Hopkinsons®

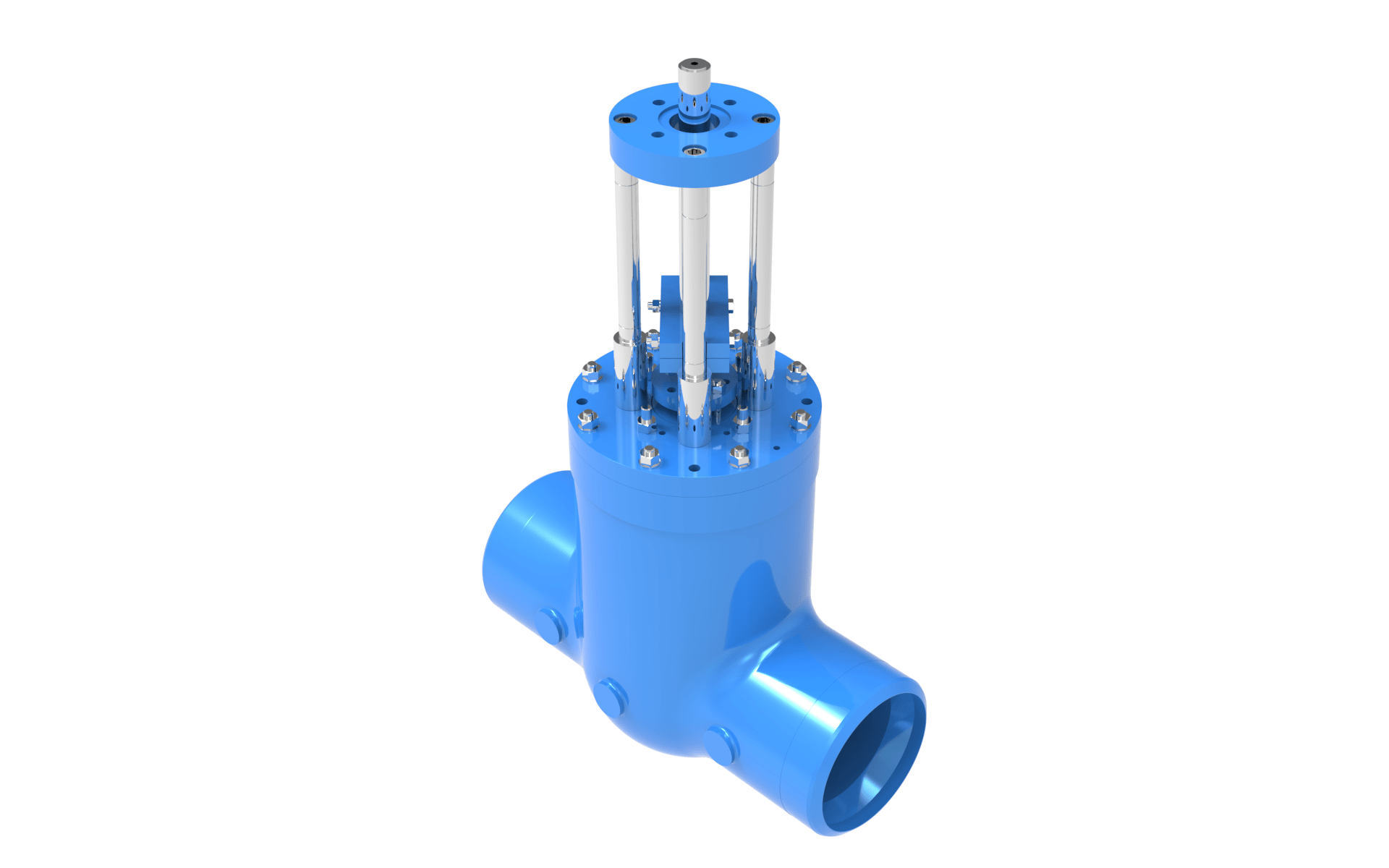

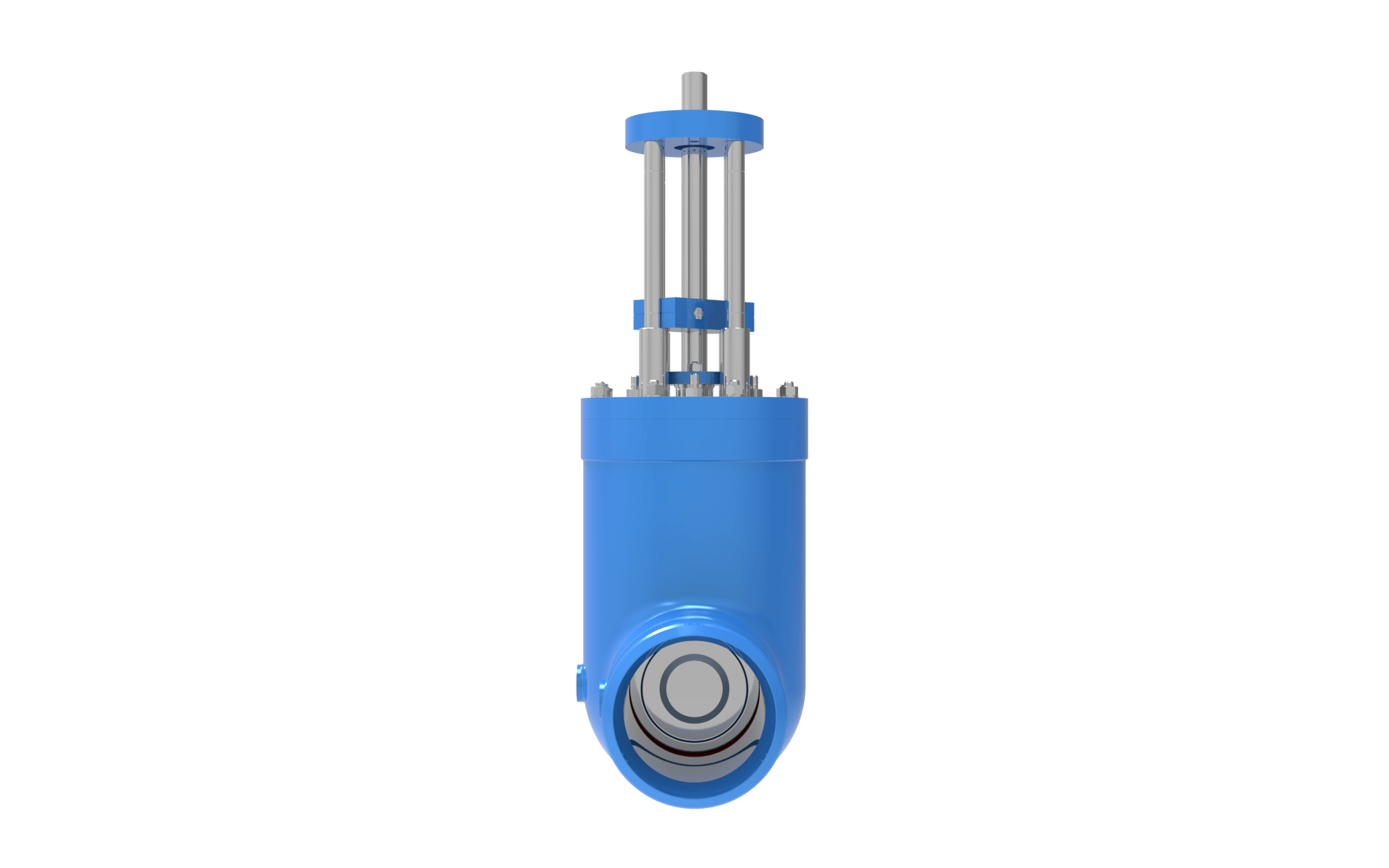

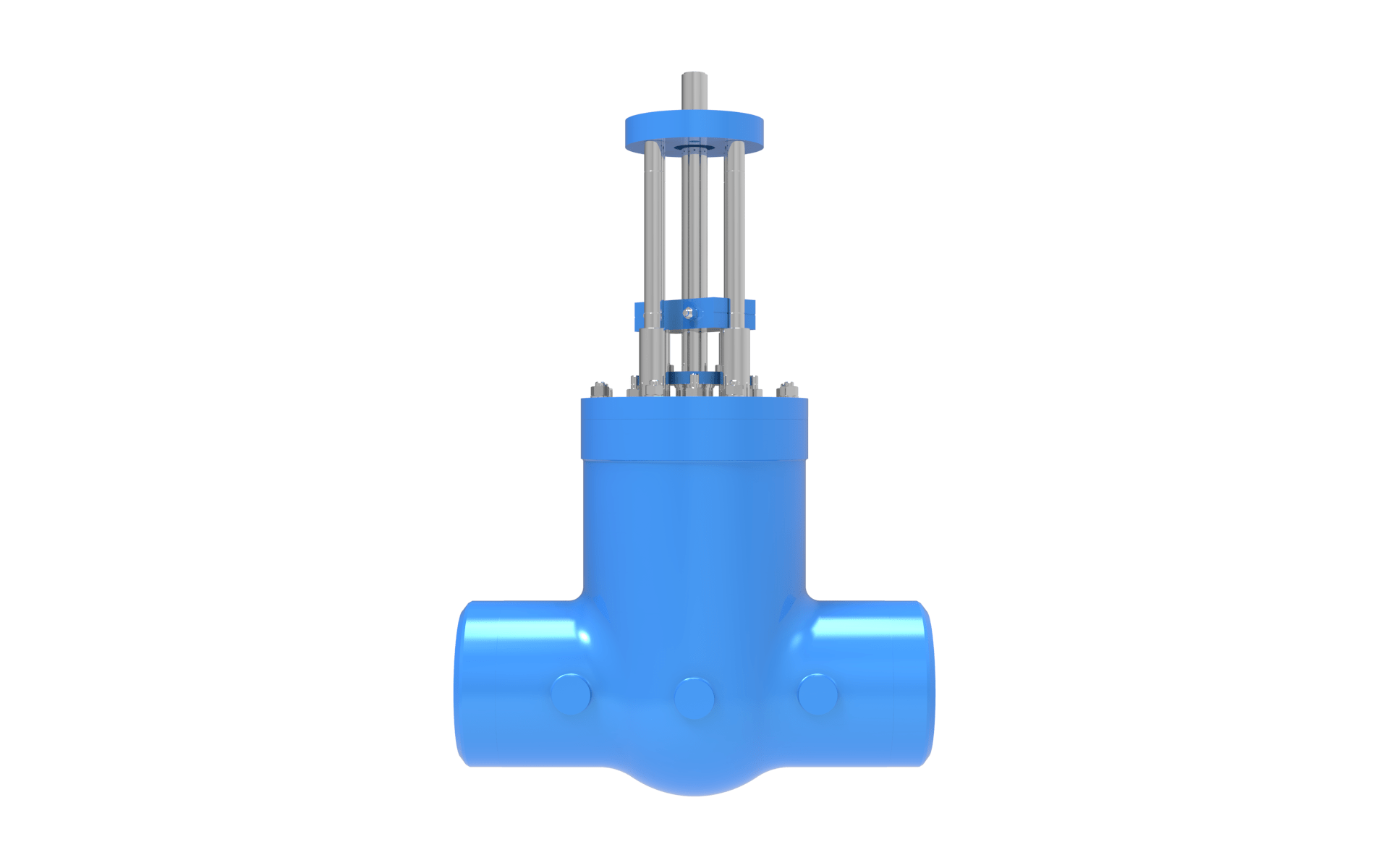

