Red Point®

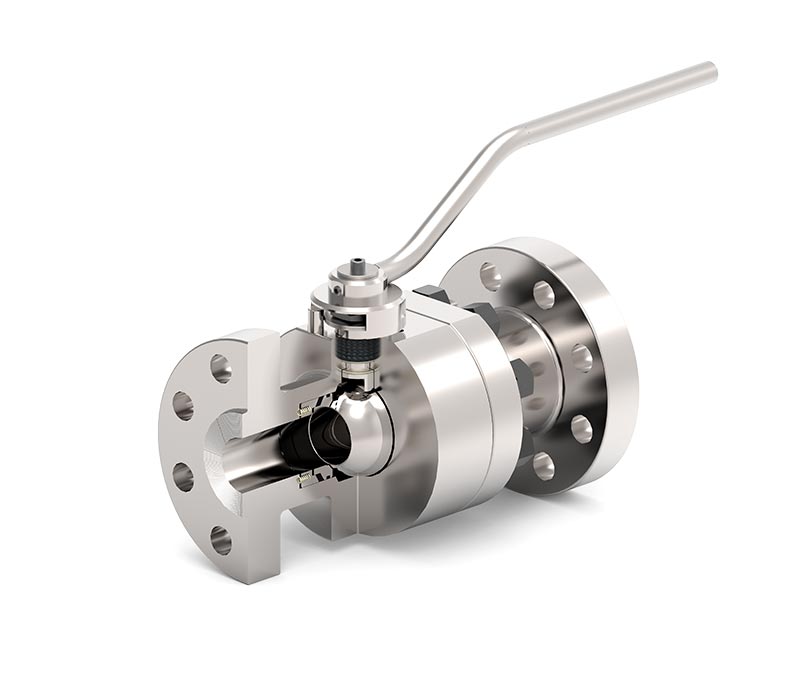

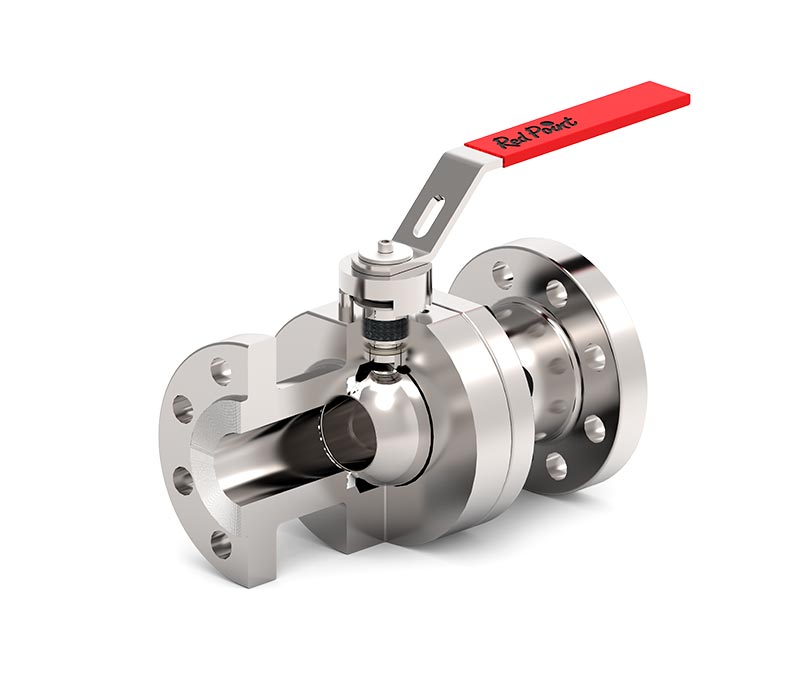

Floating Ball Metal Seated Ball Valves

Red Point’s metal seated floating ball valves can be deployed for a wide variety of applications in the oil & gas, petrochemical, mining, and power industries when high quality, reliable valves are required.

Our metal seated floating ball valves are available in both forged and cast exotic materials, with short delivery times.

Construction

- One Piece Body (Top Entry)

- Split Body (Side or End Entry)

- Anti-Static Device & Blow-Out Proof Stem

End connections

- Flanged

- BW

- SW

- THR

- HUB

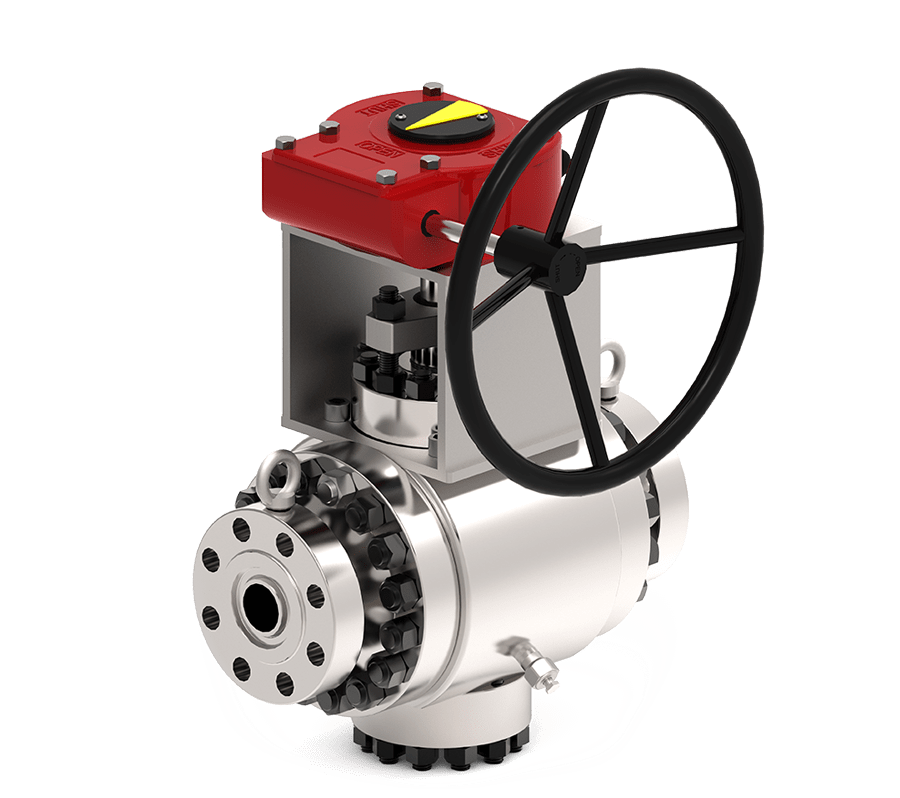

Operated

- Lever

- Gear

- Actuator (pneumatic – electric – hydraulic)

Design & Testing

All available international standards according to API6D, API598, EN12266, MSS SP82, ISO5208, API6A

Face to Face

- ASME B16.10

- EN558

- JIS B2002

- MSS SP72

Fire Safe

- Design and Certified API607, API6Fa, ISO10497

Mounting pad

- ISO5211 – Top Flange

Fugitive emission

- ISO EN15848-1

- ISO EN15848-2

Options

- Extended Bonnet

- Lipseals

- Local CRA

- Overlay

- Heating Jacket

- Drain & Vent

- Mechanically Linked

Size & bore

Forged Valves:

- ANSI 1” – 6”

- DN 25 to DN 100

Cast Valves:

- ANSI 6” to 16”

- DN 10 to DN 400

Pressure range

Forged Valves:

- ANSI 125 to 4,500 lbs

- ISO PN 10 to PN 640

Cast Valves:

- ANSI 125 to 2,500 lbs

- ISO PN 10 to PN 400

Temperature

- -196°C – 816 °C

- -320°F – 1,500°F