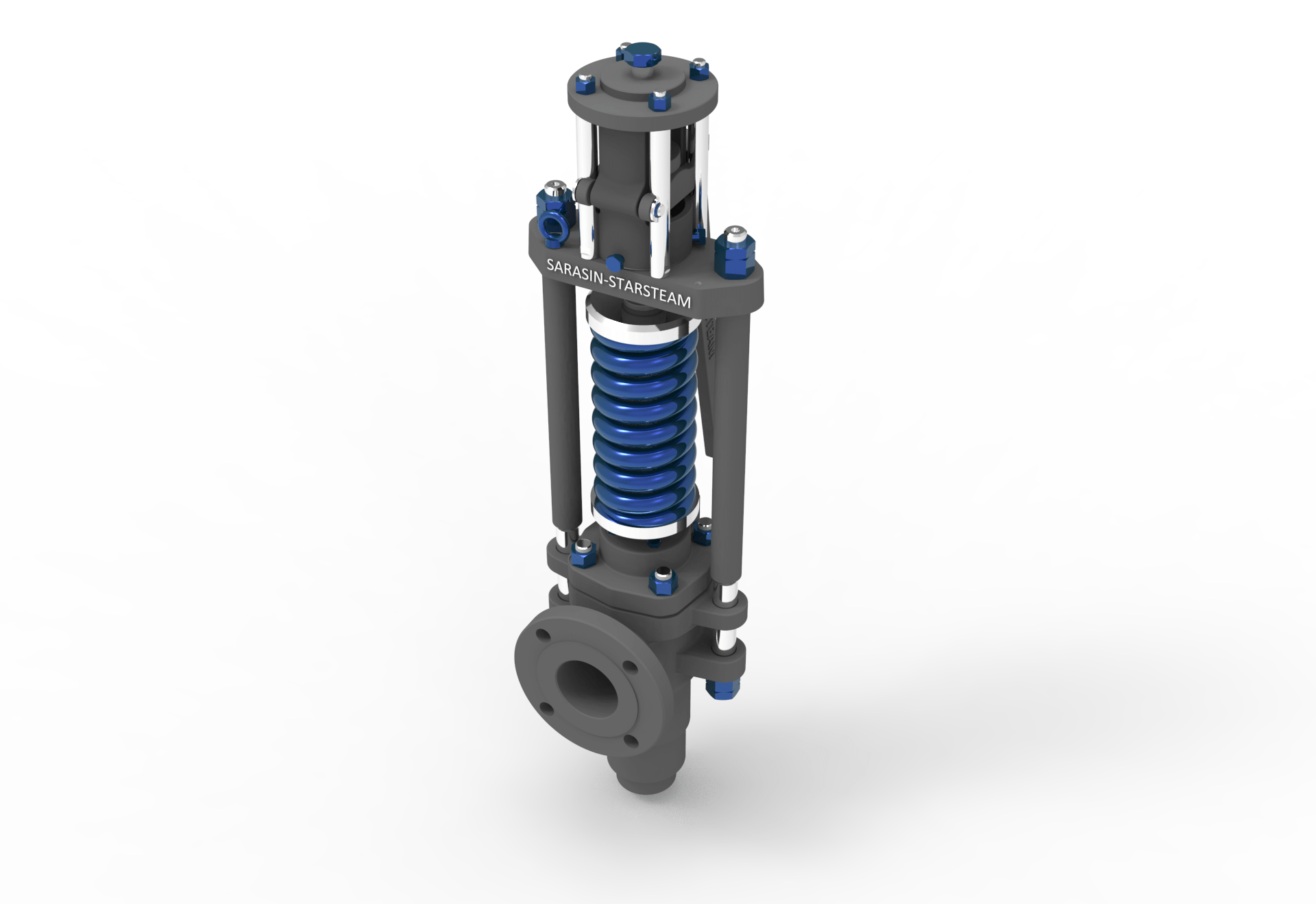

Sarasin-RSBD®