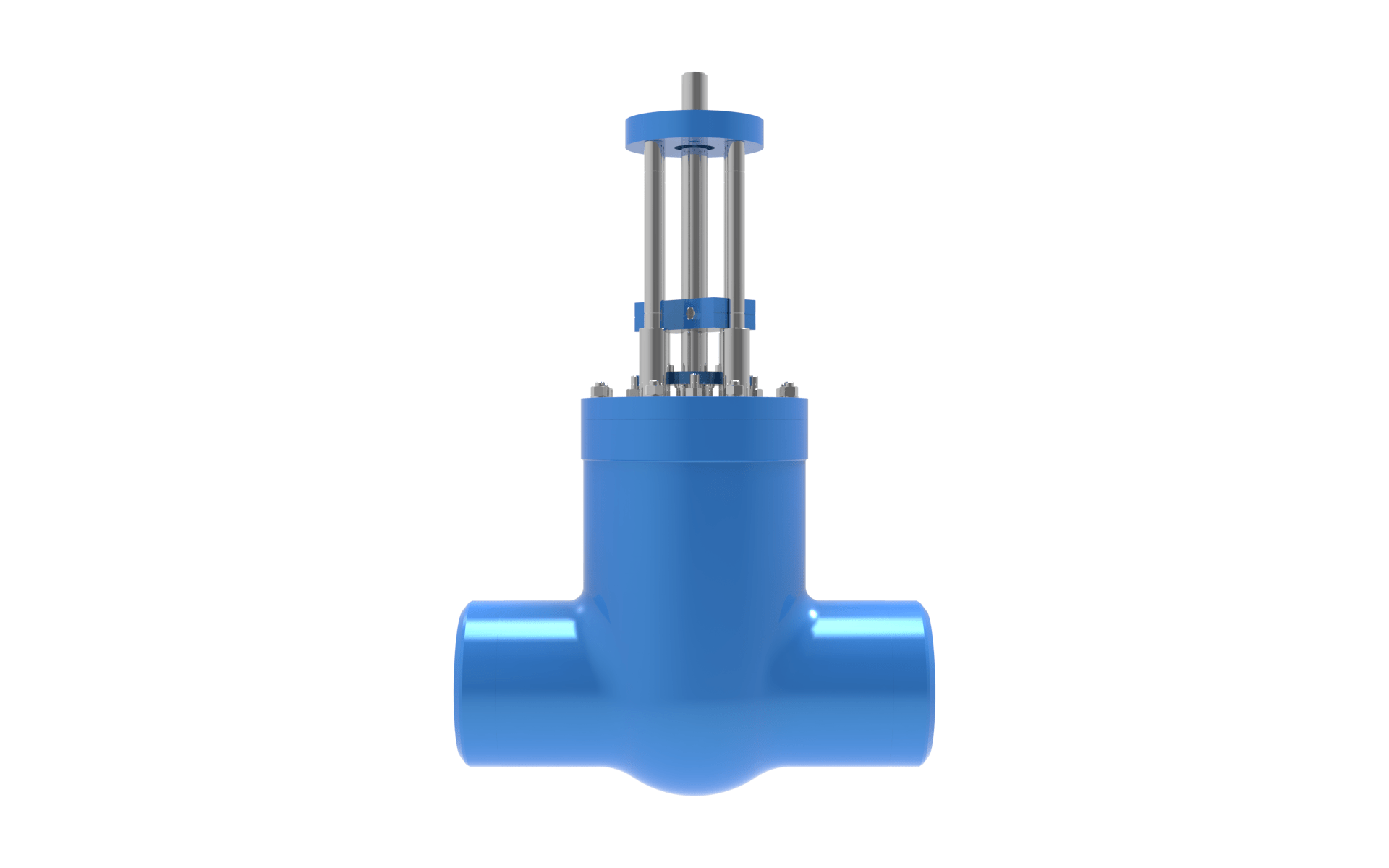

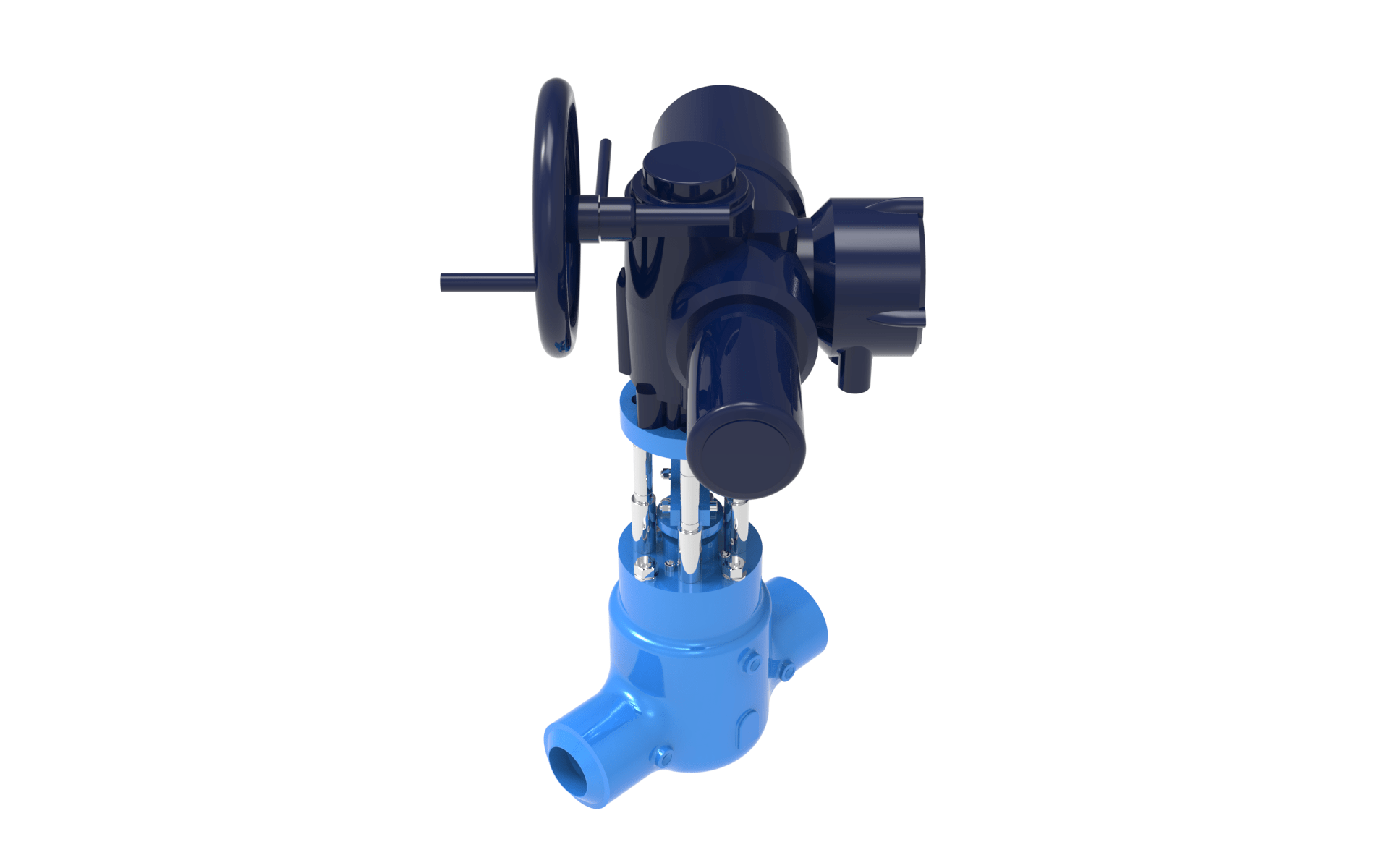

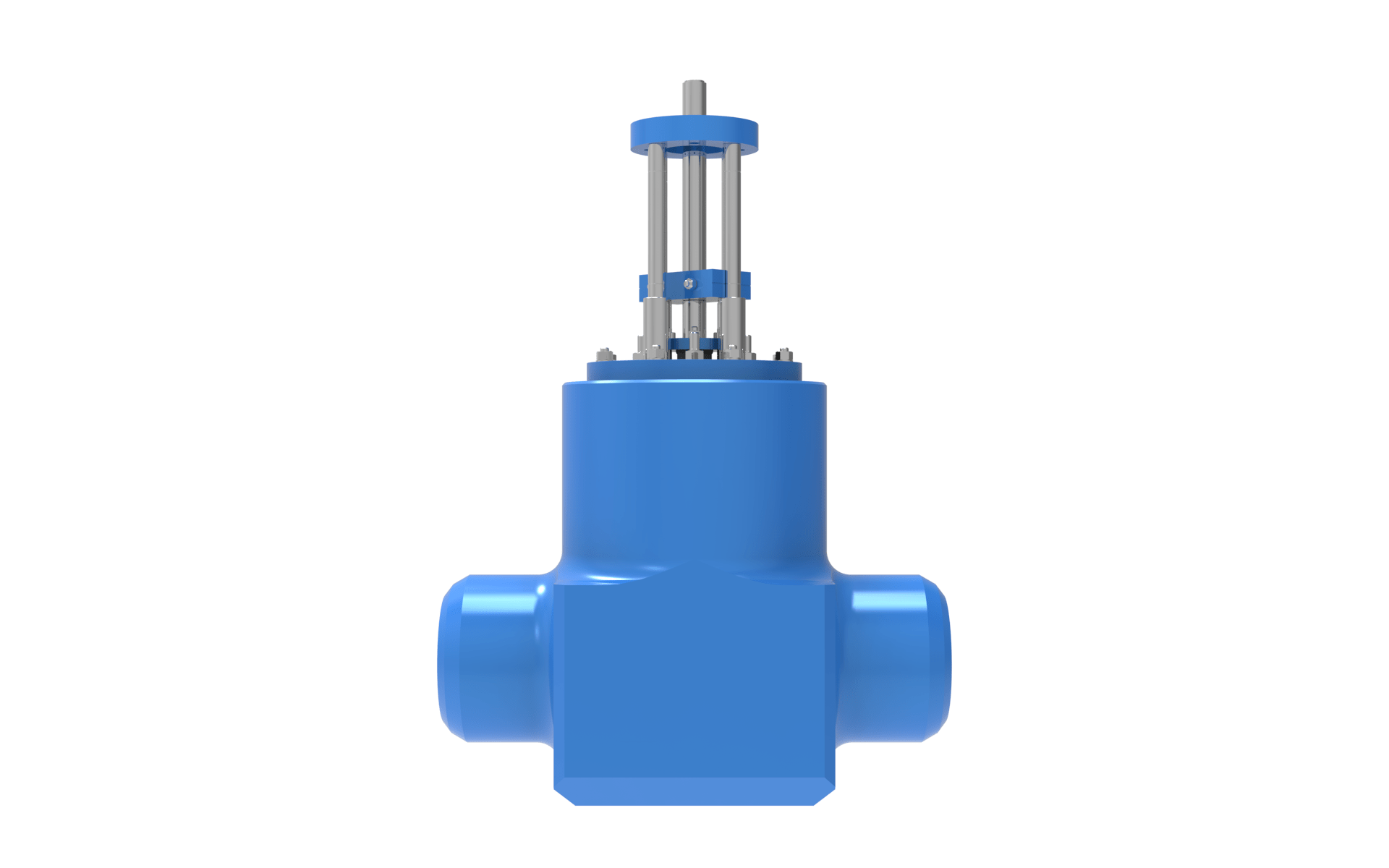

Full Bore & Venturi Parallel Slide Gate

