CHECK VALVES

Check valves, also known as non-return, one-way valves, or flow check valves, are crucial components in flow control solutions across various industrial sectors. Trillium Flow Technologies™ check valves are expertly engineered to prevent backflow that could contaminate or damage flow systems and optimize performance under a range of operating pressure conditions and environments.

JUMP TO SECTION

Types of Check Valves

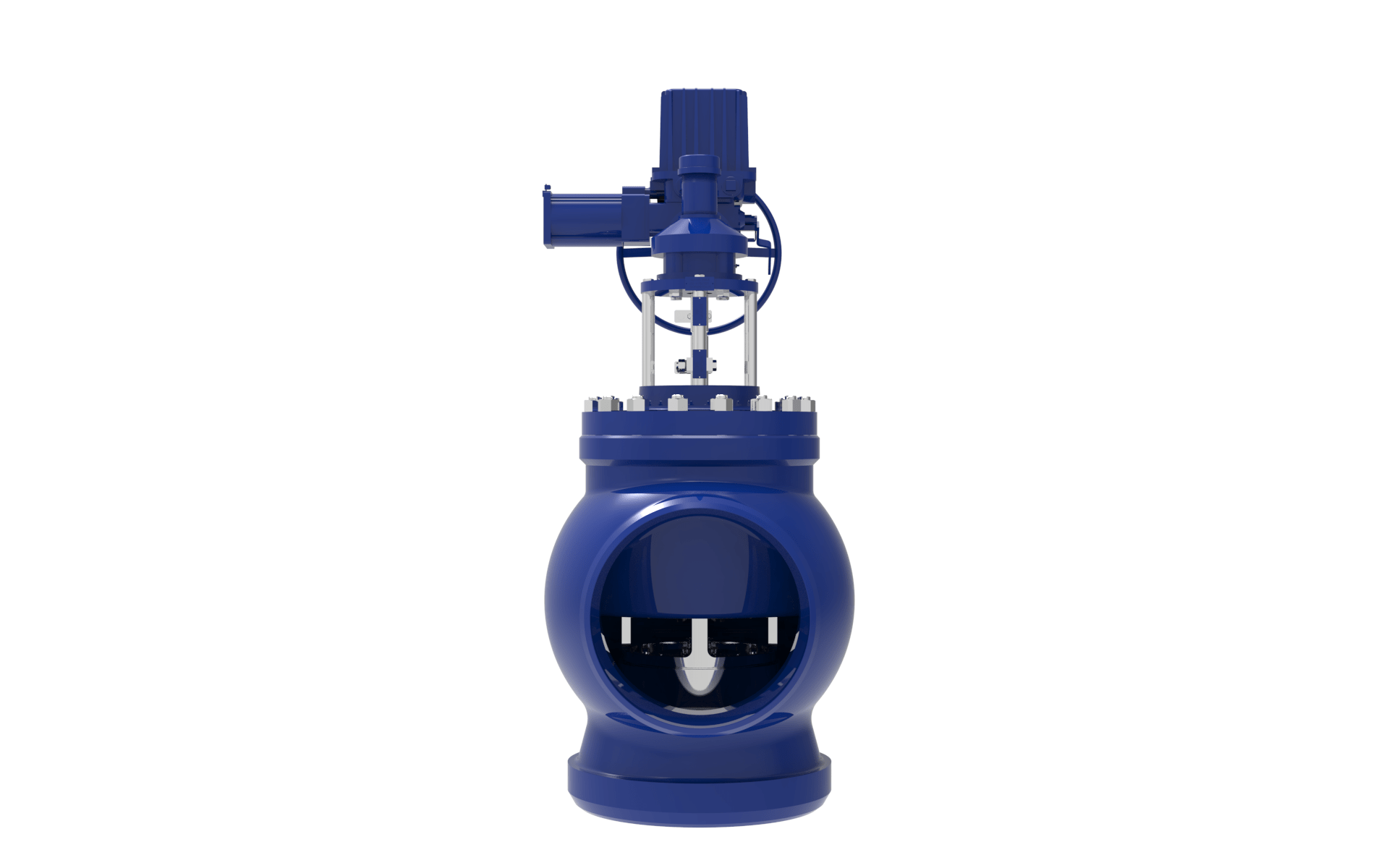

Boiler Feed Check Valve

Boiler Feed

Check Valve

Engineered to prevent reverse flow in high-pressure feedwater and steam applications, this type of check valve offers double protection with positive and power-assisted closure. Its streamlined design minimizes pressure drops, providing secure flow control.