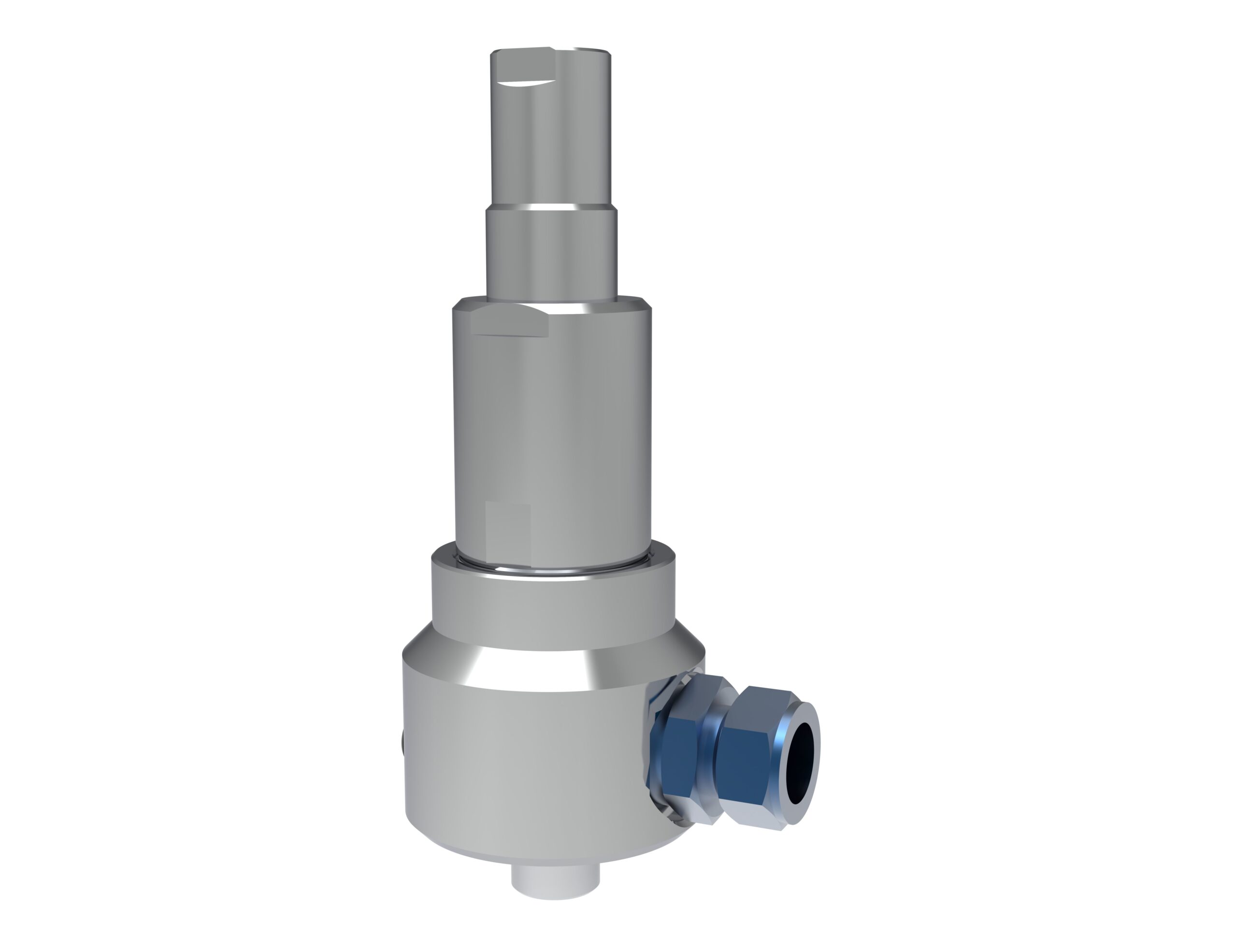

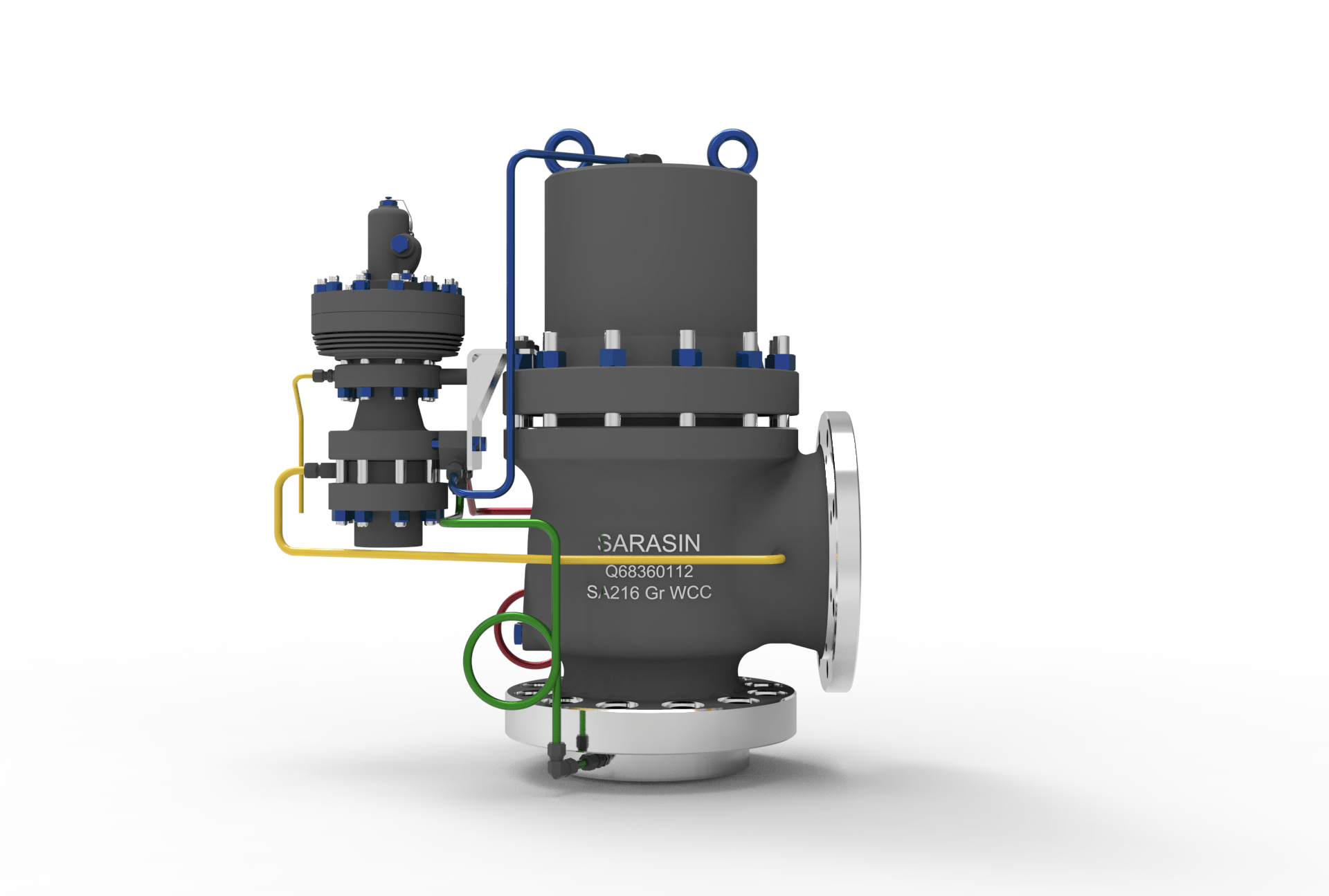

