Blakeborough®

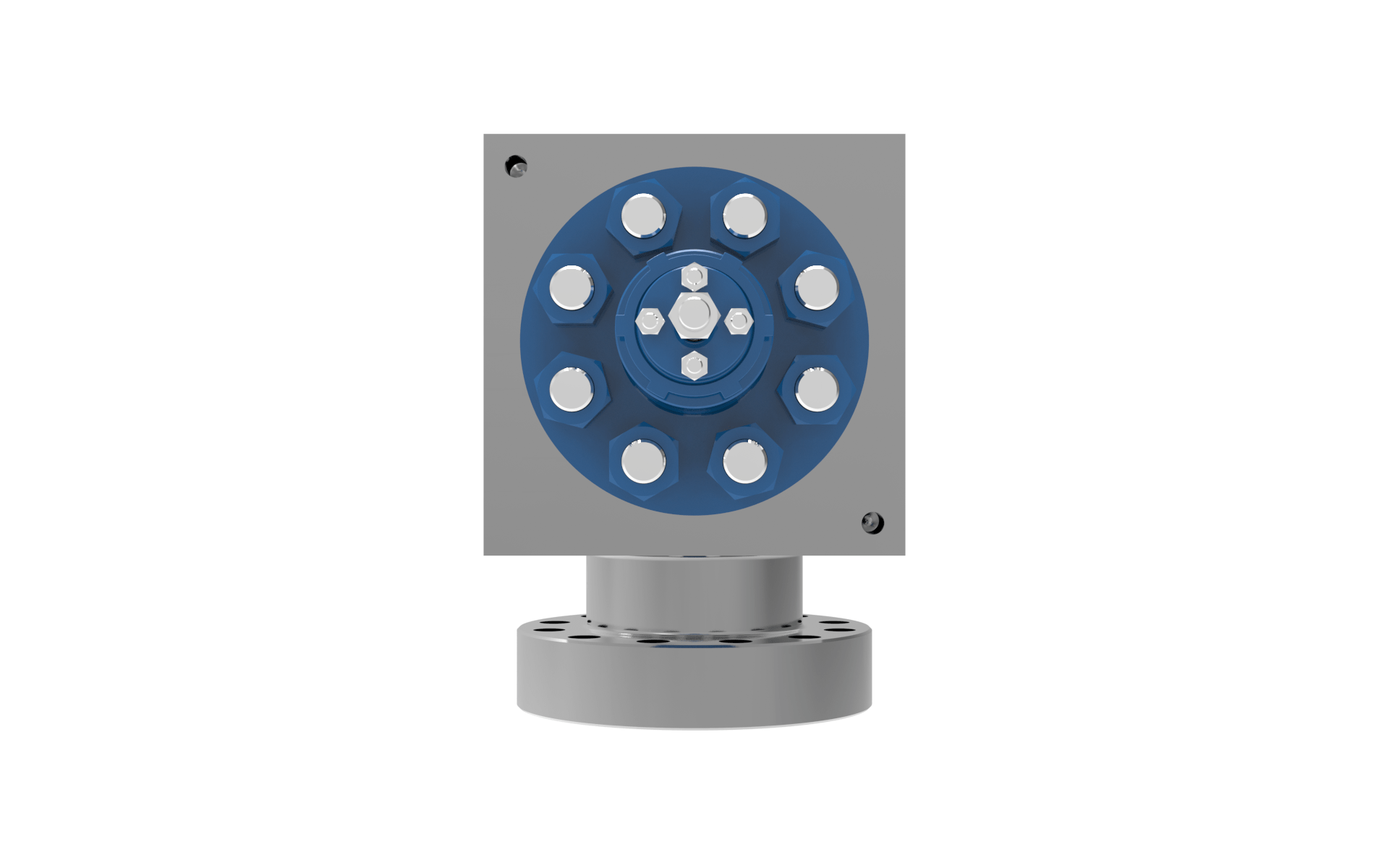

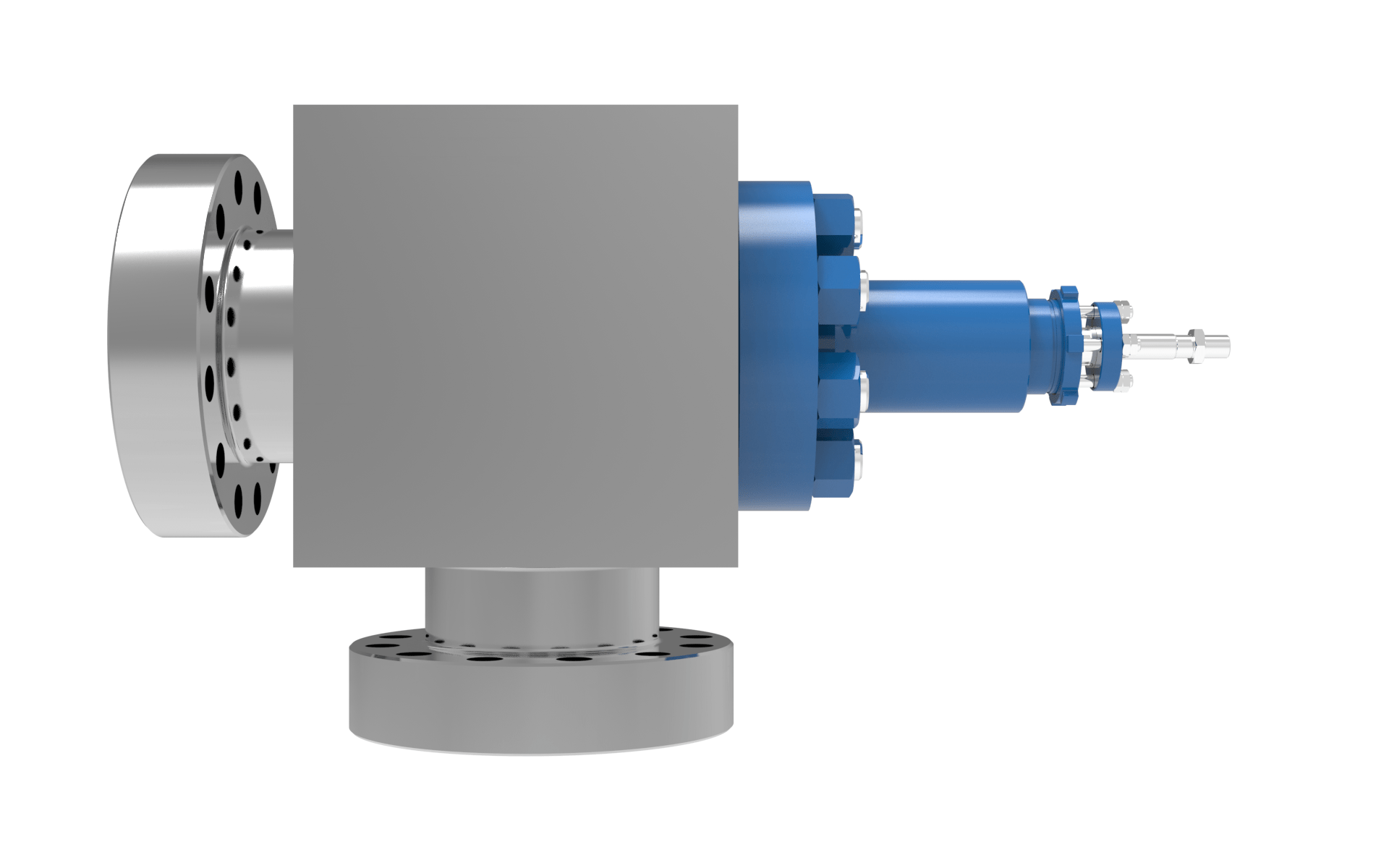

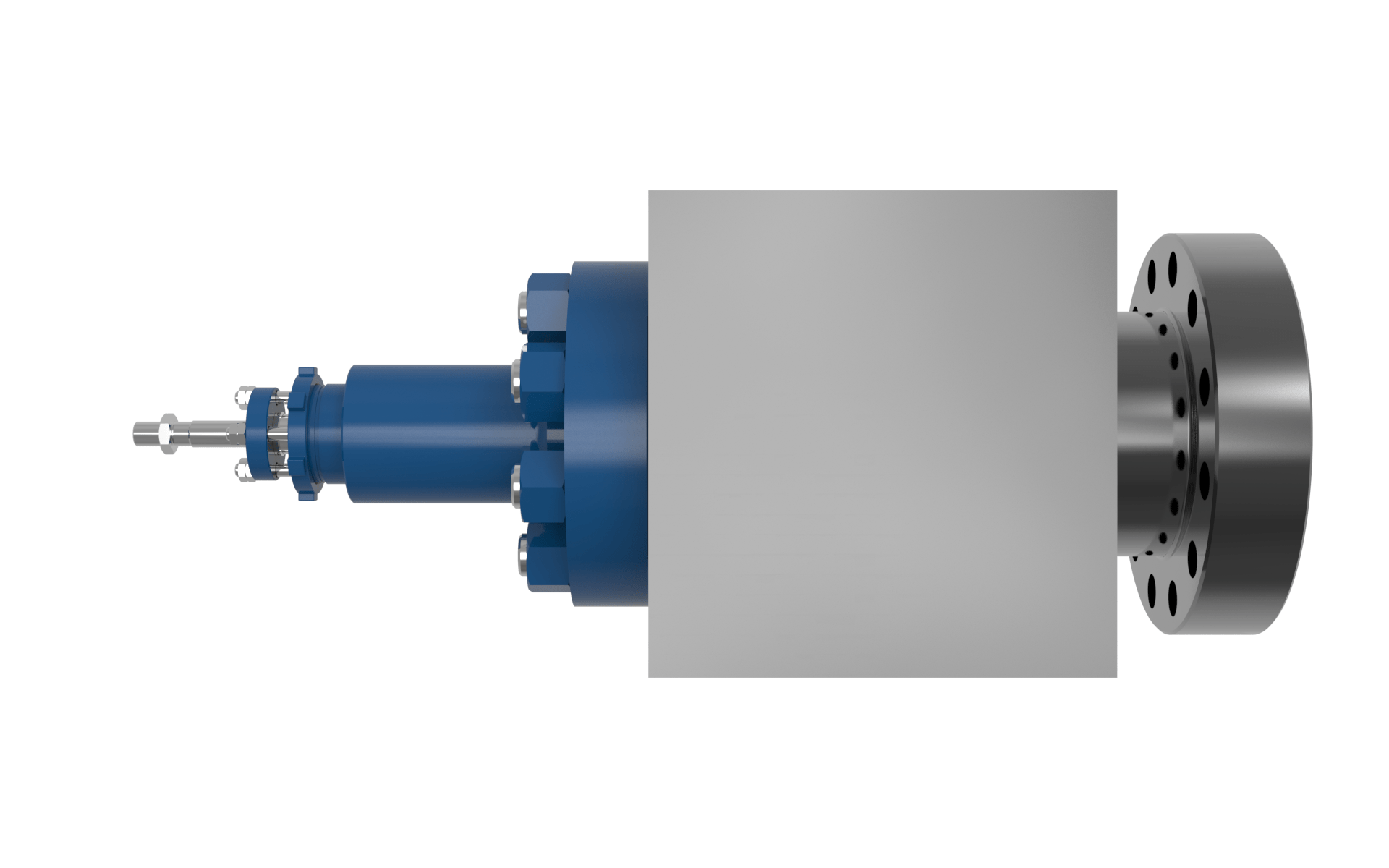

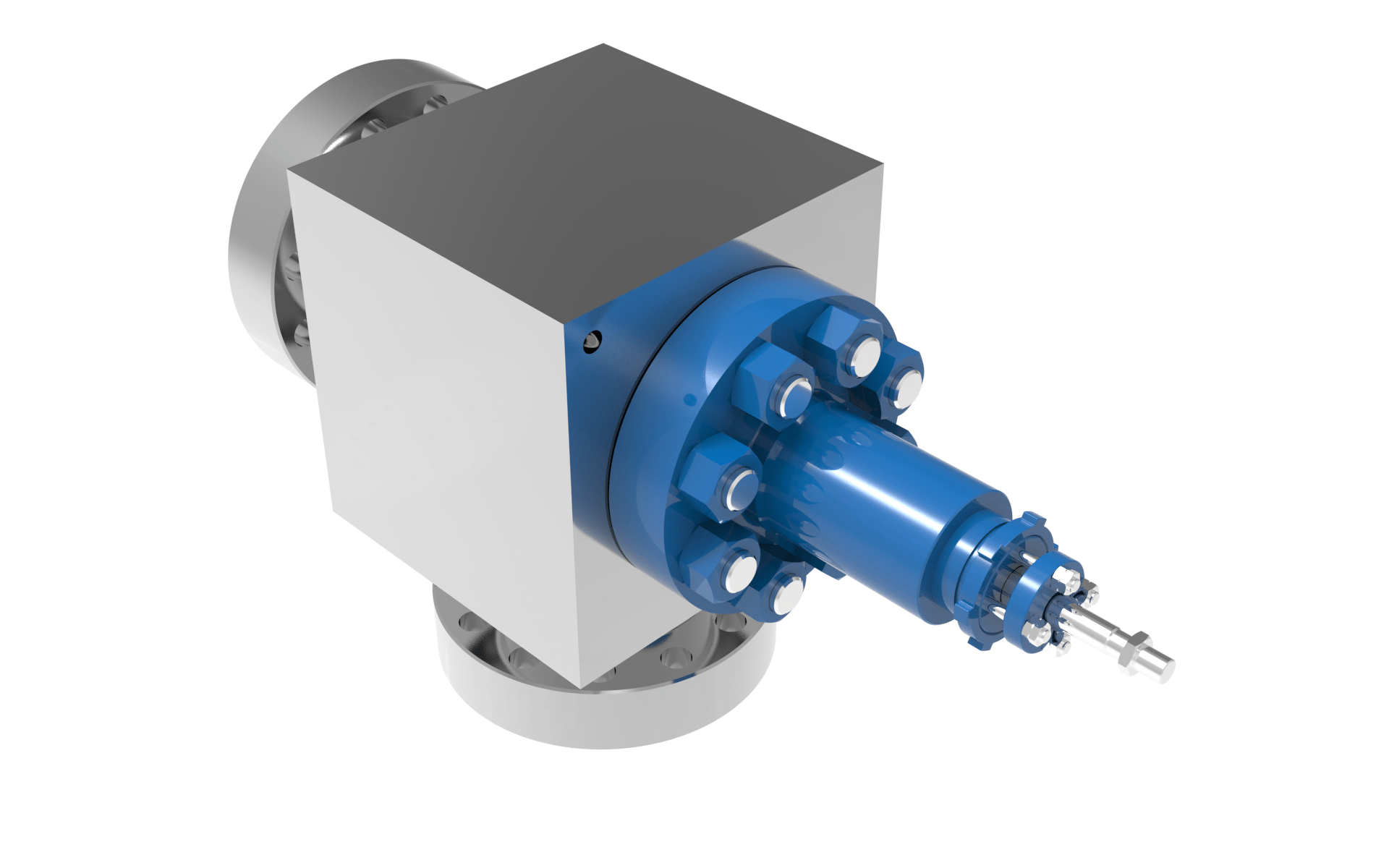

X-Stream™ trim for severe services

The Blakeborough® X-Stream™ represents state of the art technology in severe service trim applications. Combining different velocity control methods it eliminates at the root problems related to cavitation, erosion, noise, or vibration.

The Blakeborough® X-stream™ concept derives from intuition refined by sophisticated simulation techniques and is validated by accurate testing and hundreds of installations. Its design develops the traditional