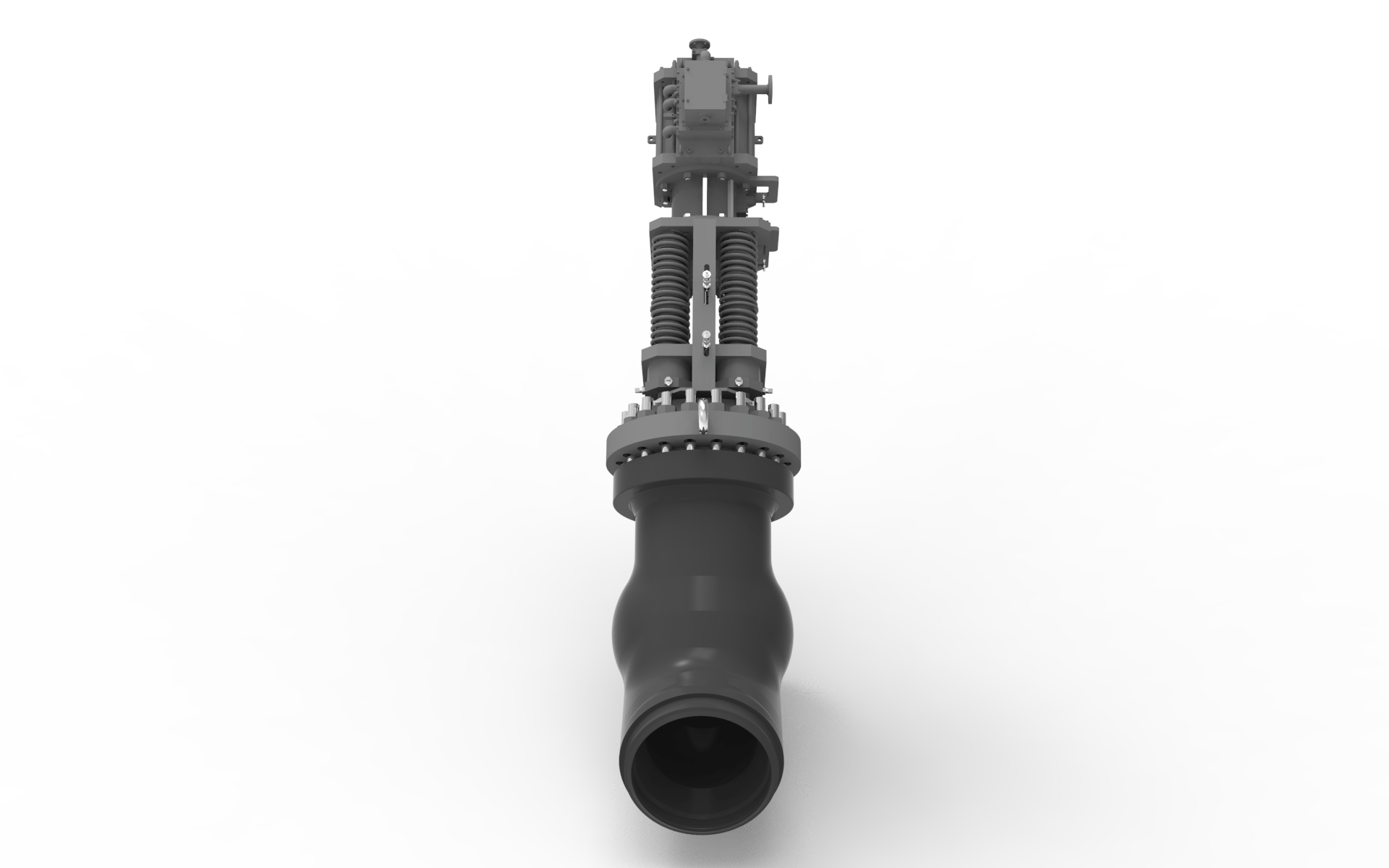

Compressor Check Valve

Compressor

Check Valve

Trillium Flow Technologies™ compressor check valves ensure rapid, reliable closure during trip-outs or shutdowns, providing positive protection for blowers and compressors. This design offers tight sealing, low-pressure drop, and power-assisted quick closure to minimize operational risks.