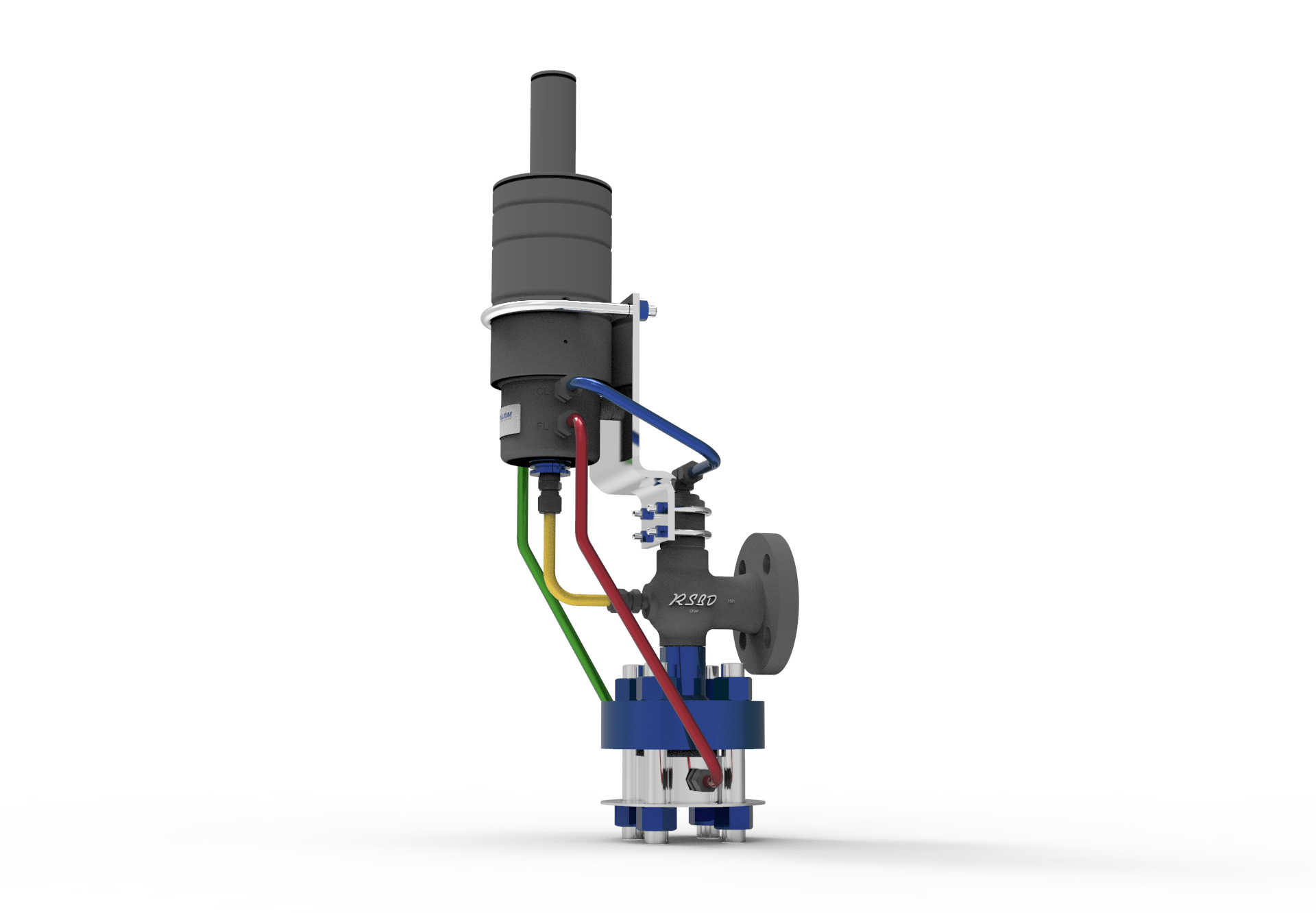

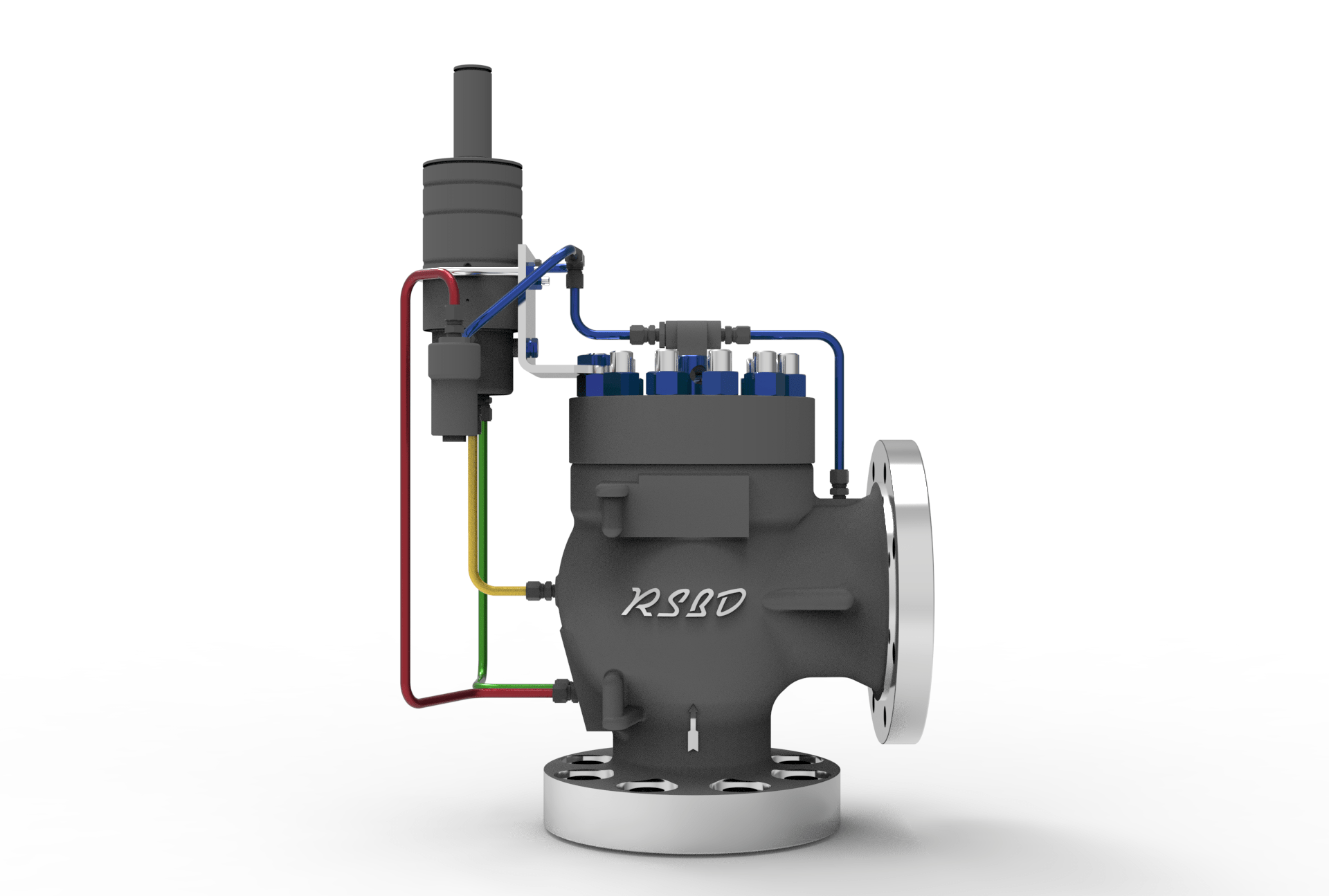