We recommend Hopkinsons® Full Bore & Venturi valves when a gate valve is required for steam or feedwater duty in medium and high pressure ranges.

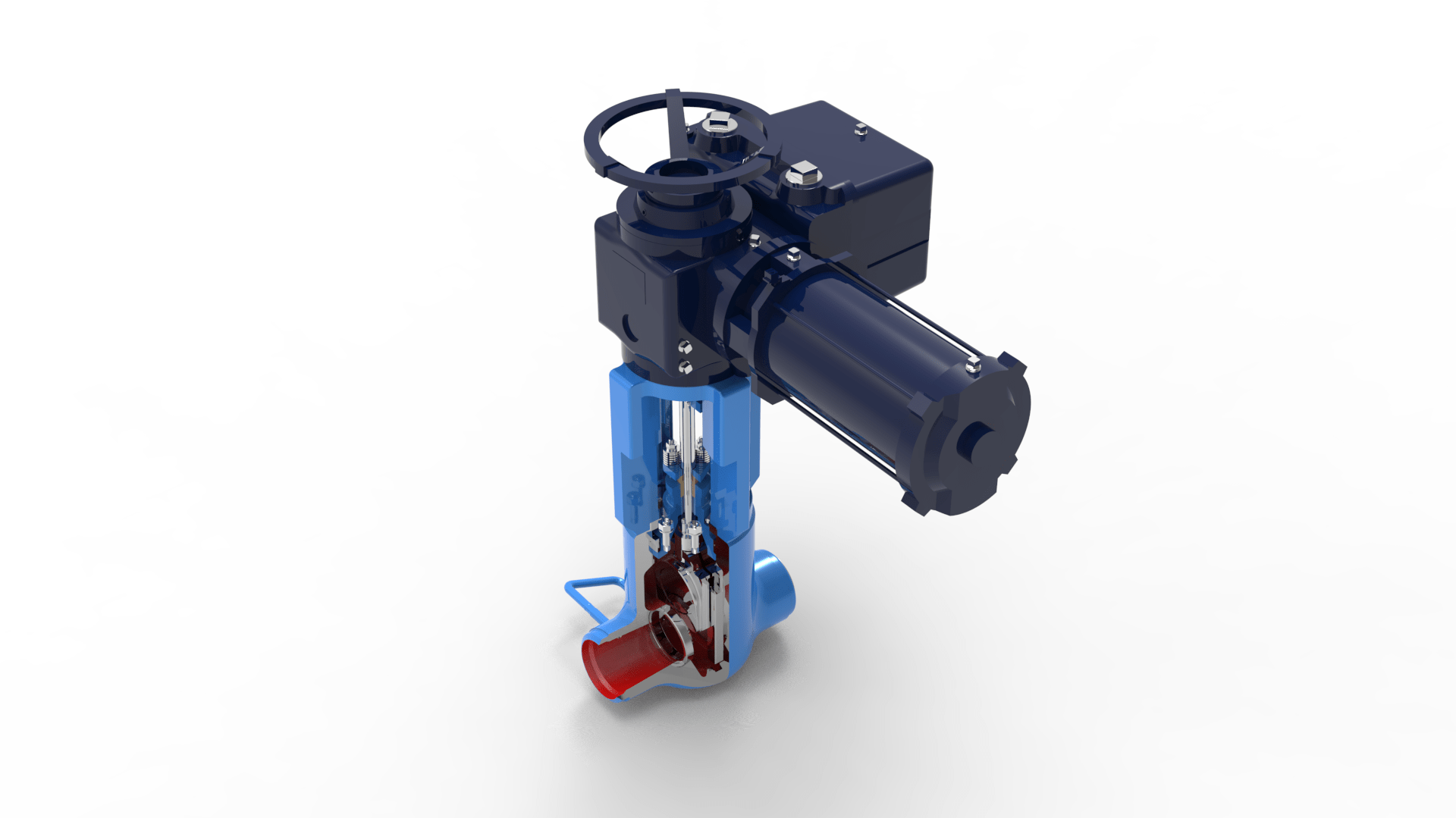

Full Bore: The outstanding feature of the parallel slide design is that of maintaining fluid-tightness without the aid of wedging action. No mechanical stress is exerted between the discs, and there are no problems associated with cool-down of the fluid.

