The pressure relief valve is one of the most important types of safety valves. It was designed to control or relieve overpressure levels for optimal functionality in any system, including chemical, petrochemical, power, and oil and gas industries. The valve opens to ease the building pressure by allowing it to escape, the valve then closes when it returns to a stable level. It prevents potential injury, limits the failure of equipment, and controls the pressure in a system with a point of release.

There are many kinds of relief valve benefits and features. They are designed to provide high integrity performance and repeatability in the power industry, particularly at high-pressure and high temperatures. Each valve provides a unique level of support and service to ensure that your project or operation runs smoothly, from oil and gas to nuclear power, general industry, or water and wastewater. As long as the valve is properly maintained, there is no risk of injury. Most pressure relief valves fall into the categories of spring-loaded and pilot valves.

The valves are designed as a simple, reliable, system actuated device to protect against overpressure. They are particularly suitable for applications where there is no excessive backpressure. By adjusting the spring load, the valve can be opened at a variety of pressures. The spring force keeps the disk in place, keeping the valve closed. The disk begins to lift when the line pressure exceeds the set pressure, allowing the fluid to flow through the outlet and relieve the pressure. As the inlet pressure increases, the disk lifts further. By the time the disk reaches its designed value, the valve is fully open, and the system pressure is released. If the system overpressure falls below the spring force, the spring retracts the disk to close the valve, preventing further fluid leakage.

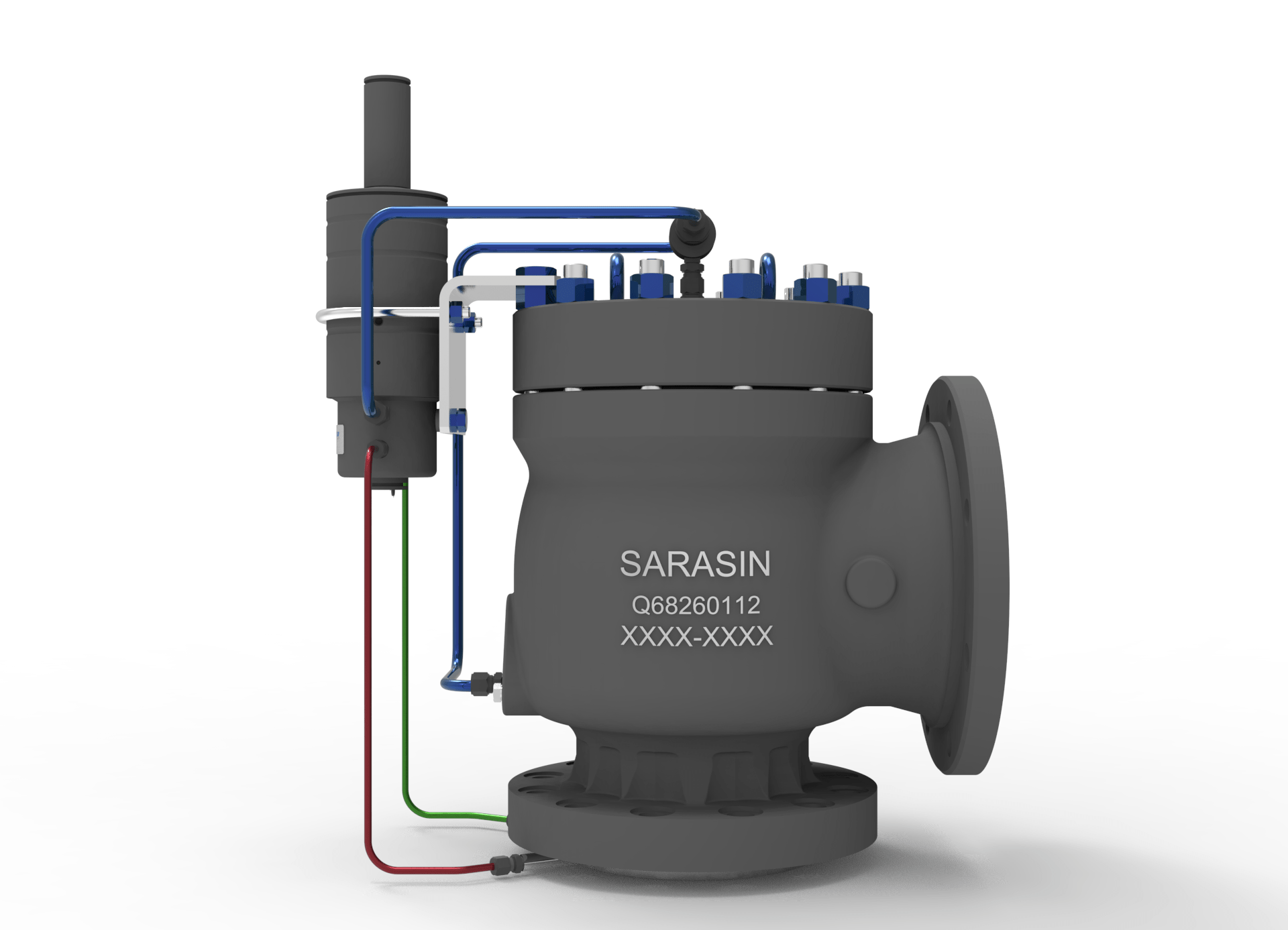

This type of valve is a self-actuated auxiliary pressure relief that controls the pressure-relieving process. It is used to sense the process pressure and to pressurize the dome pressure chamber, which controls the valve opening or closing. The inlet pressure is directed to a small safety valve that acts on top of the piston. The top of the piston is designed to be larger than the bottom area under fluid contact. The pressure on top pushes the piston to close the relief valve. When the inlet pressure rises above the set pressure, a net upward force acts on the piston, forcing the piston to pop up and release the pressure. They make it possible to handle higher pressures and flow. It’s also much smaller than direct-acting valves rated for the same pressure.

Summary

With Trillium Flow Technologies™, safety always comes first. It’s important to understand that pressure relief valves are necessary to protect your system from failure and thereby protect yourself from a devastating injury. We are here for you every step of the way, especially when it comes to pressure relief valve maintenance. Each one of our STAR service centers is a certified valve repair shop, not just for brands like our Sarasin-RSBD® products, but any manufacturer’s brand of pressure release valves. Whether you have a single valve needing service or numerous valves requiring a complete overhaul, a STAR service center offers the resources, skills, and experience to complete your job efficiently, expertly, and on time.

You can count on Trillium Flow Technologies™ valves for complete flow control success. Our reliable legacy brands like our Sarasin-RSBD® pressure relief valves and our team of dedicated support and services experts ensure that you have a trusted partner who adds value at every phase of your project cycle.