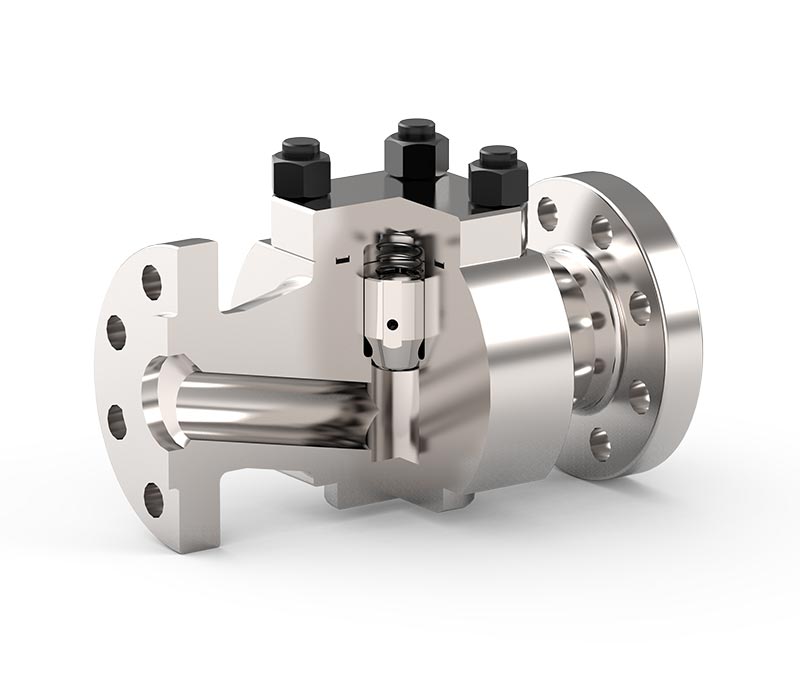

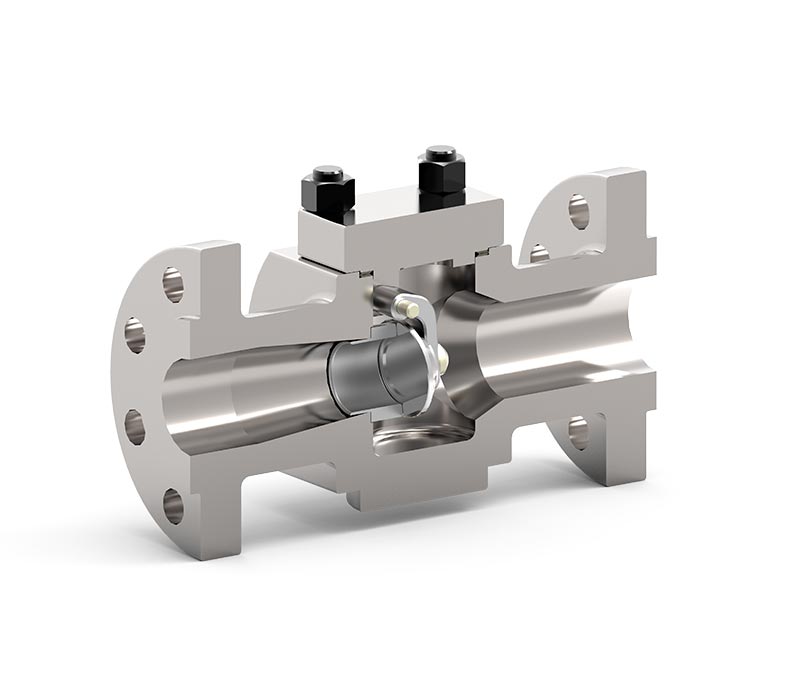

Wye Type Check Valve

Wye Type

Check Valve

The wye-type check valve, with its Y-pattern design, minimizes pressure loss and ensures tight sealing with beveled seats. Ideal for high-pressure steam and water isolation, it offers rapid closure, tight shutoff, and reduced valve stem failure.

Why Choose Trillium Flow

Technologies™ Check Valves?

Nothing Found

Brands You Can Trust

Our family of valve brands are trusted for their field-proven performance across diverse industries, including oil and gas, renewable and traditional power, nuclear power, and water management.

The Atwood & Morrill® brand has been renowned since 1900 for its engineering excellence and high-quality products. These check valves offer an industry benchmark for turbine protection, offering reliable flow control solutions with a steadfast reputation for performance and durability.

Red Point® is known for high-quality valves across various industries worldwide. Red Point check valves are integral to sectors like oil and gas, ensuring reliable flow control and minimizing downtime.

SUCCESS STORY

Mitigating Closure Issues for Fermi NPP

The Fermi nuclear power plant in Detroit, USA, had issues with wear between seats and disc arm bore in their feed water check valves. Left unchecked, these issues lead to more frequent maintenance needs and potentially costly repairs.

In 2010, Trillium Flow Technologies™ installed two modification kits to feed water check valves, upgrading the disc and arm to a two-piece design, ensuring tight fitting and correct installation as well as simplifying the valve design for eliminated friction and shaft linkage.

Downstream Oil and Gas

Downstream

Oil and Gas

By preventing reverse flow, check valves help avoid dangerous situations such as leaks, contamination, and the risk of fires or explosions, thus ensuring the safety and reliability of gas transmission systems used in the downstream sector.

Midstream Oil and Gas

Midstream

Oil and Gas

Trillium Flow Technologies™ check valves are field-tested and proven in the most demanding midstream environments to ensure the bulk storage and transportation of oils and gases remain efficient and secure, and the risk of leaks is minimized.

Power Generation

Power

Generation

Check valves are employed in nuclear power plants and traditional power plants to control the flow of steam and water, ensuring efficient and safe operations.

Water and Wastewater

Water and

Wastewater

Many water treatment and distribution systems use our check valves to prevent the reverse flow of water, helping maintain water quality and system integrity.