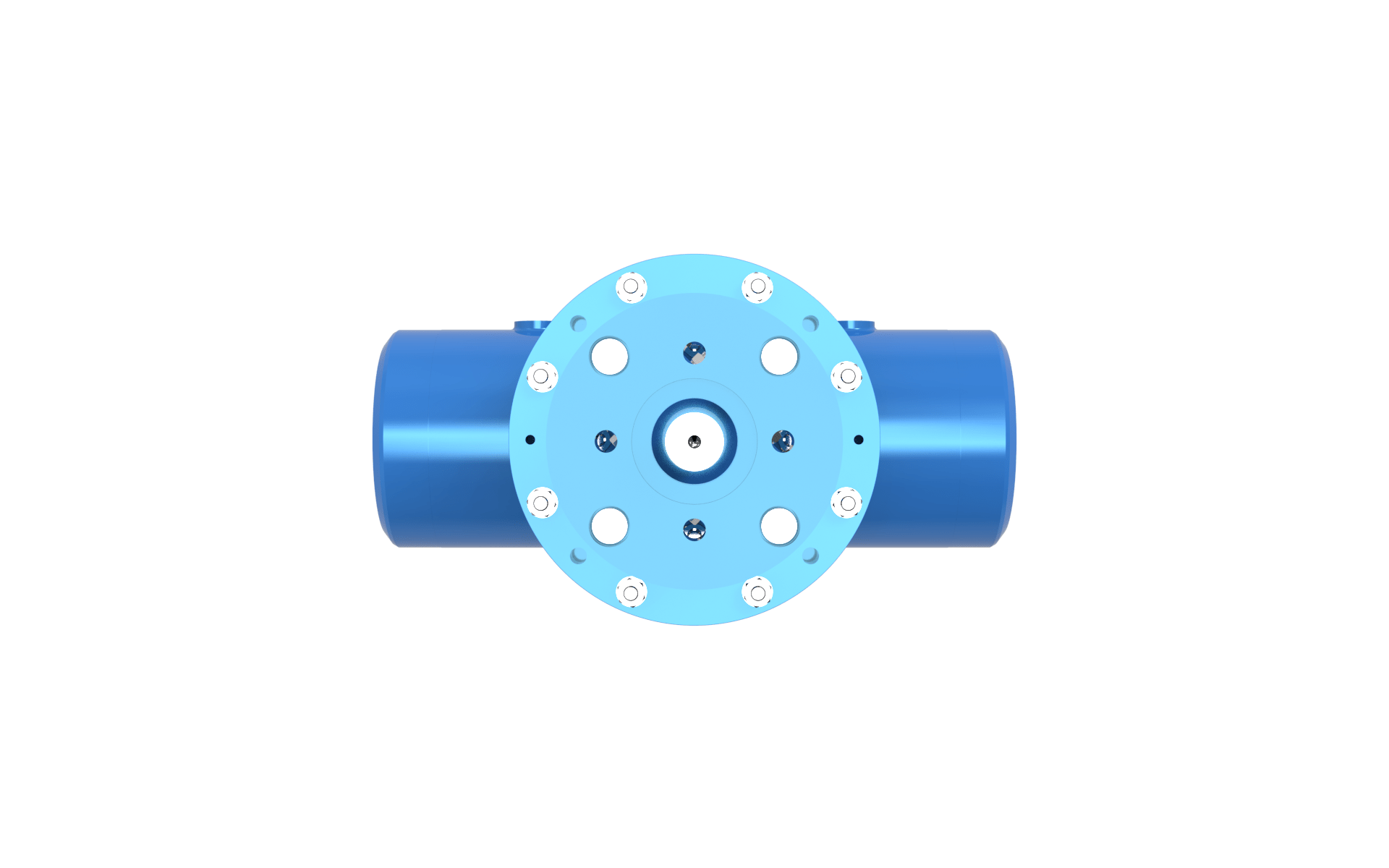

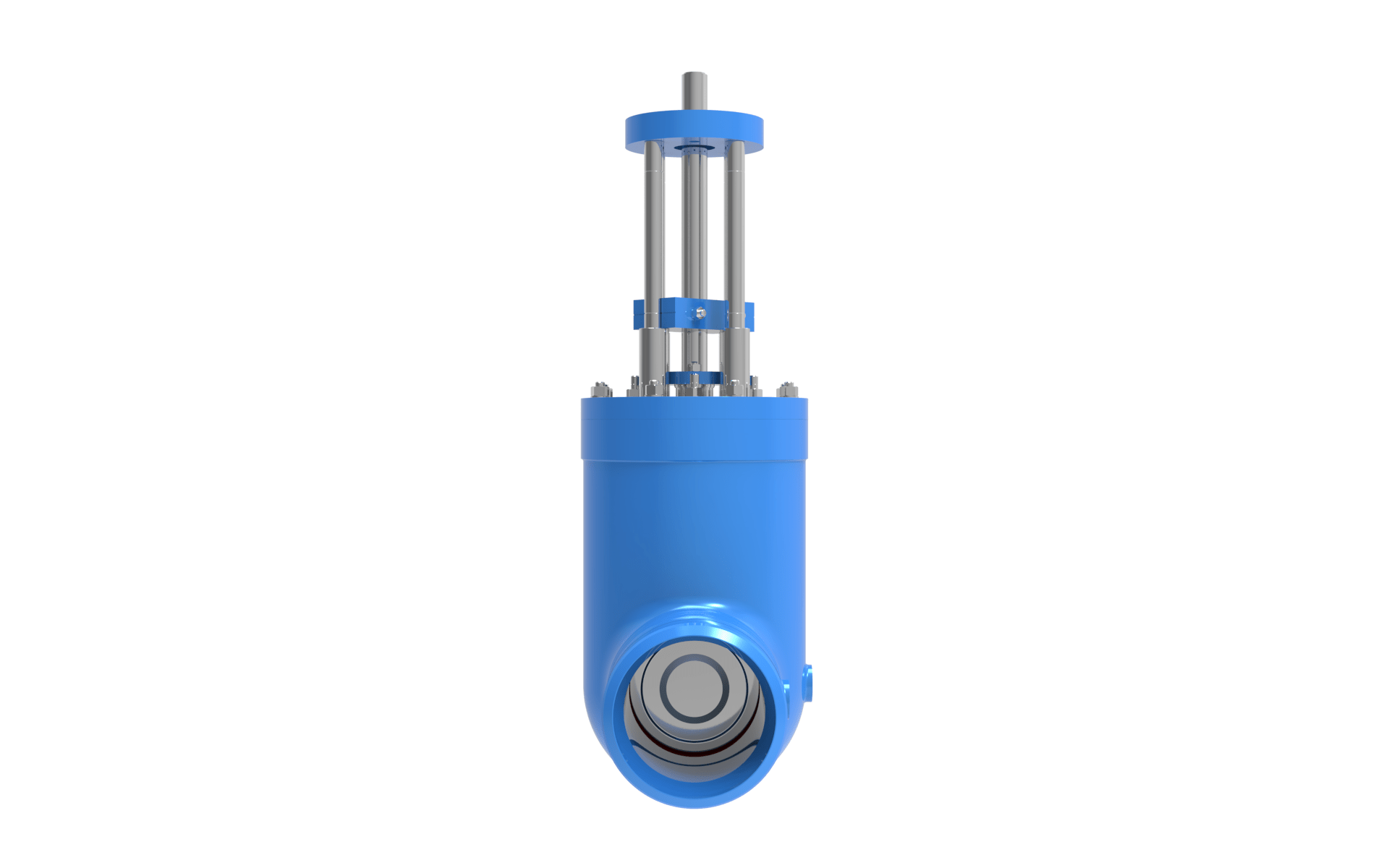

VENTURI DESIGN

- The Venturi design is used when a slightly higher pressure drop is acceptable. The well established principle of fluid flow through a Venturi is used in order to minimise pressure drop. Venturi valves incorporate the design feature of an eye follower.

- In the fully open position, the eye follower bridges the gap between the seats thus giving a smooth flow path and completing the Venturi profile.