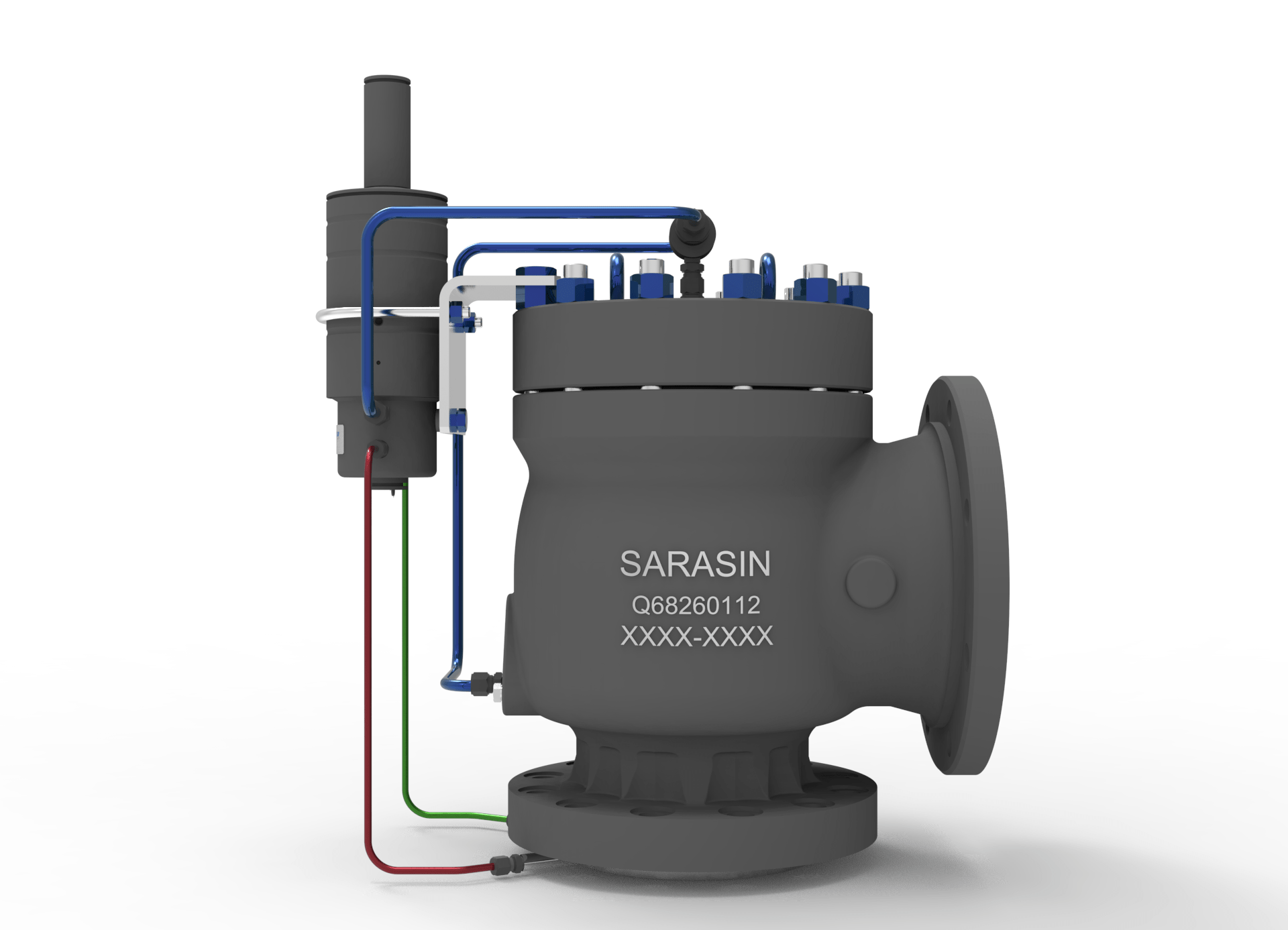

Starvalve (RS type) Changeover Valve

The Sarasin-RSBD® Starvalve series of changeover valves provides a safe and efficient method of switching from an active to a standby pressure relief valve.