concept of disk stack multistage trim to its maximum potential combining the effect of three different methods of velocity reduction. At the same time it minimizes the risk of blockage in case of solids and achieves high capacity resulting in compact dimensions. X-stream™ is the only trim that ensures total velocity control: fluid velocity is not limited only at trim exit, but throughout the flow path.

KEY FEATURES & BENEFITS

- Elimination of erosion, cavitation, noise, and vibration thanks to highly efficient fluid velocity reduction achieved by combining three methods of energy dissipation: 1) change in direction of the fluid imposed by obstacles in the flow path; 2) expansion – contraction imposed by single passages venture-style shape 3) jets self-impingement induced by the intercommunication among contiguous passages. Total velocity control: fluid velocity is controlled and limited throughout the flow path, not only at the trim exit.

- Natural anti-clogging geometry optimized to guarantee no zones of flow recirculation, minimal risk of blockage due to solids. Compact high capacity design: can be fitted in the same body as a cage trim.

- Advanced design validated by CFD simulation, laboratory testing, and field experience. Abates aerodynamic noise preventing shock cells formation through enhanced jet control design that avoid jets recombination at trim exit.

- Suitable for high temperature gradients as geometry does not present high stress points.

TEMPERATURE RANGE

- – 196ºC – 800ºC (-321ºF – 1472ºF)

APPLICATIONS

- High DP and in general severe service both for liquid and gases, with or without presence of solid contaminants

DESIGN STANDARDS

- ISA 75.01

SIZE RANGE & DIMENSIONS

- 50 – 400mm (2 – 16 inches) plug size

MATERIALS

- 316SS

- 410SS

- Inconel

- Tungsten Carbide

UPGRADES & ADAPTATIONS

- Fully customizable design: special control characteristics

- Bespoke CV values

- Increased velocity reduction for ultra-high pressure drops