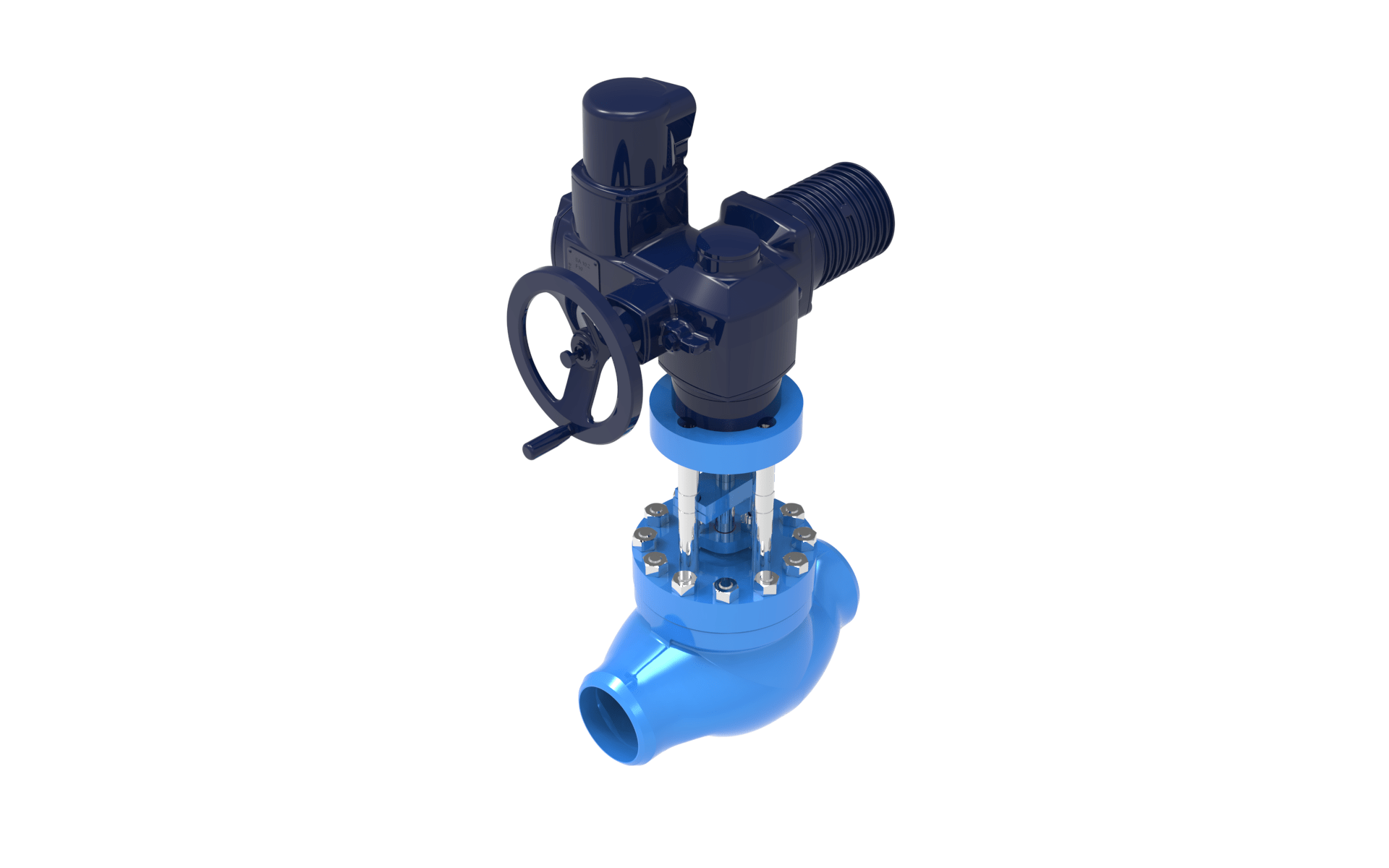

APPLICATIONS

- General purpose stop valve

- Main steam and feedwater isolation

- Boiler circulating pump isolation

- The basic design is also incorporated in valves for other duties such as: Feedwater heater protection; Feed pump leak-off; Nuclear Applications (ASME Section III, Class 1, 2 & 3) (Described in other publications available on request); Regulating duty with V-ported seat