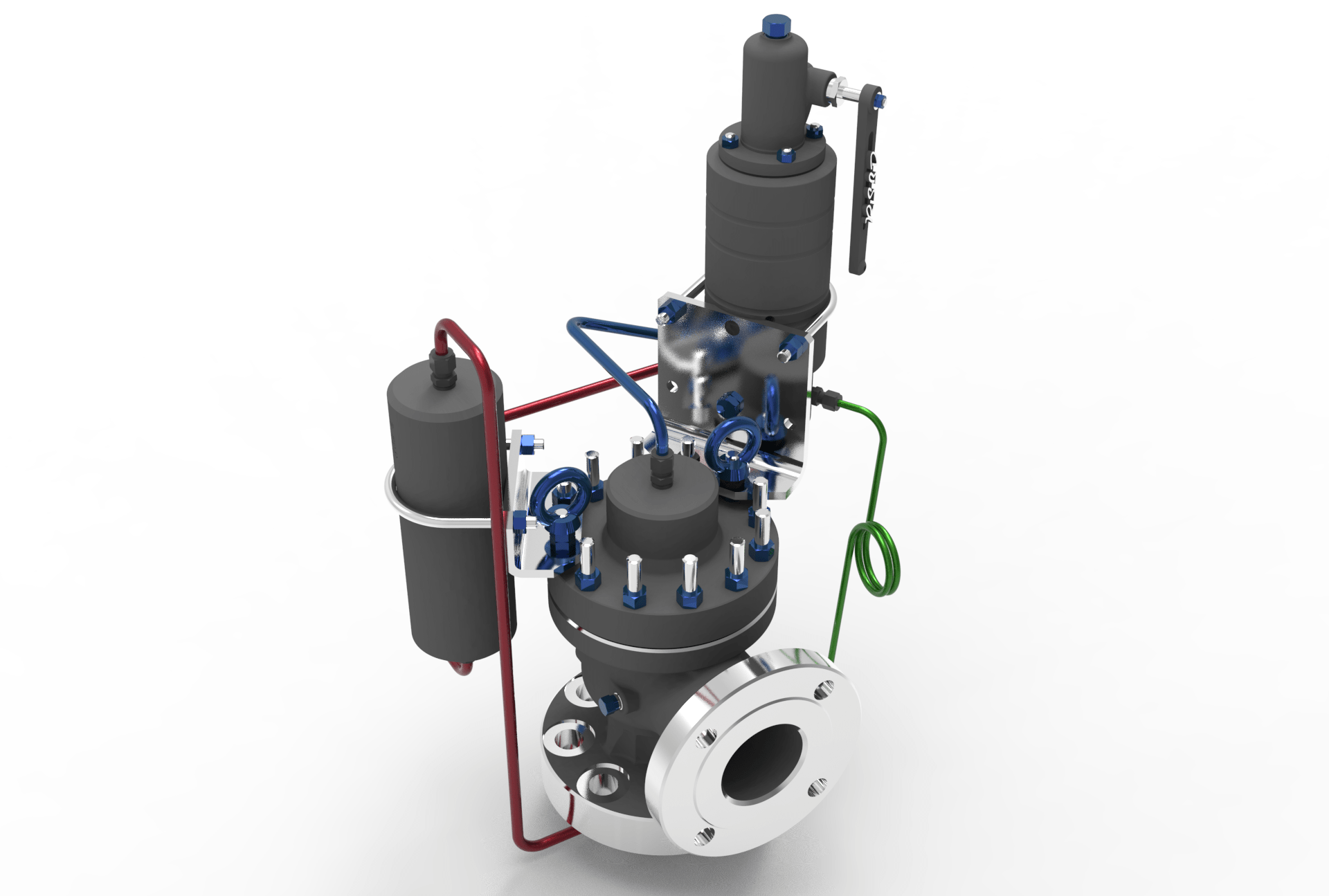

Due to the changeover valve design, no seat lapping is required for maintenance, meaning there are minimal spare parts and a reduced cost of ownership. It reduces the risk of a pressure relief valve chattering from excessive pressure drop through traditional shuttle type changeover valves. The Sarasin-RSBD® Starvalve is a rotor type changeover valve which maintains a pressure drop of pressure below 3% through its body. This changeover valve is designed for use in refineries within the petrochemical and cryogenic industries.

KEY FEATURES & BENEFITS

- Rotor type maintaining a pressure drop of pressure below 3% through its body

- Clear, positive indication of the active pressure relief valve

- Tested packing design plus minimal leak points ensure reduced fugitive emissions

- No seat lapping is required for maintenance

- Minimal spare parts reduce the cost of ownership

- Simple operation, built-in seat equalization, and no special tool requirements minimize the total valve operating time

- Tandem design (single way) for dual pressure relief valves which are discharging into a closed header system

APPLICATIONS

- Refineries Petrochemical and Chemical installations

DESIGN STANDARDS

- ASME B16.34, PED 2014/68/UE

DESIGN RATINGS

- ASME Class 150 to 600

SIZE RANGE & DIMENSIONS

- Single way: 50mm (2 inches), 2 x 50mm (2 inches) to 250mm (10 inches), 2 x 250mm (10 inches)

- Double way: 50mm (2 inches) – 2 x 25mm (1 inch) to 250mm (10 inches) – 2 x 200mm (8 inches)

TEMPERATURE RANGE

- -60ºC – 427ºC (-76°F – 800°F)

CAPACITY

- Individually calculated and selected for each process application

MATERIALS

- Carbon steel, various carbon & chrome moly steels austenitic stainless steels