DESIGN RATINGS

- ASME Class 150 to 4500

MATERIALS

- Carbon Steel

- Alloy Steel

- Stainless Steel

- F91 Austenitic Stainless Steel

- Bronze

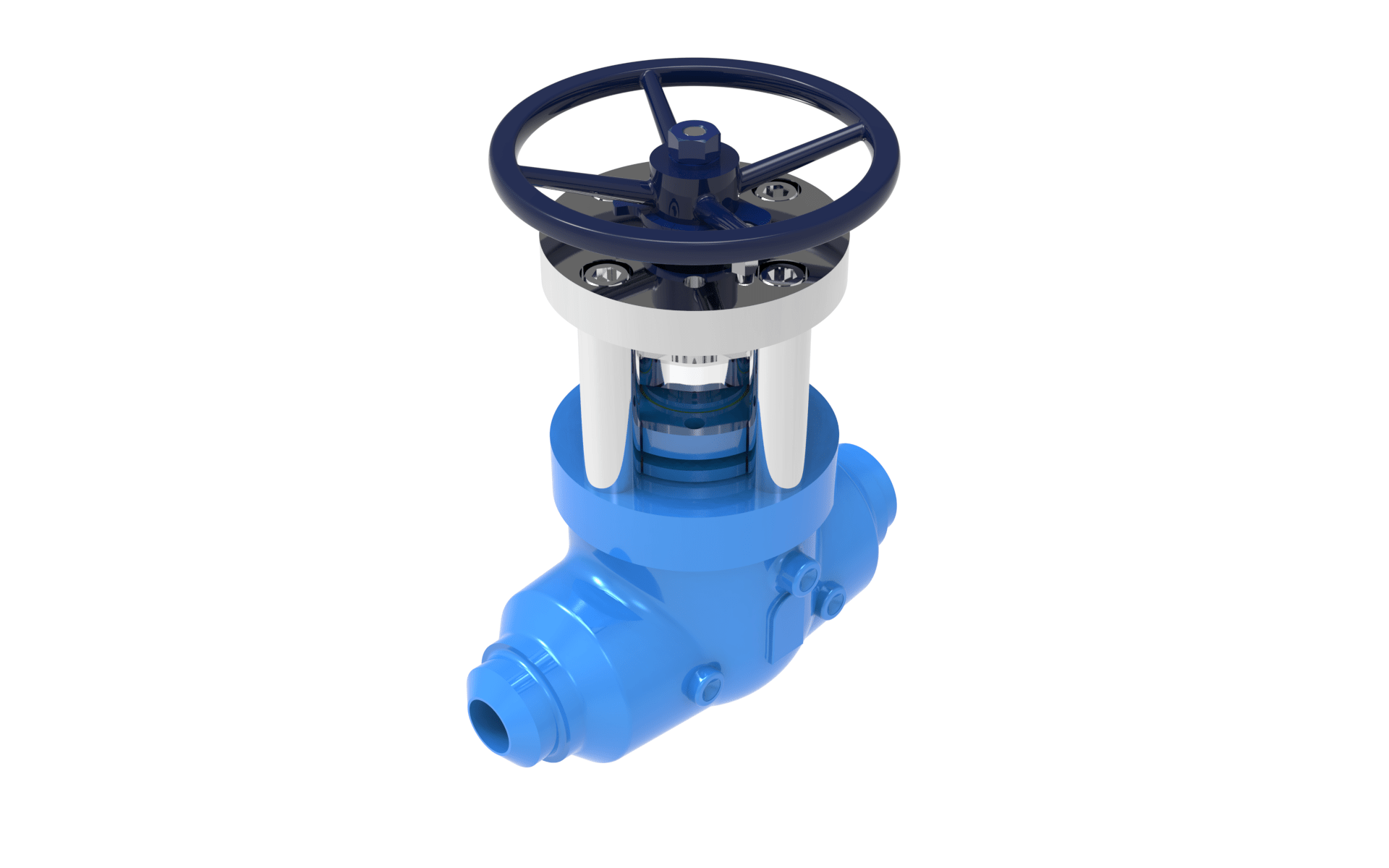

KEY FEATURES & BENEFITS

- Fluid tightness achieved by fluid pressure, not from mechanical wedging action thus eliminating thermal binding

- Complete flow isolation in either direction

- Minimum pressure drop

- Freedom from leakage independent of temperature or pressure changes

- Self-aligning fully supported discs

- Inherent self-cleaning action

- In-line maintenance

- Valves can be offered to incorporate features such as quick closure, live loaded gland, double stuffing box with lantern ring and bleed-off point, back seat, seal welded body & cover joint

DESIGN STANDARDS

- ASME B16.34.

- Alternatively, valves can be supplied to other national standards, ASME section IIIRCC-M

SIZE RANGE & DIMENSIONS

- 15 – 1200 mm (0.5 – 48 inches)

TEMPERATURE RANGE

- 29°C – 620°C (-20°F – 1150°F)